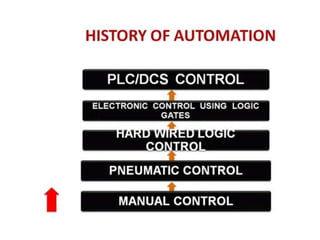

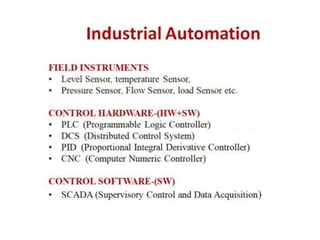

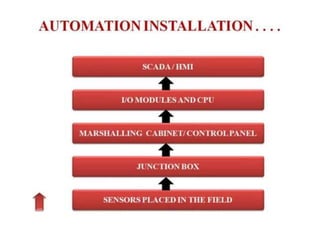

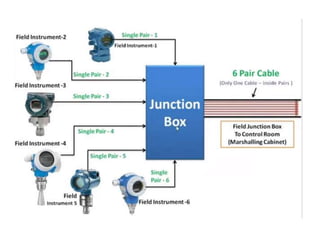

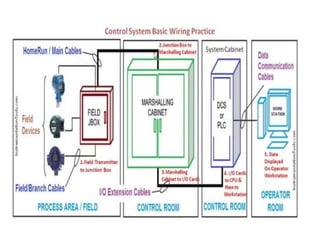

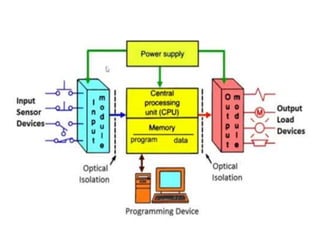

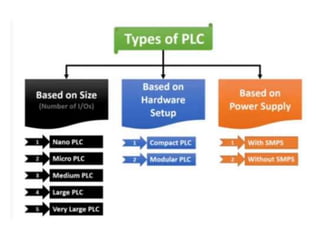

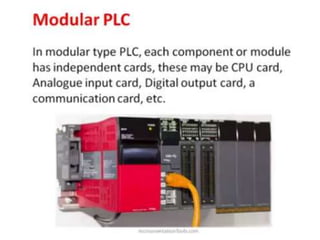

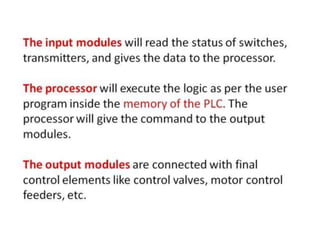

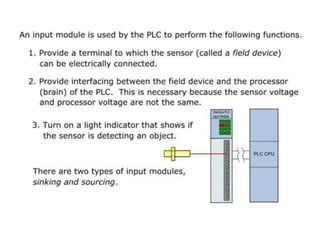

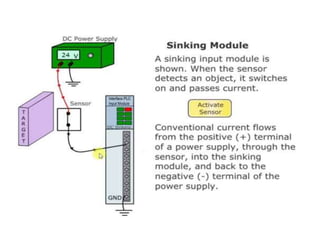

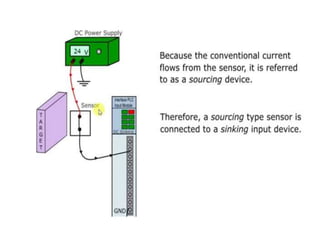

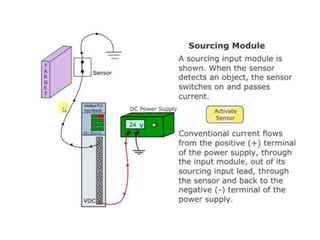

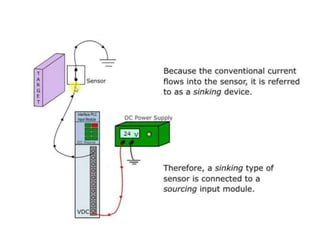

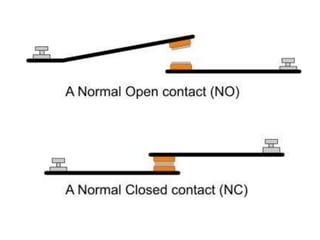

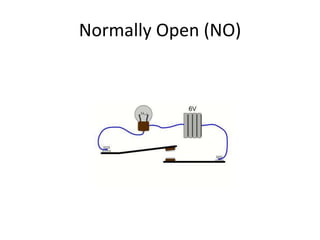

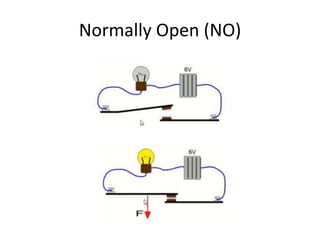

