mechanics of structure(CE3G)- simple stress & strain.ppt

•Download as PPT, PDF•

0 likes•103 views

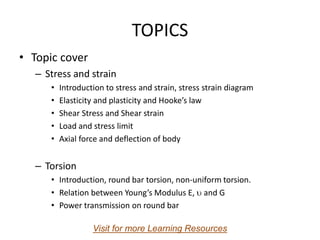

This document covers topics related to stress and strain including: - Definitions of stress as force per unit area and strain as deformation per original length. Stress is proportional to strain below the proportional limit according to Hooke's law. - The stress-strain diagram shows elastic behavior, yield point, plastic deformation, strain hardening, necking and fracture. - Shear stress is defined as force per unit area applied sideways. Shear strain is the ratio of deformation to original height. Shear modulus relates shear stress and strain. - Materials have ultimate tensile, compressive and shear stresses at which they fail. Design allows only a fraction of these stresses for safety.

Report

Share

Report

Share

Recommended

Connections in steel structures

Connections are devices used to join structural elements together to safely transfer forces between them. There are different types of connections classified by their means of connection, such as welded, riveted, and bolted, and by the forces transferred, such as truss connections, fully restrained connections, and partially restrained connections. Fully restrained connections provide continuity between structural members and allow over 90% of moment to be transferred to provide greater flexural resistance. Partially restrained connections have less rigidity than fully restrained connections and allow some percentage of moment and full shear to be transferred. Semi-rigid connections provide rigidity between fully restrained and simple connections and transfer approximately 20-90% of moment.

Portal frame 1

Steel portal frames are a common form of construction for single-story industrial buildings. They consist of parallel steel frames forming the major structure, with steel columns connected by steel beams or rafters spanning between them. This allows for large clear spans of up to 40 meters. The frames are spaced 5-10 meters apart and support the roof structure and unobstructed floor space within. Concrete or masonry walls can be attached to the frames.

Planar Truss | Civil Engineering

A planar truss is the one whose all members lies in a single plane. If a plane truss does not change its shape when loaded then it is known as Rigid Planar Truss. Copy the link given below and paste it in new browser window to get more information on Planar Truss:- http://www.transtutors.com/homework-help/civil-engineering/planar-truss/

TRUSS 2020.pptx

A truss is an assembly of members such as beams, connected by nodes, that creates a rigid structure. In engineering, a truss is a structure that "consists of two-force members only, where the members are organized so that the assemblage as a whole behaves as a single object"

Brick walling and joints

This document discusses different types of brick bonds used in masonry construction. It begins by explaining the necessity of bonds, including strengthening the wall, distributing load uniformly, and ensuring quality work. It then describes 12 common bond types such as stretcher bond, header bond, English bond, and Flemish bond. Each bond type is defined through text and diagrams of wall plans and elevations. The document also covers requirements for good bonds and examples of L-joints and T-joints in different bond configurations.

ARCHES AND ITS TYPES

The document provides information about different types of arches including bell arches, ogee arches, pointed multifoil arches, shoulder arches, jack arches, segmental arches, and drop arches. For each arch, it describes the key characteristics, historical background and origins, examples of use in historical buildings, and basic steps for constructing the arch geometrically. Diagrams are included to illustrate the construction process for some of the arch types. The document serves as an educational reference on classical arch forms.

Hagia Sophia Precedent Study & Analysis Sketch & Report

Study & Analysis on spatial organization of Hagia Sophia

Mwsoat anaser al-imara_02

موسوعه العماره الإسلاميه (محاريب-قباب وماذن-اعمده وعقود-عرائس ومقرنصات)

د يحيي وزيري

Recommended

Connections in steel structures

Connections are devices used to join structural elements together to safely transfer forces between them. There are different types of connections classified by their means of connection, such as welded, riveted, and bolted, and by the forces transferred, such as truss connections, fully restrained connections, and partially restrained connections. Fully restrained connections provide continuity between structural members and allow over 90% of moment to be transferred to provide greater flexural resistance. Partially restrained connections have less rigidity than fully restrained connections and allow some percentage of moment and full shear to be transferred. Semi-rigid connections provide rigidity between fully restrained and simple connections and transfer approximately 20-90% of moment.

Portal frame 1

Steel portal frames are a common form of construction for single-story industrial buildings. They consist of parallel steel frames forming the major structure, with steel columns connected by steel beams or rafters spanning between them. This allows for large clear spans of up to 40 meters. The frames are spaced 5-10 meters apart and support the roof structure and unobstructed floor space within. Concrete or masonry walls can be attached to the frames.

Planar Truss | Civil Engineering

A planar truss is the one whose all members lies in a single plane. If a plane truss does not change its shape when loaded then it is known as Rigid Planar Truss. Copy the link given below and paste it in new browser window to get more information on Planar Truss:- http://www.transtutors.com/homework-help/civil-engineering/planar-truss/

TRUSS 2020.pptx

A truss is an assembly of members such as beams, connected by nodes, that creates a rigid structure. In engineering, a truss is a structure that "consists of two-force members only, where the members are organized so that the assemblage as a whole behaves as a single object"

Brick walling and joints

This document discusses different types of brick bonds used in masonry construction. It begins by explaining the necessity of bonds, including strengthening the wall, distributing load uniformly, and ensuring quality work. It then describes 12 common bond types such as stretcher bond, header bond, English bond, and Flemish bond. Each bond type is defined through text and diagrams of wall plans and elevations. The document also covers requirements for good bonds and examples of L-joints and T-joints in different bond configurations.

ARCHES AND ITS TYPES

The document provides information about different types of arches including bell arches, ogee arches, pointed multifoil arches, shoulder arches, jack arches, segmental arches, and drop arches. For each arch, it describes the key characteristics, historical background and origins, examples of use in historical buildings, and basic steps for constructing the arch geometrically. Diagrams are included to illustrate the construction process for some of the arch types. The document serves as an educational reference on classical arch forms.

