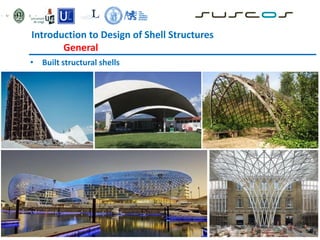

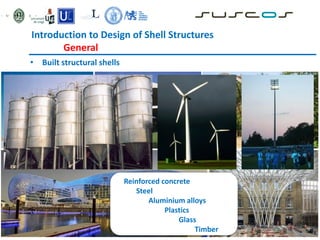

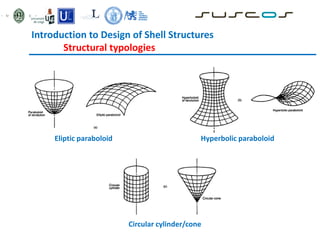

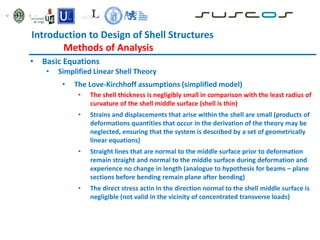

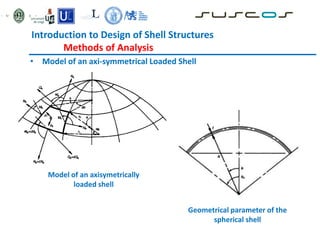

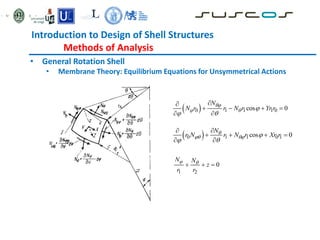

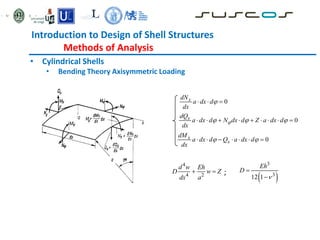

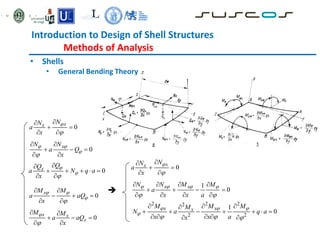

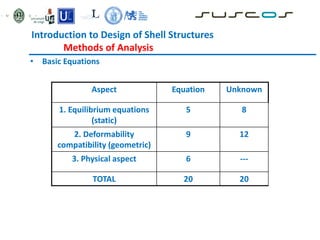

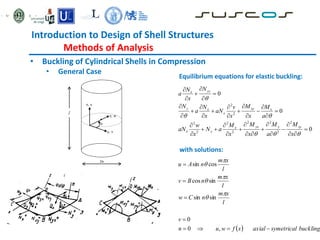

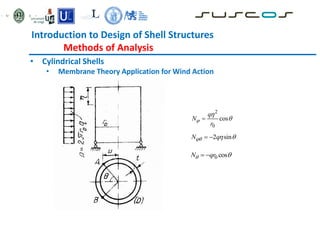

Shell structures are thin curved structures that are efficient at using materials. They can be found in nature and are used for industrial and architectural structures like silos, tanks, and roofs. Shells are difficult to analyze due to their complex behavior under loads. Different types of shells include elliptic paraboloids, hyperbolic paraboloids, and circular cylinders. Buckling is an instability issue for shells where they change shape under load. Several methods are used to analyze shells including finite element analysis, membrane theory, and bending theory equations.

![Introduction to Design of Shell Structures

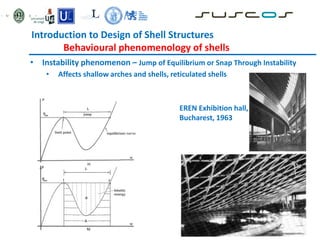

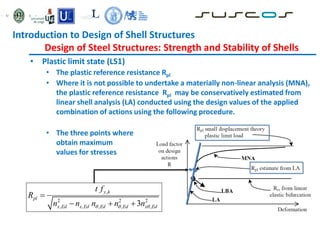

Behavioural phenomenology of shells

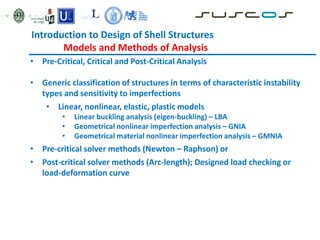

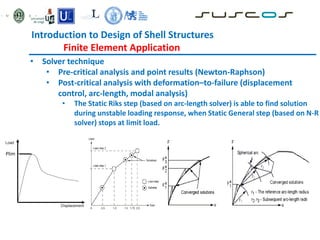

• Behavior of a given structure (slender!) can be controlled by design if

the three characteristic ranges of load-deformation curve are correctly

defined

• Pre-critical range

• Critical point (or range)