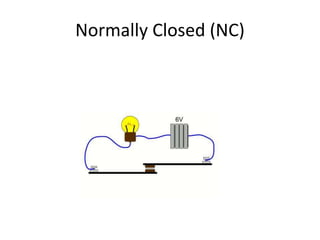

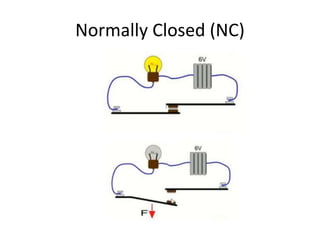

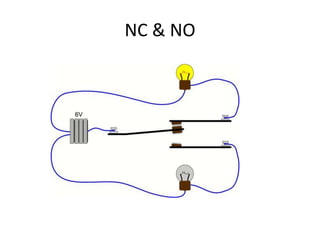

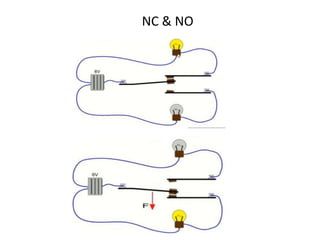

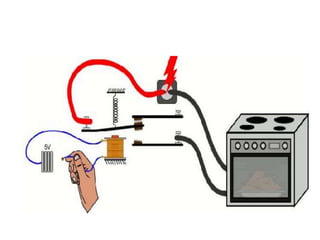

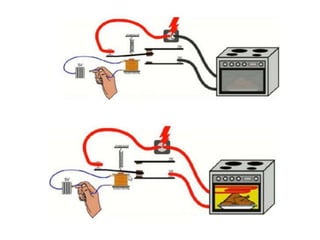

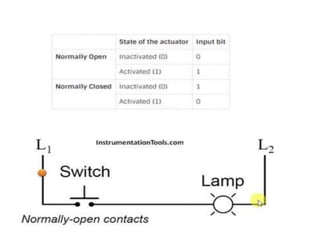

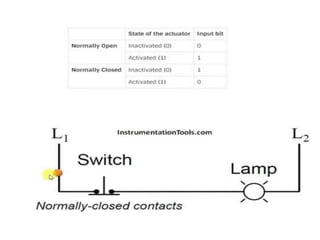

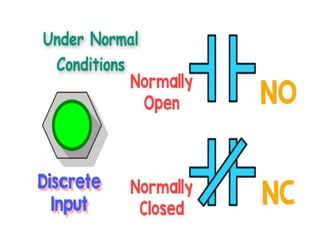

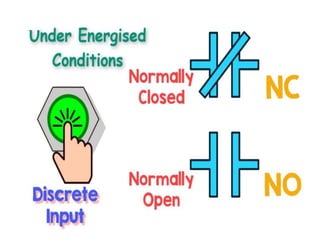

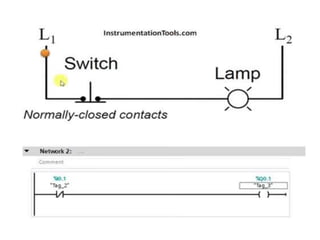

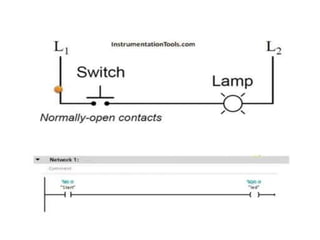

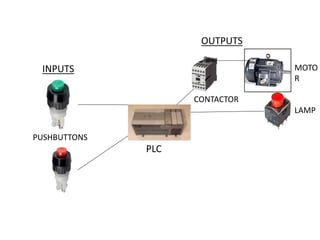

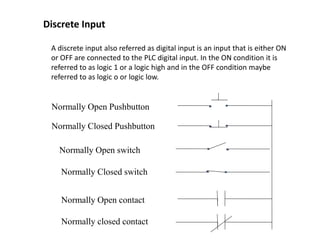

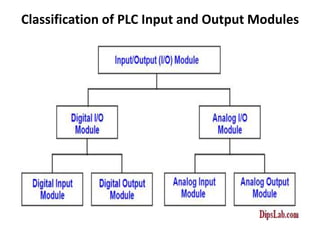

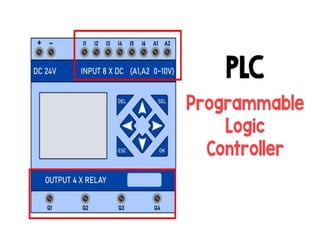

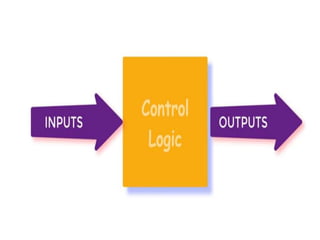

