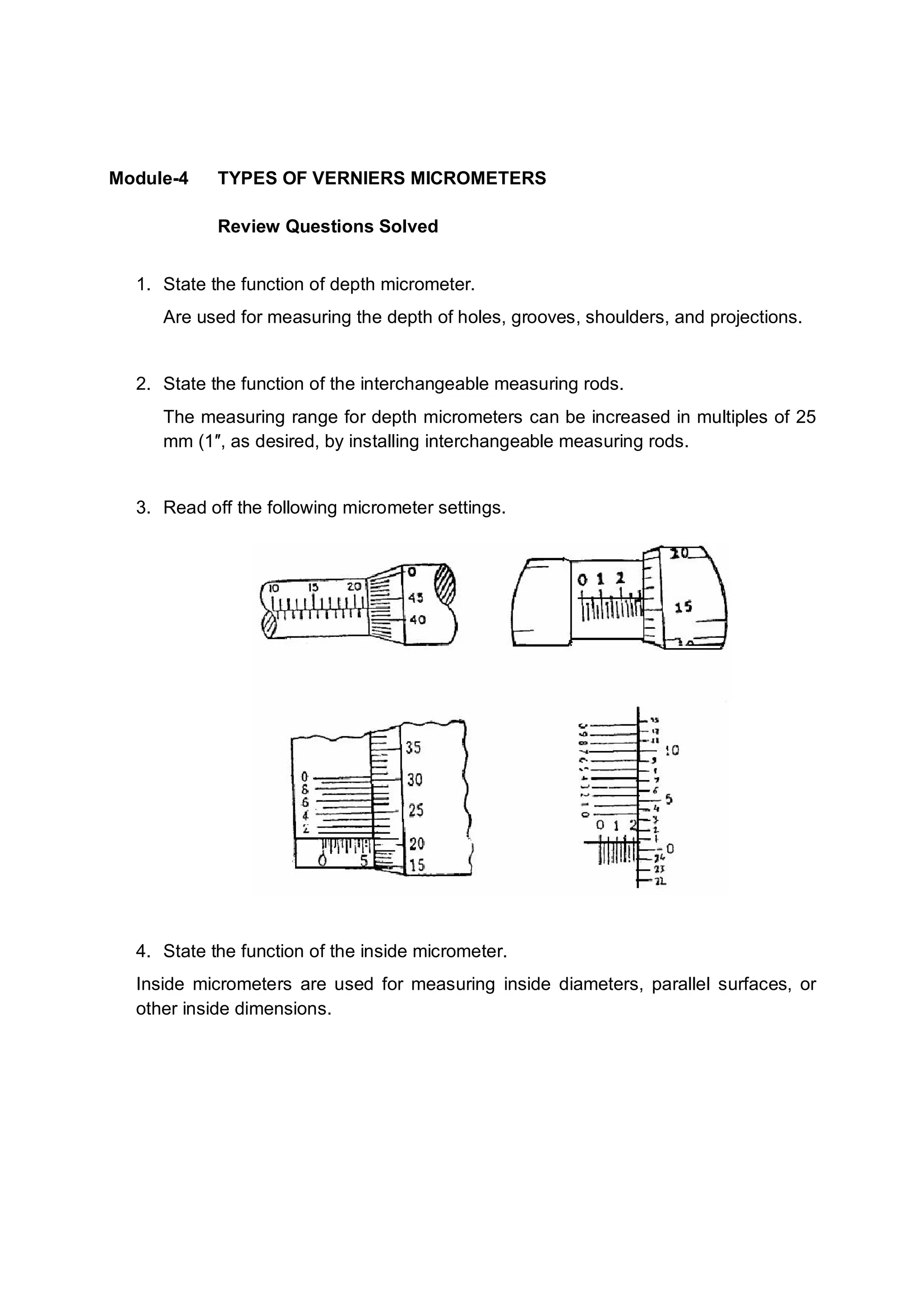

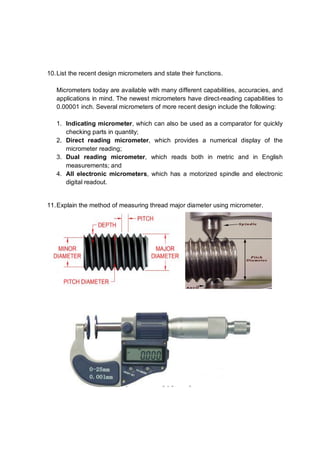

The document discusses different types of vernier micrometers used for various measuring applications. It describes depth micrometers which measure depth, inside micrometers which measure inside diameters and surfaces, and tubular inside micrometers which are useful for internal cylindrical measurements. It also discusses micrometer parts like the ratchet, lock nut, and changeable anvils. Methods for measuring thread diameters and pitches using special thread micrometers are provided. Recent micrometer designs include indicating, direct reading, dual reading, and all-electronic models.