Hagia Sophia Precedent Study & Analysis Sketch & Report

Study & Analysis on spatial organization of Hagia Sophia

Mwsoat anaser al-imara_02

موسوعه العماره الإسلاميه (محاريب-قباب وماذن-اعمده وعقود-عرائس ومقرنصات)

د يحيي وزيري

Lecture 07: Islamic Architecture in India_Tughlaq Dynasty

This is a class lecture on Islamic Architecture in India. Architecture of Tughlaq Dynasty has covered in this lecture.

Course Title: Architectural Heritage-IV

Architecture Discipline,

Khulna University, Khulna

TENSILE STRUCTURE | ARCHITECTURAL CONSTRUCTION

This document discusses tensile structures and fabric structures. It describes different types of tensile structures like suspension bridges and cable trusses. It also discusses different types of fabric structures like saddle roofs and mast-supported roofs. The document outlines various coated and open-mesh fabrics that are used in tensile and fabric structures, including PVC, THV, PTFE, and ETFE materials. It notes advantages like unique designs and high strength-to-weight ratios, as well as disadvantages like brittleness and loss of stability if tension is lost.

Timber structure

This document discusses timber as a structural building material. It notes that timber is a renewable resource with low environmental impact compared to other materials. Timber structures use vertical posts and horizontal beams. As a structure, timber can transmit and resist loads through axial compression and bending. Properties like stress, deflection and strength depend on factors like grain direction, load type and material properties. Timber combines well with other materials like steel and concrete in composite structures.

Trusses

TRUSS IS A BRIEF TOPIC TO READ BUT I AM TRY TO THE SOME IMPORTANT TERMS TO MENTIONS IN THIS PRESENTATION

Japanese Architecture

The document discusses the architecture of Japan's Kansai region across different historical periods. It notes that the oldest existing buildings in Japan are from the Asuka period in the 7th century and were made of wood. Architecture evolved during the Heian period with the introduction of ceramic tile roofs and wood flooring. A notable example from this era is the Phoenix Hall built in 1053 near Kyoto. Architecture further developed during the Kamakura period through influences from Korea and China, featuring wooden construction and tile roofs. After World War 2, modern steel and concrete buildings replaced traditional wooden structures as Japan rebuilt its cities.

Roofs

The document discusses different types of roofs, their components, and considerations for design. It describes roofs as the uppermost part of a building that protects it from weather using structural elements and coverings. The main types are pitched, flat, and curved roofs. Pitched roofs are suitable for heavy rainfall areas and have simple shapes, while flat roofs can be used on buildings of any size or shape, especially in hot and dry regions. Key elements of roofs include the pitch, coverings, rafters, purlins, ridges, and eaves. Single roofs like lean-to and couple roofs have limited spans, while double roofs using purlins can support longer spans.

Rigid frame systems

The document discusses rigid frame systems used in high-rise buildings. It provides a history of rigid frames, an introduction to what they are, and examples of their applications. It describes the material properties and connections used. It discusses considerations for rigid frame design like behavior under lateral loads. It notes advantages like architectural freedom but also disadvantages like increased drift. It concludes with a case study on using hybrid rigid/semi-rigid frames to improve seismic performance.

Steel Structure Design (Study Report).pptx

This document provides an overview of steel structure design. It discusses the types of steel structures like truss, frame, grid and arch structures. It describes the methodology of steel design using Allowable Strength Design and Load and Resistance Factor Design. It discusses the mechanical properties of steel, concepts of limit state design for beam columns, and connections. It also provides details on the design of beams, including classifications of beams and the main considerations in beam design.

Design of singly reinforced sections Using First Principales - تصميم القطاعات...

مُلخصات طالب فيما يخص مادة تصميم المنشآت الخرسانية المسلحه

Steel sections-Building Construction

This document discusses different types of structural sections used in construction, including steel trusses, tubular sections, and angle sections. It provides an overview of trusses, describing their main components and different types of truss configurations. Tubular sections or hollow structural sections are discussed next, outlining their manufacturing process and common uses in buildings, bridges, and other structures. Finally, the document examines angle sections, defining their types, sizes, fixing details, and applications for reinforcement, support, framework, and decoration.

Steel Roof Truss

This document summarizes steel roof trusses. Most building roofs can be framed with prefabricated light-gauge steel trusses, which offer a high-strength, lightweight roof system that can be installed quickly. Steel trusses are manufactured from C-shaped galvanized steel and are stronger than wood trusses. They are constructed by connecting chord and web members made of steel into triangular shapes, then bolting or welding them together on the ground before installing the completed truss on the roof. All steel roofing has a protective metallic coating to prevent rusting.

Basic structure

Basic beam column structure construction and examples and lastly shell structure in short.

Rafiq azam buildings.Richerd Mier, Le Corbusier, Tadao Ando residences.

Bangladesh Liberation War museum

Sydney opera house

Unit 7 interpenetrations of solids

1. When two solids intersect, their surfaces meet along a curve called the curve of intersection. This curve is common to both solids.

2. Curves of intersection show the exact maximum surface contact between two solids, which is important for making strong, leak-proof joints when solids are joined together.

3. The document provides examples of determining the curve of intersection for various solids penetrating each other, such as cylinders, prisms, and cones. The method involves drawing three views and transferring points of intersection between views.

L16_17_Shell structures.pdf

Shell structures are thin curved structures that are efficient at using materials. They can be found in nature and are used for industrial and architectural structures like silos, tanks, and roofs. Shells are difficult to analyze due to their complex behavior under loads. Different types of shells include elliptic paraboloids, hyperbolic paraboloids, and circular cylinders. Buckling is an instability issue for shells where they change shape under load. Several methods are used to analyze shells including finite element analysis, membrane theory, and bending theory equations.

FLITCHED BEAMS

This document discusses flitched beams, which are composite beams made of wood beams sandwiched around a steel plate and held together with bolts. It defines beams and types of beams, then explains what composite beams and flitched beams are. It describes the design principle of flitched beams, which combines the properties of wood and steel to provide greater strength than either material alone. Applications of flitched beams include construction of houses and decks where they are stronger than wood but lighter than steel. However, engineered wood has replaced flitched beams due to lower costs and easier installation.