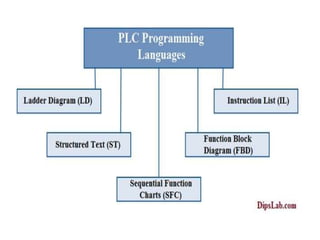

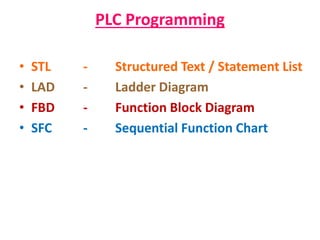

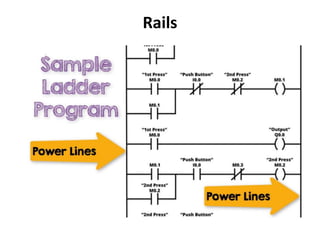

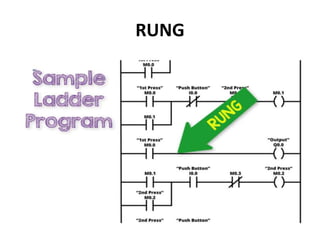

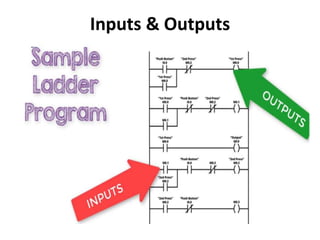

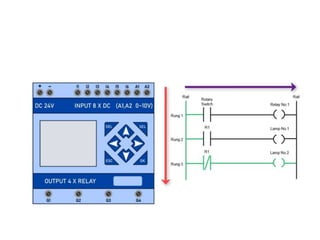

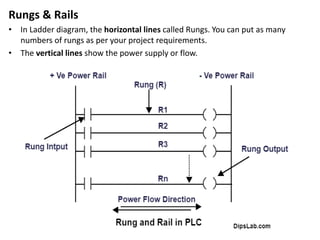

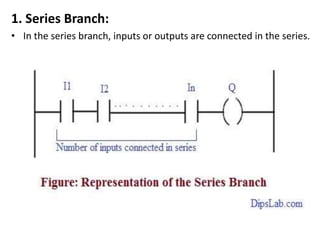

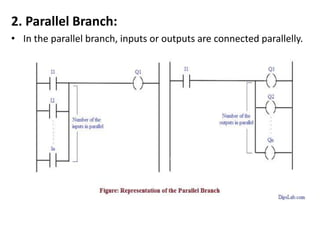

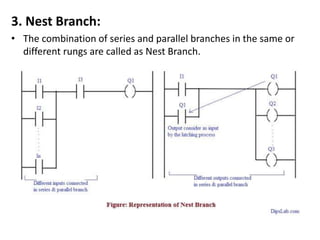

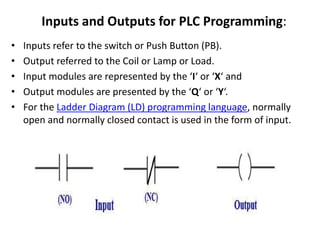

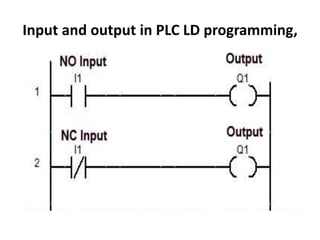

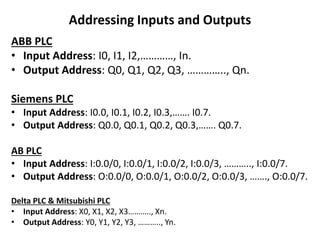

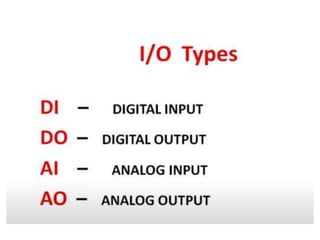

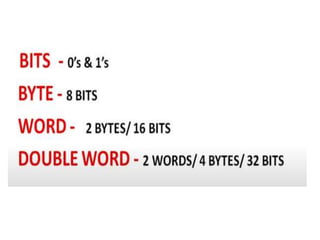

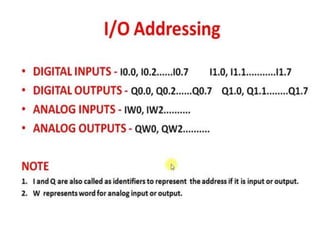

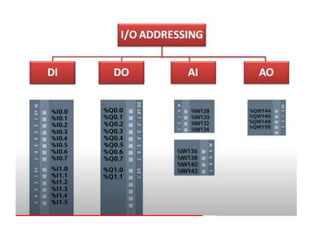

