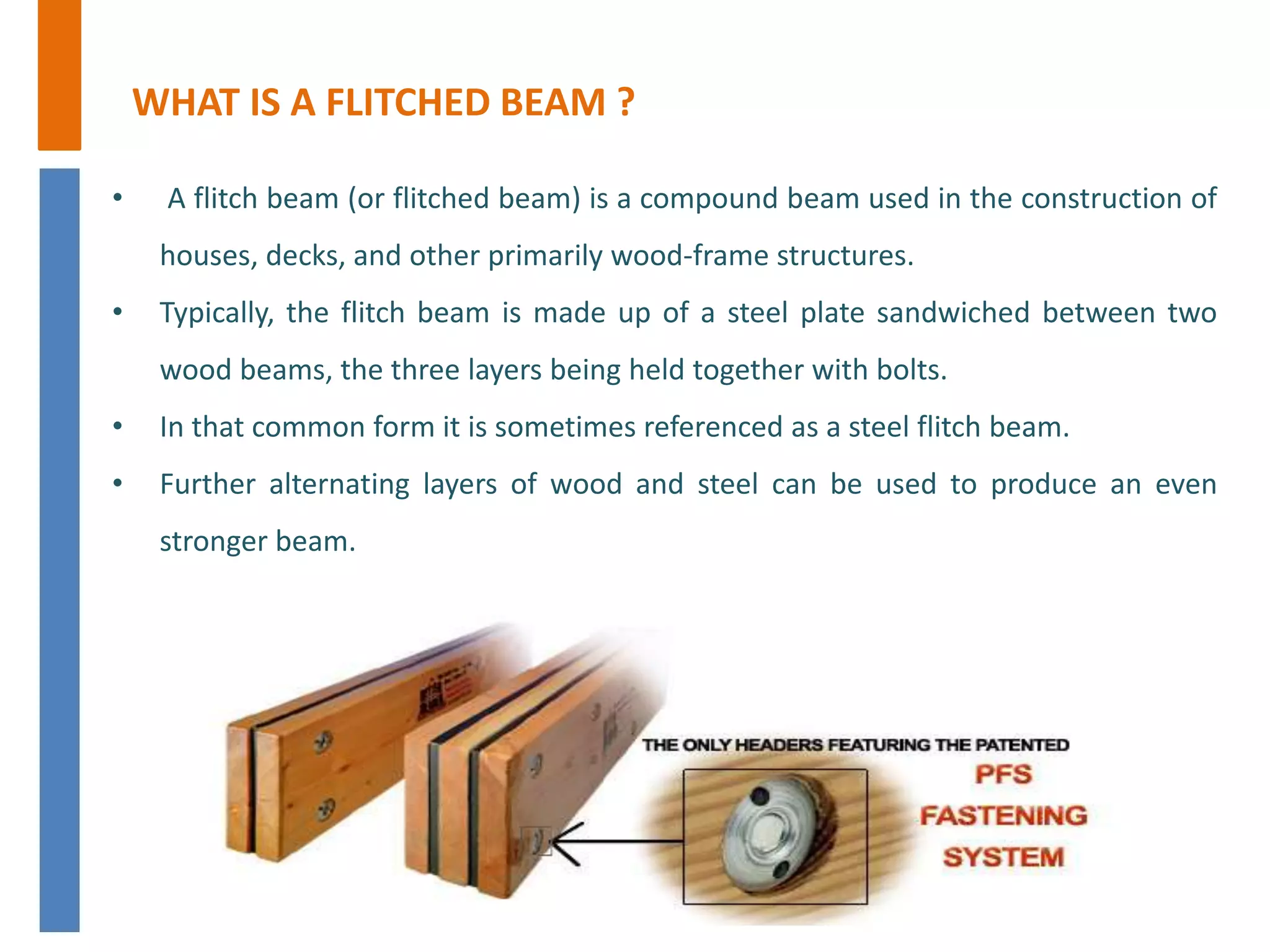

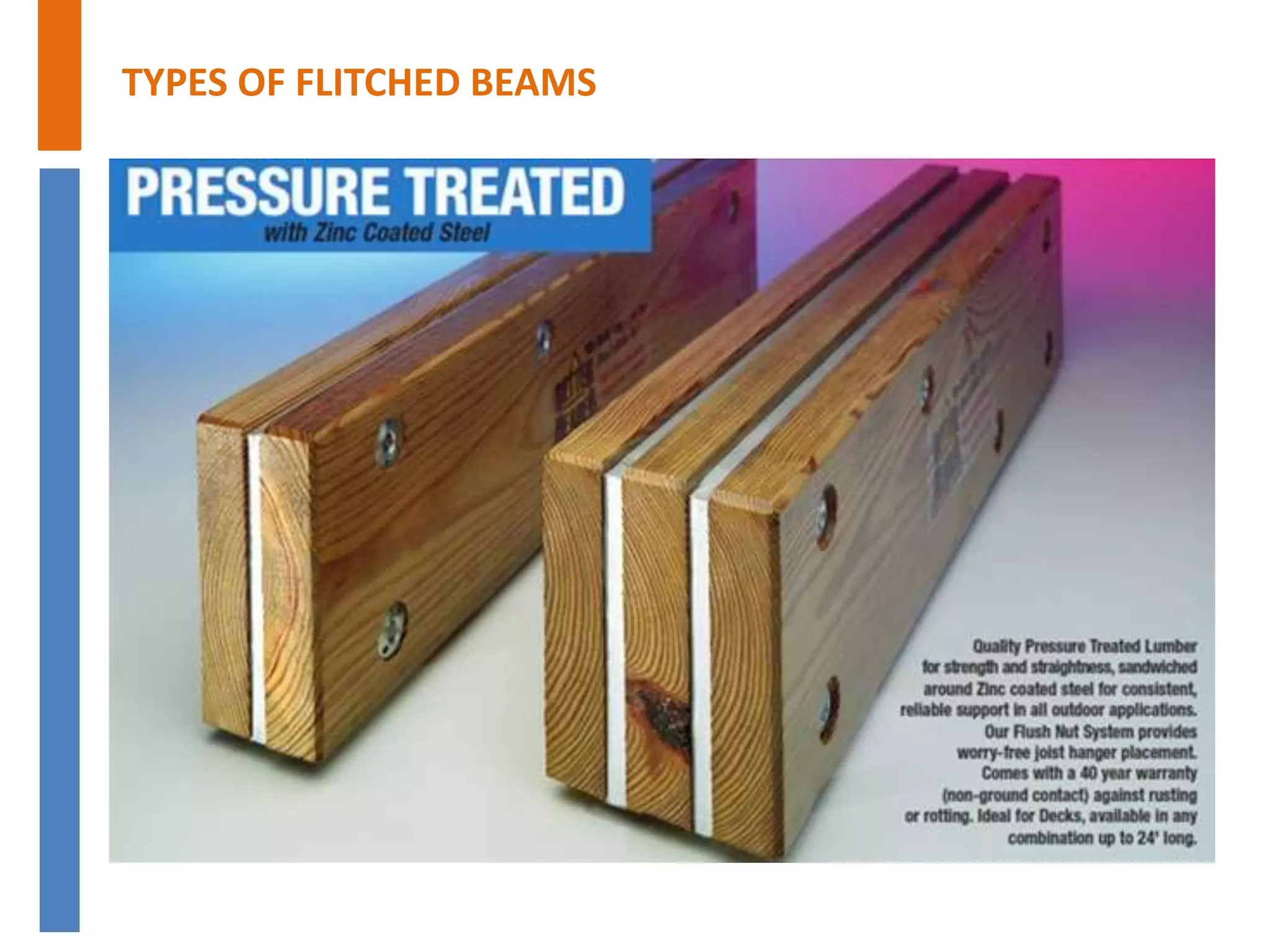

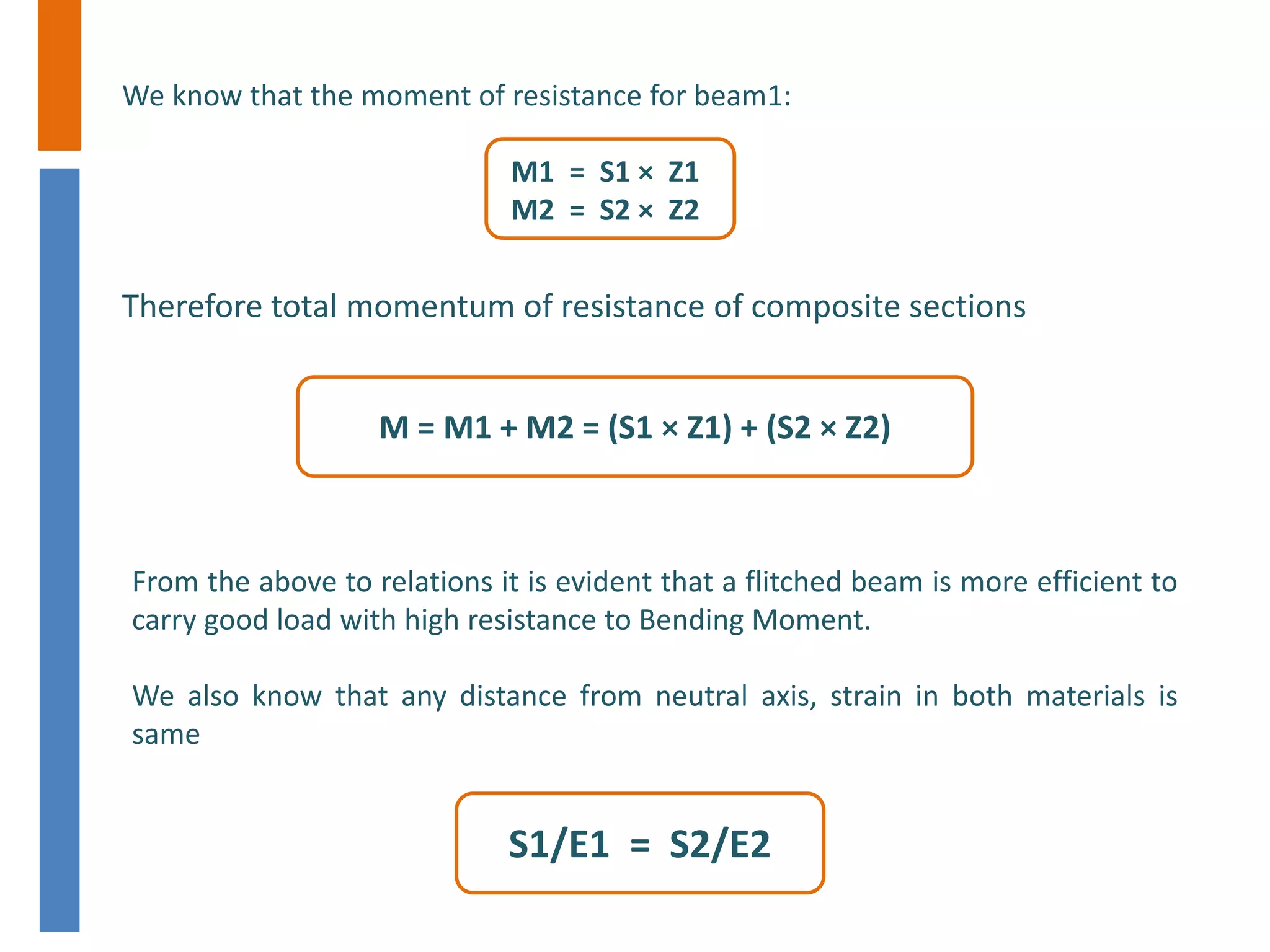

This document discusses flitched beams, which are composite beams made of wood beams sandwiched around a steel plate and held together with bolts. It defines beams and types of beams, then explains what composite beams and flitched beams are. It describes the design principle of flitched beams, which combines the properties of wood and steel to provide greater strength than either material alone. Applications of flitched beams include construction of houses and decks where they are stronger than wood but lighter than steel. However, engineered wood has replaced flitched beams due to lower costs and easier installation.