Support reactions

Types of Beam

Types of Loads acting on beam

Types of Supports

Instrument used for finding “Support Reactions”

How to find “Support Reactions”

SURFACE ACTIVE STRUCTURES(structure systems)

Basic and simplified introduction of Shell and Dome structures for Architects and Structural Engineer and students of related streams.

ARCHES AND DOMES

The document discusses different types of arches and domes and their construction techniques. It provides details on the key components of arches like voussoirs, keystone, intrados, etc. It describes various arch forms including flat arch, corbelled arch, triangular arch, semicircular arch, bullseye arch, Islamic arch, segmental arch, and pointed Gothic arch. It also explains dome structures and provides examples of different dome styles such as onion domes, geodesic domes, corbel domes, parabolic domes, saucer domes, and umbrella domes. The document aims to educate about the forms and building of common arch and dome structures.

Mega prefab post tension catalog

Mega Prefab is a complete service provider of structural precast and post-tensioned concrete. We are involved in all the phases of the project. We will design, manufacture, deliver and install our products. With more than 16 years experience in the business, we have optimized our structural elements to be efficient, safe and low cost.

Types of beam & types of supports

This document discusses different types of beams and supports used in engineering mechanics. It describes four types of supports - fixed, simple, roller, and hinged - based on how they restrict the movement of beams. It also outlines six types of beams defined by their support conditions: fixed, cantilever, simply supported, overhanging, continuous, and combinations of these. Finally, it categorizes loads as point, uniformly distributed, or uniformly varying based on how forces are applied along the beam.

Stess strain basic concept

This document provides an overview of stress, strain, and modulus of elasticity concepts in mechanical engineering. It defines stress as force per unit area, strain as the deformation per original length. Hooke's law states deformation is directly proportional to force. The modulus of elasticity E is the constant of proportionality between stress and strain. A stress-strain diagram is presented showing the elastic region, yield point, plastic region, strain hardening, and necking behavior. Shear stress and modulus of rigidity G are also defined. Design considerations like factor of safety are discussed for selecting allowable loads below ultimate strengths.

Stress strain sm (1) (1)

- Stress is defined as force per unit area and strain is defined as deformation per original length. Direct stress and strain occur when a direct tensile or compressive force is applied.

- A stress-strain diagram shows the relationship between stress and strain. It initially increases linearly as stress is proportional to strain. Beyond the proportional limit, plastic deformation occurs.

- Shear stress is defined as force per unit area of a cross section and acts sideways on a material. Shear stress has a maximum limit called the ultimate shear stress. Tensile stress also has a maximum limit known as the ultimate tensile stress, which is reached if a material is stretched until it breaks.

More Related Content

What's hot

Lecture 07: Islamic Architecture in India_Tughlaq Dynasty

This is a class lecture on Islamic Architecture in India. Architecture of Tughlaq Dynasty has covered in this lecture.

Course Title: Architectural Heritage-IV

Architecture Discipline,

Khulna University, Khulna

TENSILE STRUCTURE | ARCHITECTURAL CONSTRUCTION

This document discusses tensile structures and fabric structures. It describes different types of tensile structures like suspension bridges and cable trusses. It also discusses different types of fabric structures like saddle roofs and mast-supported roofs. The document outlines various coated and open-mesh fabrics that are used in tensile and fabric structures, including PVC, THV, PTFE, and ETFE materials. It notes advantages like unique designs and high strength-to-weight ratios, as well as disadvantages like brittleness and loss of stability if tension is lost.

Timber structure

This document discusses timber as a structural building material. It notes that timber is a renewable resource with low environmental impact compared to other materials. Timber structures use vertical posts and horizontal beams. As a structure, timber can transmit and resist loads through axial compression and bending. Properties like stress, deflection and strength depend on factors like grain direction, load type and material properties. Timber combines well with other materials like steel and concrete in composite structures.

Trusses

TRUSS IS A BRIEF TOPIC TO READ BUT I AM TRY TO THE SOME IMPORTANT TERMS TO MENTIONS IN THIS PRESENTATION

Japanese Architecture

The document discusses the architecture of Japan's Kansai region across different historical periods. It notes that the oldest existing buildings in Japan are from the Asuka period in the 7th century and were made of wood. Architecture evolved during the Heian period with the introduction of ceramic tile roofs and wood flooring. A notable example from this era is the Phoenix Hall built in 1053 near Kyoto. Architecture further developed during the Kamakura period through influences from Korea and China, featuring wooden construction and tile roofs. After World War 2, modern steel and concrete buildings replaced traditional wooden structures as Japan rebuilt its cities.

Roofs

The document discusses different types of roofs, their components, and considerations for design. It describes roofs as the uppermost part of a building that protects it from weather using structural elements and coverings. The main types are pitched, flat, and curved roofs. Pitched roofs are suitable for heavy rainfall areas and have simple shapes, while flat roofs can be used on buildings of any size or shape, especially in hot and dry regions. Key elements of roofs include the pitch, coverings, rafters, purlins, ridges, and eaves. Single roofs like lean-to and couple roofs have limited spans, while double roofs using purlins can support longer spans.

Rigid frame systems

The document discusses rigid frame systems used in high-rise buildings. It provides a history of rigid frames, an introduction to what they are, and examples of their applications. It describes the material properties and connections used. It discusses considerations for rigid frame design like behavior under lateral loads. It notes advantages like architectural freedom but also disadvantages like increased drift. It concludes with a case study on using hybrid rigid/semi-rigid frames to improve seismic performance.

Steel Structure Design (Study Report).pptx

This document provides an overview of steel structure design. It discusses the types of steel structures like truss, frame, grid and arch structures. It describes the methodology of steel design using Allowable Strength Design and Load and Resistance Factor Design. It discusses the mechanical properties of steel, concepts of limit state design for beam columns, and connections. It also provides details on the design of beams, including classifications of beams and the main considerations in beam design.