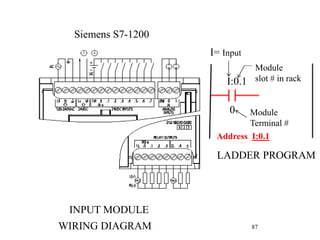

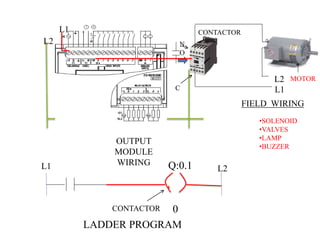

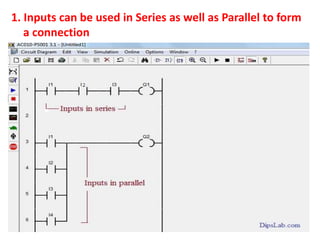

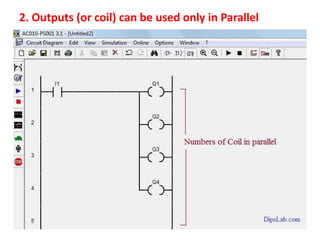

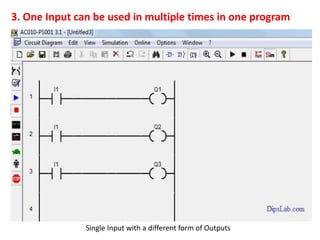

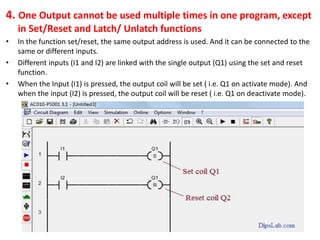

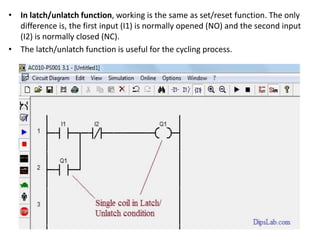

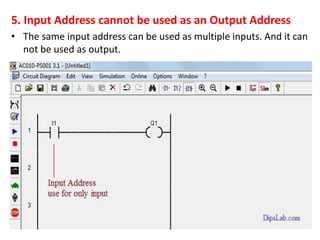

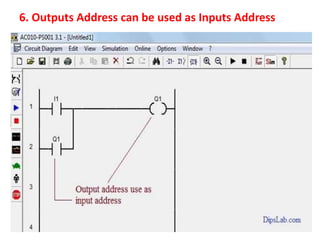

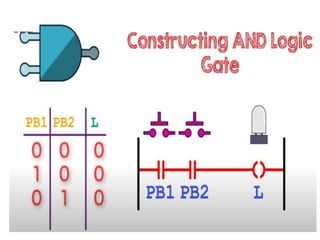

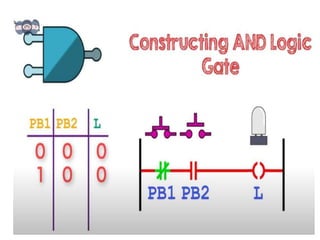

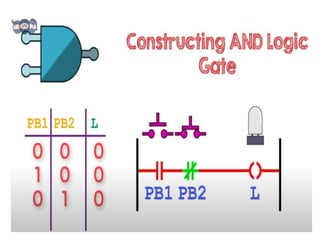

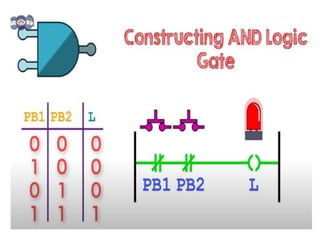

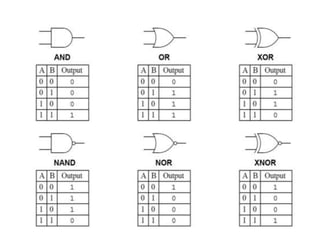

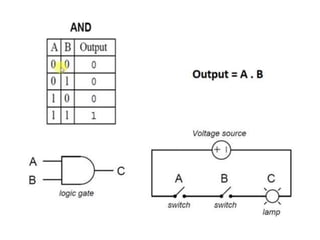

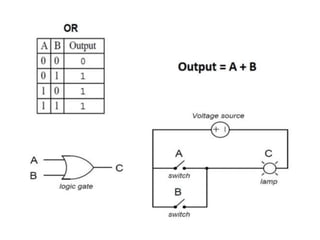

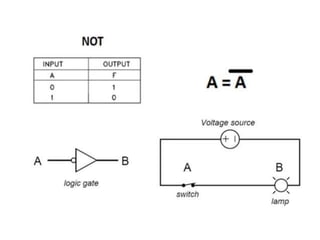

