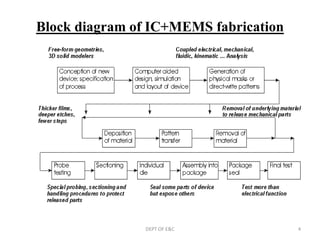

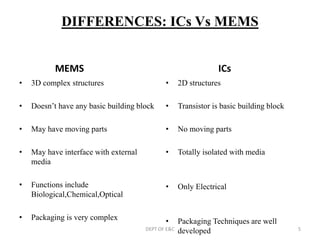

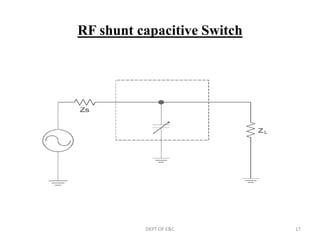

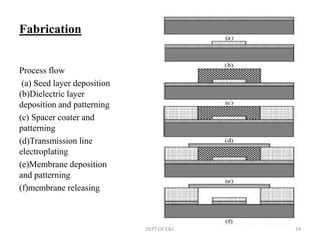

This document discusses Micro-Electro-Mechanical Systems (MEMS) technology. It begins with an introduction to MEMS and differences between MEMS and integrated circuits. It then describes basic MEMS elements and the manufacturing processes, including photolithography, micromachining, and laser micromachining. RF MEMS switches are discussed next, including series contact and shunt capacitive switches. Fabrication processes and comparisons with solid state switches are provided. Applications of MEMS in various fields are mentioned. The document concludes that MEMS switches are an alternative to solid state switches due to their low power consumption and high isolation.

![References

[1] Sazzadur Choudhury, M. Ahmadi, and W.C. Miller, “Micromechanical system

for System-on-Chip Connectivity”, IEEE Circuits and Systems, Page(s) 112-132

September 2002

[2] J. B. Muldavin, G. M. Rebeiz, "High Isolation RF MEMS Shunt Switches-Part

2: Design", IEEE Tran. On Microwave Theory and Techniques, Vol.6, Page(s):

253-276.

June 2000,

[3] P. Osterberg, H. Yie, X. Cai, J. White, and S. Senturia, “Self-consistent

simulation and modeling of RF MEMS,“ in Proc. IEEE MEMS Conf. January 1994,

Page (s)28-32.

[4] Gopinath. A and Ranklin.JB, IEEE Electronic development,” GaAs FET RF

switches “, vol. 12, Page(s) 18-37, August 2003

DEPT OF E&C 25](https://image.slidesharecdn.com/mems-140518021806-phpapp01/85/Mems-technology-ppt-25-320.jpg)