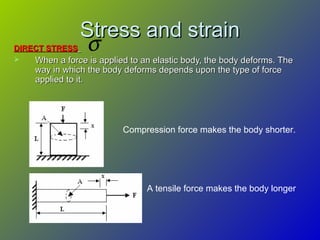

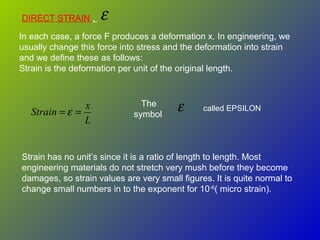

- Stress is defined as force per unit area and strain is defined as deformation per original length. Direct stress and strain occur when a direct tensile or compressive force is applied.

- A stress-strain diagram shows the relationship between stress and strain. It initially increases linearly as stress is proportional to strain. Beyond the proportional limit, plastic deformation occurs.

- Shear stress is defined as force per unit area of a cross section and acts sideways on a material. Shear stress has a maximum limit called the ultimate shear stress. Tensile stress also has a maximum limit known as the ultimate tensile stress, which is reached if a material is stretched until it breaks.