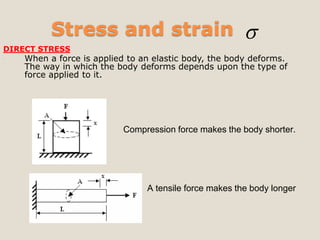

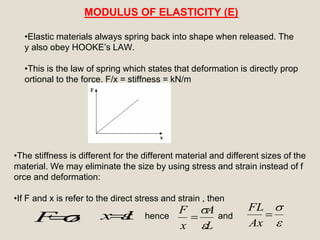

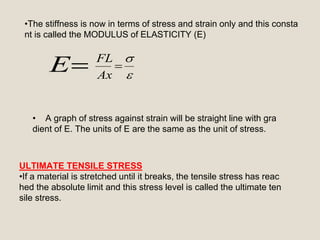

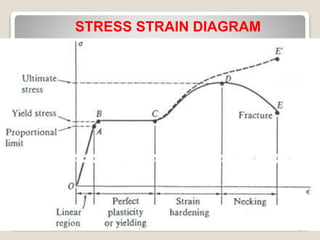

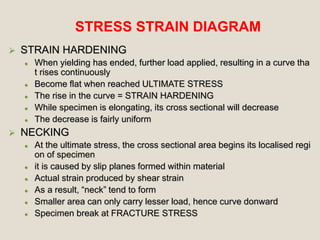

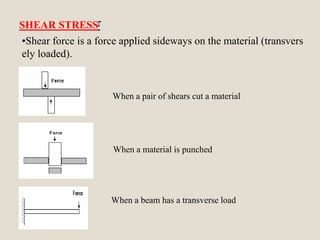

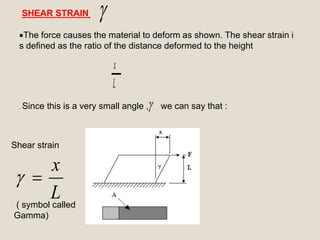

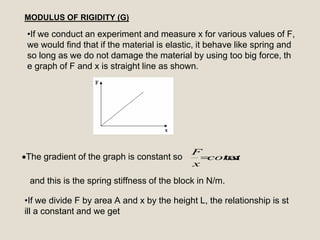

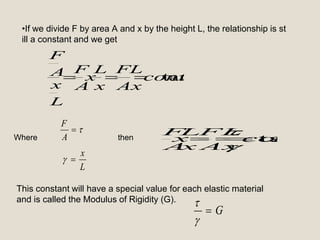

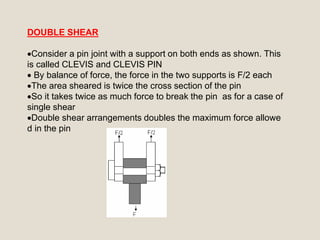

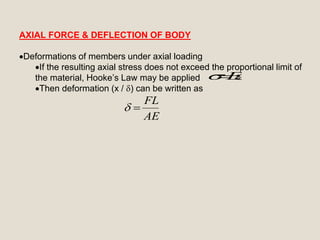

This document provides an overview of stress, strain, and modulus of elasticity concepts in mechanical engineering. It defines stress as force per unit area, strain as the deformation per original length. Hooke's law states deformation is directly proportional to force. The modulus of elasticity E is the constant of proportionality between stress and strain. A stress-strain diagram is presented showing the elastic region, yield point, plastic region, strain hardening, and necking behavior. Shear stress and modulus of rigidity G are also defined. Design considerations like factor of safety are discussed for selecting allowable loads below ultimate strengths.