Design of singly reinforced sections Using First Principales - تصميم القطاعات...

مُلخصات طالب فيما يخص مادة تصميم المنشآت الخرسانية المسلحه

Steel sections-Building Construction

This document discusses different types of structural sections used in construction, including steel trusses, tubular sections, and angle sections. It provides an overview of trusses, describing their main components and different types of truss configurations. Tubular sections or hollow structural sections are discussed next, outlining their manufacturing process and common uses in buildings, bridges, and other structures. Finally, the document examines angle sections, defining their types, sizes, fixing details, and applications for reinforcement, support, framework, and decoration.

Steel Roof Truss

This document summarizes steel roof trusses. Most building roofs can be framed with prefabricated light-gauge steel trusses, which offer a high-strength, lightweight roof system that can be installed quickly. Steel trusses are manufactured from C-shaped galvanized steel and are stronger than wood trusses. They are constructed by connecting chord and web members made of steel into triangular shapes, then bolting or welding them together on the ground before installing the completed truss on the roof. All steel roofing has a protective metallic coating to prevent rusting.

Basic structure

Basic beam column structure construction and examples and lastly shell structure in short.

Rafiq azam buildings.Richerd Mier, Le Corbusier, Tadao Ando residences.

Bangladesh Liberation War museum

Sydney opera house

Unit 7 interpenetrations of solids

1. When two solids intersect, their surfaces meet along a curve called the curve of intersection. This curve is common to both solids.

2. Curves of intersection show the exact maximum surface contact between two solids, which is important for making strong, leak-proof joints when solids are joined together.

3. The document provides examples of determining the curve of intersection for various solids penetrating each other, such as cylinders, prisms, and cones. The method involves drawing three views and transferring points of intersection between views.

L16_17_Shell structures.pdf

Shell structures are thin curved structures that are efficient at using materials. They can be found in nature and are used for industrial and architectural structures like silos, tanks, and roofs. Shells are difficult to analyze due to their complex behavior under loads. Different types of shells include elliptic paraboloids, hyperbolic paraboloids, and circular cylinders. Buckling is an instability issue for shells where they change shape under load. Several methods are used to analyze shells including finite element analysis, membrane theory, and bending theory equations.

FLITCHED BEAMS

This document discusses flitched beams, which are composite beams made of wood beams sandwiched around a steel plate and held together with bolts. It defines beams and types of beams, then explains what composite beams and flitched beams are. It describes the design principle of flitched beams, which combines the properties of wood and steel to provide greater strength than either material alone. Applications of flitched beams include construction of houses and decks where they are stronger than wood but lighter than steel. However, engineered wood has replaced flitched beams due to lower costs and easier installation.

Support reactions

Types of Beam

Types of Loads acting on beam

Types of Supports

Instrument used for finding “Support Reactions”

How to find “Support Reactions”

SURFACE ACTIVE STRUCTURES(structure systems)

Basic and simplified introduction of Shell and Dome structures for Architects and Structural Engineer and students of related streams.

ARCHES AND DOMES

The document discusses different types of arches and domes and their construction techniques. It provides details on the key components of arches like voussoirs, keystone, intrados, etc. It describes various arch forms including flat arch, corbelled arch, triangular arch, semicircular arch, bullseye arch, Islamic arch, segmental arch, and pointed Gothic arch. It also explains dome structures and provides examples of different dome styles such as onion domes, geodesic domes, corbel domes, parabolic domes, saucer domes, and umbrella domes. The document aims to educate about the forms and building of common arch and dome structures.

Mega prefab post tension catalog

Mega Prefab is a complete service provider of structural precast and post-tensioned concrete. We are involved in all the phases of the project. We will design, manufacture, deliver and install our products. With more than 16 years experience in the business, we have optimized our structural elements to be efficient, safe and low cost.

Types of beam & types of supports

This document discusses different types of beams and supports used in engineering mechanics. It describes four types of supports - fixed, simple, roller, and hinged - based on how they restrict the movement of beams. It also outlines six types of beams defined by their support conditions: fixed, cantilever, simply supported, overhanging, continuous, and combinations of these. Finally, it categorizes loads as point, uniformly distributed, or uniformly varying based on how forces are applied along the beam.

What's hot (20)

Lecture 07: Islamic Architecture in India_Tughlaq Dynasty

Lecture 07: Islamic Architecture in India_Tughlaq Dynasty

Design of singly reinforced sections Using First Principales - تصميم القطاعات...

Design of singly reinforced sections Using First Principales - تصميم القطاعات...

Similar to mechanics of structure(CE3G)- simple stress & strain.ppt

Stess strain basic concept

This document provides an overview of stress, strain, and modulus of elasticity concepts in mechanical engineering. It defines stress as force per unit area, strain as the deformation per original length. Hooke's law states deformation is directly proportional to force. The modulus of elasticity E is the constant of proportionality between stress and strain. A stress-strain diagram is presented showing the elastic region, yield point, plastic region, strain hardening, and necking behavior. Shear stress and modulus of rigidity G are also defined. Design considerations like factor of safety are discussed for selecting allowable loads below ultimate strengths.

Stress strain sm (1) (1)

- Stress is defined as force per unit area and strain is defined as deformation per original length. Direct stress and strain occur when a direct tensile or compressive force is applied.

- A stress-strain diagram shows the relationship between stress and strain. It initially increases linearly as stress is proportional to strain. Beyond the proportional limit, plastic deformation occurs.

- Shear stress is defined as force per unit area of a cross section and acts sideways on a material. Shear stress has a maximum limit called the ultimate shear stress. Tensile stress also has a maximum limit known as the ultimate tensile stress, which is reached if a material is stretched until it breaks.

ASE301 19355 11012021 LECTURE 1.pdf

- Stress is the internal resisting force per unit area caused by external forces. It is measured in units of pressure like Pa or MPa. Strain is the deformation per original length and is dimensionless.

- Hooke's law states that deformation is directly proportional to applied force. The constant of proportionality is the modulus of elasticity E. A graph of stress vs strain results in a straight line with slope E.