• Post-critical range

P

D

Pcr

Critical point

Post-critical

range

Pre-critical range

P(0, Pcr] Structural stability

P > Pcr Structural instability

elastic

Buckling: plastic

dynamic](https://image.slidesharecdn.com/l1617shellstructures-230804033536-216a9f66/85/L16_17_Shell-structures-pdf-20-320.jpg)

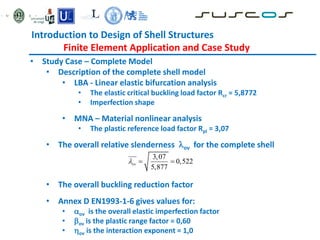

![Introduction to Design of Shell Structures

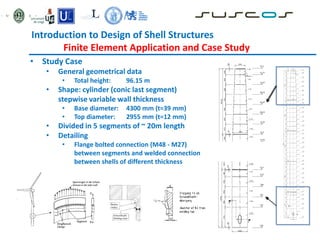

Finite Element Application and Case Study

• Study Case – Complete Model

• LA / MNA at reference load results

• Local plastic zones around

connecting flanges

• LBA results Rcr = 5,877

Bottom

section

Axial

force

[kN]

Shear

force

[kN]

Bending

moment

[kNm]

LA 4323 1260 80088

MNA 4323 1260 80088](https://image.slidesharecdn.com/l1617shellstructures-230804033536-216a9f66/85/L16_17_Shell-structures-pdf-122-320.jpg)

![Introduction to Design of Shell Structures

Finite Element Application and Case Study

• Study Case – Complete Model

• MNA Rpl = 3,07

• GMNA Rpl = 1,77

• GMNIA Rpl = 1,49

0

0.5

1

1.5

2

2.5

3

3.5

0 1 2 3 4 5 6

Displacement [m]

Load

factor

R

GMNA

MNA

GMNIA

Reactions

at

Axial

force

[kN]

Shear

force

[kN]

Bending

moment

[kNm]

R = 1 4323 1260 80088](https://image.slidesharecdn.com/l1617shellstructures-230804033536-216a9f66/85/L16_17_Shell-structures-pdf-123-320.jpg)

![Introduction to Design of Shell Structures

Finite Element Application and Case Study

• Study Case – Refined door opening segment

LBA results Rcr = 12.248

• Numerical model

Section

Axial force

[kN]

Shear force

[kN]

Bending moment

[kNm]

Upper section 4413 1231 73988

Bottom section 4413 1231 88514](https://image.slidesharecdn.com/l1617shellstructures-230804033536-216a9f66/85/L16_17_Shell-structures-pdf-125-320.jpg)

![Introduction to Design of Shell Structures

Finite Element Application and Case Study

• Study Case – Refined door opening segment

• LA Results

• GMNA Results

Bottom segment

0

0.5

1

1.5

2

2.5

3

0 50 100 150 200 250 300

Displacement [mm]

Load

factor

GMNA](https://image.slidesharecdn.com/l1617shellstructures-230804033536-216a9f66/85/L16_17_Shell-structures-pdf-126-320.jpg)

![Introduction to Design of Shell Structures

Finite Element Application and Case Study

• Study Case – Refined door opening segment

• Numerical model

Section Axial force

[kN]

Shear force

[kN]

Bending moment

[kNm]

Upper section 1586 409 13055

Bottom section 2015 666 23897

max 2

1 2150

0,46 1 0,1 0,46 1 0,1 0,514

119 13,14

20000

119

2150 13,14

0,541 1430 1,5 1102

w

eq w

c r

k

t

l r l

r t rt

N

q k q

m

• Transformation of typical wind pressure load distribution

• LA Rpl = (126/355)=2,82](https://image.slidesharecdn.com/l1617shellstructures-230804033536-216a9f66/85/L16_17_Shell-structures-pdf-127-320.jpg)

![• Study Case – Refined door opening segment

• LBA Results

Section Rcr

Without EWL 6,8006

With EWL 6,8003

• GMNIA results

• Imperfection afine first buckling mode

• Amplitude of imperfection 23mm and 17mm

corresponding to normal and high tolerance

Quality class kGMNIA

High (~17 mm) 1,79

Normal (~23 mm) 1,72

Relevant segment

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 0.002 0.004 0.006 0.008 0.01 0.012 0.014 0.016

Rotation [rad]

Load

factor

GMNIA normal

GMNIA high

kGMNIA

Introduction to Design of Shell Structures

Finite Element Application and Case Study](https://image.slidesharecdn.com/l1617shellstructures-230804033536-216a9f66/85/L16_17_Shell-structures-pdf-128-320.jpg)