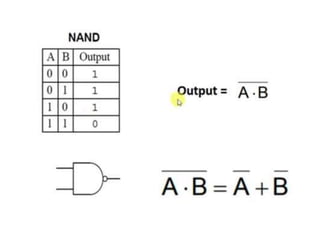

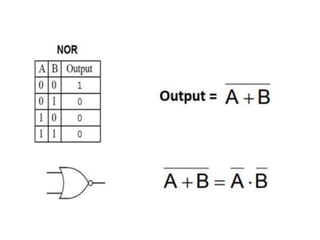

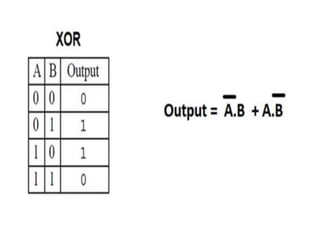

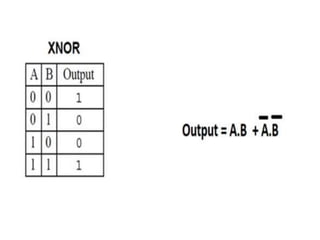

This document discusses industrial automation and PLC programming. It describes normally open and normally closed contacts, different types of PLC inputs and outputs like pushbuttons, relays, and motors. It also summarizes the different types of PLC modules like digital and analog I/O modules. The rest of the document focuses on ladder logic programming, describing basic components like rungs and branches, addressing inputs and outputs, and instructions. It provides examples of ladder logic for common logic gates like AND, OR, NAND, NOR, and XOR.