- Materials have a maximum stress level before breaking called the ultimate tensile stress. Shear stress is caused by sideways forces and measured as force per unit area. Shear strain is the ratio of deformation to original height for small angles. The modulus of rigidity G defines the relationship between shear

stress strain sm

Mohamad Redhwan Abd Aziz is a lecturer at the DEAN CENTER OF HND STUDIES who teaches the subject of Solid Mechanics (BME 2023). The 3 credit hour course involves 2 hours of lectures and 2 hours of labs/tutorials each week. Student assessment includes quizzes, assignments, tests, lab reports, and a final exam. The course objectives are to understand stress, strain, and forces in solid bodies through various principles and experiments. Topic areas covered include stress and strain, elasticity, shear, torsion, bending, deflection, and more. References for the course are provided.

Stress

This document discusses different types of forces that can act on materials and how materials respond. It defines elastic and inelastic bodies, Hooke's law, stress and strain, Young's modulus, shear modulus, and bulk modulus. Hooke's law states that the force needed to deform a spring is proportional to the distance of deformation. Stress is defined as force per unit area. Strain is the ratio of deformation to original length. Young's modulus is the ratio of stress to strain and indicates a material's stiffness. Shear and bulk moduli also describe a material's resistance to different types of deformation.

1. simple stress and strains

Ekeeda is an online portal which creates and provides exclusive content for all branches engineering.To have more updates you can goto www.ekeeda.com..or you can contact on 8433429809...

Ms chapter 5

The document discusses the behavior of materials under stress and strain. It defines stress as the internal resistance of a material to external loads, and strain as the deformation or change in shape of a material under stress. The key types of stress are tensile, compressive, and shear stress. Hooke's law states that stress is proportional to strain within the material's elastic limit, after which plastic deformation occurs. The elastic modulus, shear modulus, and bulk modulus describe a material's response to different types of stress.

Som (lecture 2)

The document discusses stresses and strains, including:

1) It defines stress-strain diagrams, which plot stress versus strain, and describes the different regions including the elastic region, yield point, plastic region, and fracture point.

2) It explains concepts such as Hooke's law, elastic limit, yield strength, tensile strength, and strain hardening.

3) It discusses modulus of elasticity (Young's modulus), which is a measure of a material's stiffness, and Poisson's ratio, which relates lateral and linear strains.

Strength of Materials _Simple Strees and Stains _Unit-1.pptx

This document provides an overview of simple stresses and strains. It begins with prerequisites and contents, then defines stress and strain, describing normal and combined stresses like tensile, compressive, shear and torsional stresses. It discusses stress-strain diagrams for ductile materials like mild steel, showing regions like proportional limit, elastic limit, yielding points, ultimate stress and breaking point. It also covers Poisson's ratio, composite materials, thermal stresses and elastic constants. Measurement units and concepts like nominal vs true stress-strain curves, ductility measures, and factor of safety are summarized.

Som complete unit 01 notes

This document provides an overview of strength of materials and introduces key concepts. It discusses stress and strain, ductile and brittle materials, and stress-strain diagrams. Stress is defined as the internal resisting force per unit area acting on a material. Strain is the ratio of change in dimension to the original dimension when a body is subjected to external force. Ductile materials show deformation under stress, while brittle materials do not. The stress-strain diagram shows the relationship between stress and strain for ductile and brittle materials.

Aircraft materials lecture 3

This document discusses stress-strain curves and various material testing methods. It contains the following key points:

1. Creep testing involves applying a constant load to a material sample at high temperature and measuring deformation over time to evaluate materials performance. Fatigue testing subjects samples to repeated stresses to determine fatigue strength.

2. Stress-strain curves relate the stress and strain experienced by materials. They contain useful data like proportional limit, elastic limit, yield point, ultimate strength, and ductile vs. brittle fracture behavior.

3. True stress-strain diagrams account for changes in cross-sectional area during testing, while engineering stress-strain curves do not. Both are commonly used in design as long as strains remain

Aircraft materials lecture 3

This document discusses stress-strain curves and various material testing methods. It contains the following key points:

1. Creep testing involves applying a constant load to a material sample at high temperature and measuring deformation over time to evaluate materials performance. Fatigue testing subjects samples to repeated stresses to determine fatigue strength.

2. Stress-strain curves relate the stress and strain experienced by materials. They contain useful data like proportional limit, elastic limit, yield point, ultimate strength, and ductile vs. brittle fracture behavior.

3. True stress-strain curves account for changes in cross-sectional area during testing, providing a more accurate representation of material behavior, though engineering stress-strain curves are sufficient for most design

Introduction to engineering basics

This document discusses key concepts in strength of materials and engineering basics. It defines stress as the force per unit area on a material, and strain as the deformation or change in shape of a material under stress. The document outlines different types of stresses like tensile, compressive, and shear stress and the corresponding strains. It also discusses stress-strain curves and elastic properties like Young's modulus and Poisson's ratio. Finally, it covers topics like types of beams, loads, mechanical properties and more.

Introduction to engineering basics

This document discusses key concepts in strength of materials and engineering basics. It defines stress as the force per unit area on a material, and strain as the deformation or change in shape of a material under stress. The document outlines different types of stresses like tensile, compressive, and shear stress and the corresponding strains. It also discusses stress-strain curves and elastic properties like Young's modulus and Poisson's ratio. Finally, it covers types of beams, loads, and mechanical properties of materials.

9._Mechanical_Properties_of_Solids_1.pptx

This document discusses the mechanical properties of solids, including elasticity, plasticity, stress, strain, elastic limit, Hooke's law, modulus of elasticity, and stress-strain curves. It defines key terms and concepts related to how solids deform under force. Examples are given of how understanding mechanical properties informs applications like designing ropes for cranes and bridges to withstand loads within safe elastic limits. The maximum possible height of mountains is also calculated based on the shear modulus of typical rock.

Shear stress strain curve & modulus of rigidity (10.01.03.039)

This presentation introduces the topic of shear stress-strain curves and modulus of rigidity. It is presented by Afsana Ishrat Khan, a 4th year civil engineering student at an unknown university. The presentation was for a pre-stressed concrete laboratory course taught by Sabreena Nasrin Madam and Munshi Galib Muktadir Sir. The presentation defines shear stress and shear strain, describes typical shear stress-strain curves for different materials, and explains modulus of rigidity as the ratio of shear stress to shear strain.

Physics (1)

1. Hooke's law states that the stress and strain of a material are proportional for small deformations.

2. Young's modulus is a measure of the stiffness of a material and is defined as the ratio of tensile or compressive stress to longitudinal strain.

3. Shear modulus is defined as the ratio of shearing stress to shearing strain and measures a material's resistance to deformation via shear forces.

Som ppt

1. When a force is applied to a body, it causes the body to deform or change shape. This deformation is called strain. Direct stress is calculated as the applied force divided by the cross-sectional area.

2. Materials deform both elastically and plastically when stressed. Elastic deformation is reversible but plastic deformation causes a permanent change in shape. Hooke's law describes the linear elastic behavior of many materials, where stress is directly proportional to strain up to the elastic limit.

3. Thermal expansion and contraction can induce stress in materials as temperature changes unless deformation is unconstrained. The total strain is the sum of strain due to stress and strain due to temperature changes.

TE-3113-1.pdf

This document discusses mechanics of fibrous structures and materials. It begins with listing references used for the lectures. It then defines mechanics of materials as dealing with how solid bodies behave under various types of loading. The main goals are to determine stresses, strains, and displacements in structures due to loads.

It discusses the importance of understanding mechanics of materials, as the mechanical behavior of materials is essential for safe design of structures like buildings and machines. For textiles specifically, the mechanical behavior is important for processing and end product performance.

The document then covers fundamental concepts like stress, strain, tensile and compressive stresses and strains. It discusses analyzing material behavior through tensile testing and plotting stress-strain curves, which provide

Ch2_Mechanical Properties of Materials.pdf

Ch.2 in physics course for architecture students in faculty of fine arts in sustainable architecture and urban design program

Similar to mechanics of structure(CE3G)- simple stress & strain.ppt (20)

Strength of Materials _Simple Strees and Stains _Unit-1.pptx

Strength of Materials _Simple Strees and Stains _Unit-1.pptx

Shear stress strain curve & modulus of rigidity (10.01.03.039)

Shear stress strain curve & modulus of rigidity (10.01.03.039)

Recently uploaded

Understanding Inductive Bias in Machine Learning

This presentation explores the concept of inductive bias in machine learning. It explains how algorithms come with built-in assumptions and preferences that guide the learning process. You'll learn about the different types of inductive bias and how they can impact the performance and generalizability of machine learning models.

The presentation also covers the positive and negative aspects of inductive bias, along with strategies for mitigating potential drawbacks. We'll explore examples of how bias manifests in algorithms like neural networks and decision trees.

By understanding inductive bias, you can gain valuable insights into how machine learning models work and make informed decisions when building and deploying them.

A review on techniques and modelling methodologies used for checking electrom...

The proper function of the integrated circuit (IC) in an inhibiting electromagnetic environment has always been a serious concern throughout the decades of revolution in the world of electronics, from disjunct devices to today’s integrated circuit technology, where billions of transistors are combined on a single chip. The automotive industry and smart vehicles in particular, are confronting design issues such as being prone to electromagnetic interference (EMI). Electronic control devices calculate incorrect outputs because of EMI and sensors give misleading values which can prove fatal in case of automotives. In this paper, the authors have non exhaustively tried to review research work concerned with the investigation of EMI in ICs and prediction of this EMI using various modelling methodologies and measurement setups.

2008 BUILDING CONSTRUCTION Illustrated - Ching Chapter 02 The Building.pdf

2008 BUILDING CONSTRUCTION Illustrated - Ching Chapter 02 The Building

ISPM 15 Heat Treated Wood Stamps and why your shipping must have one

For International shipping and maritime laws all wood must contain the ISPM 15 Stamp. Here is how and why.

Casting-Defect-inSlab continuous casting.pdf

Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting. Casting-Defect-inSlab continuous casting

Unit-III-ELECTROCHEMICAL STORAGE DEVICES.ppt

Batteries -Introduction – Types of Batteries – discharging and charging of battery - characteristics of battery –battery rating- various tests on battery- – Primary battery: silver button cell- Secondary battery :Ni-Cd battery-modern battery: lithium ion battery-maintenance of batteries-choices of batteries for electric vehicle applications.

Fuel Cells: Introduction- importance and classification of fuel cells - description, principle, components, applications of fuel cells: H2-O2 fuel cell, alkaline fuel cell, molten carbonate fuel cell and direct methanol fuel cells.

官方认证美国密歇根州立大学毕业证学位证书原版一模一样

原版一模一样【微信:741003700 】【美国密歇根州立大学毕业证学位证书】【微信:741003700 】学位证,留信认证(真实可查,永久存档)offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原海外各大学 Bachelor Diploma degree, Master Degree Diploma

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微741003700

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

5214-1693458878915-Unit 6 2023 to 2024 academic year assignment (AutoRecovere...

Bigdata of technology

CHINA’S GEO-ECONOMIC OUTREACH IN CENTRAL ASIAN COUNTRIES AND FUTURE PROSPECT

The rivalry between prominent international actors for dominance over Central Asia's hydrocarbon

reserves and the ancient silk trade route, along with China's diplomatic endeavours in the area, has been

referred to as the "New Great Game." This research centres on the power struggle, considering

geopolitical, geostrategic, and geoeconomic variables. Topics including trade, political hegemony, oil

politics, and conventional and nontraditional security are all explored and explained by the researcher.

Using Mackinder's Heartland, Spykman Rimland, and Hegemonic Stability theories, examines China's role

in Central Asia. This study adheres to the empirical epistemological method and has taken care of

objectivity. This study analyze primary and secondary research documents critically to elaborate role of

china’s geo economic outreach in central Asian countries and its future prospect. China is thriving in trade,

pipeline politics, and winning states, according to this study, thanks to important instruments like the

Shanghai Cooperation Organisation and the Belt and Road Economic Initiative. According to this study,

China is seeing significant success in commerce, pipeline politics, and gaining influence on other

governments. This success may be attributed to the effective utilisation of key tools such as the Shanghai

Cooperation Organisation and the Belt and Road Economic Initiative.

Electric vehicle and photovoltaic advanced roles in enhancing the financial p...

Climate change's impact on the planet forced the United Nations and governments to promote green energies and electric transportation. The deployments of photovoltaic (PV) and electric vehicle (EV) systems gained stronger momentum due to their numerous advantages over fossil fuel types. The advantages go beyond sustainability to reach financial support and stability. The work in this paper introduces the hybrid system between PV and EV to support industrial and commercial plants. This paper covers the theoretical framework of the proposed hybrid system including the required equation to complete the cost analysis when PV and EV are present. In addition, the proposed design diagram which sets the priorities and requirements of the system is presented. The proposed approach allows setup to advance their power stability, especially during power outages. The presented information supports researchers and plant owners to complete the necessary analysis while promoting the deployment of clean energy. The result of a case study that represents a dairy milk farmer supports the theoretical works and highlights its advanced benefits to existing plants. The short return on investment of the proposed approach supports the paper's novelty approach for the sustainable electrical system. In addition, the proposed system allows for an isolated power setup without the need for a transmission line which enhances the safety of the electrical network

Harnessing WebAssembly for Real-time Stateless Streaming Pipelines

Traditionally, dealing with real-time data pipelines has involved significant overhead, even for straightforward tasks like data transformation or masking. However, in this talk, we’ll venture into the dynamic realm of WebAssembly (WASM) and discover how it can revolutionize the creation of stateless streaming pipelines within a Kafka (Redpanda) broker. These pipelines are adept at managing low-latency, high-data-volume scenarios.

The Python for beginners. This is an advance computer language.

Python language is very important language at this time. we can easily understand this language by these notes.

22CYT12-Unit-V-E Waste and its Management.ppt

Introduction- e - waste – definition - sources of e-waste– hazardous substances in e-waste - effects of e-waste on environment and human health- need for e-waste management– e-waste handling rules - waste minimization techniques for managing e-waste – recycling of e-waste - disposal treatment methods of e- waste – mechanism of extraction of precious metal from leaching solution-global Scenario of E-waste – E-waste in India- case studies.

Recently uploaded (20)

A review on techniques and modelling methodologies used for checking electrom...

A review on techniques and modelling methodologies used for checking electrom...

2008 BUILDING CONSTRUCTION Illustrated - Ching Chapter 02 The Building.pdf

2008 BUILDING CONSTRUCTION Illustrated - Ching Chapter 02 The Building.pdf

ISPM 15 Heat Treated Wood Stamps and why your shipping must have one

ISPM 15 Heat Treated Wood Stamps and why your shipping must have one

5214-1693458878915-Unit 6 2023 to 2024 academic year assignment (AutoRecovere...

5214-1693458878915-Unit 6 2023 to 2024 academic year assignment (AutoRecovere...

Generative AI leverages algorithms to create various forms of content

Generative AI leverages algorithms to create various forms of content

CHINA’S GEO-ECONOMIC OUTREACH IN CENTRAL ASIAN COUNTRIES AND FUTURE PROSPECT

CHINA’S GEO-ECONOMIC OUTREACH IN CENTRAL ASIAN COUNTRIES AND FUTURE PROSPECT

Electric vehicle and photovoltaic advanced roles in enhancing the financial p...

Electric vehicle and photovoltaic advanced roles in enhancing the financial p...

Harnessing WebAssembly for Real-time Stateless Streaming Pipelines

Harnessing WebAssembly for Real-time Stateless Streaming Pipelines

The Python for beginners. This is an advance computer language.

The Python for beginners. This is an advance computer language.

basic-wireline-operations-course-mahmoud-f-radwan.pdf

basic-wireline-operations-course-mahmoud-f-radwan.pdf

BPV-GUI-01-Guide-for-ASME-Review-Teams-(General)-10-10-2023.pdf

BPV-GUI-01-Guide-for-ASME-Review-Teams-(General)-10-10-2023.pdf

mechanics of structure(CE3G)- simple stress & strain.ppt

- 1. TOPICS • Topic cover – Stress and strain • Introduction to stress and strain, stress strain diagram • Elasticity and plasticity and Hooke’s law • Shear Stress and Shear strain • Load and stress limit • Axial force and deflection of body – Torsion • Introduction, round bar torsion, non-uniform torsion. • Relation between Young’s Modulus E, and G • Power transmission on round bar Visit for more Learning Resources

- 2. Stress and strain DIRECT STRESS When a force is applied to an elastic body, the body deforms. The way in which the body deforms depends upon the type of force applied to it. Compression force makes the body shorter. A tensile force makes the body longer

- 3. A F Area Force Stress 2 / m N Tensile and compressive forces are called DIRECT FORCES Stress is the force per unit area upon which it acts. ….. Unit is Pascal (Pa) or Note: Most of engineering fields used kPa, MPa, GPa. ( Simbol – Sigma)

- 4. L x Strain DIRECT STRAIN , In each case, a force F produces a deformation x. In engineering, we usually change this force into stress and the deformation into strain and we define these as follows: Strain is the deformation per unit of the original length. The symbol Strain has no unit’s since it is a ratio of length to length. Most engineering materials do not stretch very mush before they become damages, so strain values are very small figures. It is quite normal to change small numbers in to the exponent for 10-6( micro strain). called EPSILON

- 5. MODULUS OF ELASTICITY (E) •Elastic materials always spring back into shape when released. They also obey HOOKE’s LAW. •This is the law of spring which states that deformation is directly proportional to the force. F/x = stiffness = kN/m •The stiffness is different for the different material and different sizes of the material. We may eliminate the size by using stress and strain instead of force and deformation: •If F and x is refer to the direct stress and strain , then A F L x L A x F Ax FL hence and

- 6. E Ax FL •The stiffness is now in terms of stress and strain only and this constant is called the MODULUS of ELASTICITY (E) • A graph of stress against strain will be straight line with gradient of E. The units of E are the same as the unit of stress. ULTIMATE TENSILE STRESS •If a material is stretched until it breaks, the tensile stress has reached the absolute limit and this stress level is called the ultimate tensile stress.

- 8. STRESS STRAIN DIAGRAM Elastic behaviour The curve is straight line trough out most of the region Stress is proportional with strain Material to be linearly elastic Proportional limit The upper limit to linear line The material still respond elastically The curve tend to bend and flatten out Elastic limit Upon reaching this point, if load is remove, the specimen still return to original shape

- 9. STRESS STRAIN DIAGRAM Yielding A Slight increase in stress above the elastic limit will result in breakdown of the material and cause it to deform permanently. This behaviour is called yielding The stress that cause = YIELD STRESS@YIELD POINT Plastic deformation Once yield point is reached, the specimen will elongate (Strain) without any increase in load Material in this state = perfectly plastic

- 10. STRESS STRAIN DIAGRAM • STRAIN HARDENING – When yielding has ended, further load applied, resulting in a curve that rises continuously – Become flat when reached ULTIMATE STRESS – The rise in the curve = STRAIN HARDENING – While specimen is elongating, its cross sectional will decrease – The decrease is fairly uniform • NECKING – At the ultimate stress, the cross sectional area begins its localised region of specimen – it is caused by slip planes formed within material – Actual strain produced by shear strain – As a result, “neck” tend to form – Smaller area can only carry lesser load, hence curve donward – Specimen break at FRACTURE STRESS

- 11. SHEAR STRESS •Shear force is a force applied sideways on the material (transversely loaded). When a pair of shears cut a material When a material is punched When a beam has a transverse load

- 12. Shear stress is the force per unit area carrying the load. This means the cross sectional area of the material being cut, the beam and pin. A F and symbol is called Tau •Shear stress, The sign convention for shear force and stress is based on how it shears the materials as shown below.

- 13. L x L x SHEAR STRAIN The force causes the material to deform as shown. The shear strain is defined as the ratio of the distance deformed to the height . Since this is a very small angle , we can say that : ( symbol called Gamma) Shear strain

- 14. •If we conduct an experiment and measure x for various values of F, we would find that if the material is elastic, it behave like spring and so long as we do not damage the material by using too big force, the graph of F and x is straight line as shown. MODULUS OF RIGIDITY (G) The gradient of the graph is constant so t cons x F tan and this is the spring stiffness of the block in N/m. •If we divide F by area A and x by the height L, the relationship is still a constant and we get

- 15. t con Ax FL x L x A F L x A F tan A F Where L x t con Ax FL x L x A F tan then •If we divide F by area A and x by the height L, the relationship is still a constant and we get This constant will have a special value for each elastic material and is called the Modulus of Rigidity (G). G

- 16. ULTIMATE SHEAR STRESS If a material is sheared beyond a certain limit and it becomes permanently distorted and does not spring all the way back to its original shape, the elastic limit has been exceeded. If the material stressed to the limit so that it parts into two, the ultimate limit has been reached. The ultimate shear stress has symbol and this value is used to calculate the force needed by shears and punches.

- 26. DOUBLE SHEAR Consider a pin joint with a support on both ends as shown. This is called CLEVIS and CLEVIS PIN By balance of force, the force in the two supports is F/2 each The area sheared is twice the cross section of the pin So it takes twice as much force to break the pin as for a case of single shear Double shear arrangements doubles the maximum force allowed in the pin

- 29. LOAD AND STRESS LIMIT DESIGN CONSIDERATION Will help engineers with their important task in Designing structural/machine that is SAFE and ECONOMICALLY perform for a specified function DETERMINATION OF ULTIMATE STRENGTH An important element to be considered by a designer is how the material that has been selected will behave under a load This is determined by performing specific test (e.g. Tensile test) ULTIMATE FORCE (PU)= The largest force that may be applied to the specimen is reached, and the specimen either breaks or begins to carry less load ULTIMATE NORMAL STRESS (U) = ULTIMATE FORCE(PU) /AREA

- 30. ALLOWABLE LOAD / ALLOWABLE STRESS Max load that a structural member/machine component will be allowed to carry under normal conditions of utilisation is considerably smaller than the ultimate load This smaller load = Allowable load / Working load / Design load Only a fraction of ultimate load capacity of the member is utilised when allowable load is applied The remaining portion of the load-carrying capacity of the member is kept in reserve to assure its safe performance The ratio of the ultimate load/allowable load is used to define FACTOR OF SAFETY FACTOR OF SAFETY = ULTIMATE LOAD/ALLOWABLE LOAD @ FACTOR OF SAFETY = ULTIMATE STRESS/ALLOWABLE STRESS

- 31. SELECTION OF F.S. 1. Variations that may occur in the properties of the member under considerations 2. The number of loading that may be expected during the life of the structural/machine 3. The type of loading that are planned for in the design, or that may occur in the future 4. The type of failure that may occur 5. Uncertainty due to the methods of analysis 6. Deterioration that may occur in the future because of poor maintenance / because of unpreventable natural causes 7. The importance of a given member to the integrity of the whole structure

- 32. WORKED EXAMPLE 8 0.6 m

- 33. SOLUTION

- 34. SOLUTION

- 35. SELF ASSESSMENT NO. 5

- 36. AXIAL FORCE & DEFLECTION OF BODY Deformations of members under axial loading If the resulting axial stress does not exceed the proportional limit of the material, Hooke’s Law may be applied Then deformation (x / ) can be written as AE FL E

- 37. WORKED EXAMPLE 9 0.4 m

- 38. WORKED EXAMPLE 9

- 39. WORKED EXAMPLE 9

- 40. SELF ASSESSMENT NO. 6 For more detail contact us