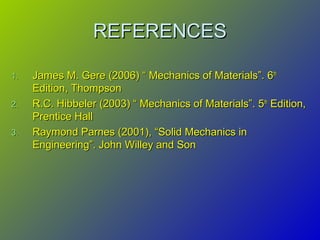

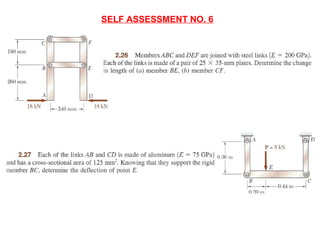

Mohamad Redhwan Abd Aziz is a lecturer at the DEAN CENTER OF HND STUDIES who teaches the subject of Solid Mechanics (BME 2023). The 3 credit hour course involves 2 hours of lectures and 2 hours of labs/tutorials each week. Student assessment includes quizzes, assignments, tests, lab reports, and a final exam. The course objectives are to understand stress, strain, and forces in solid bodies through various principles and experiments. Topic areas covered include stress and strain, elasticity, shear, torsion, bending, deflection, and more. References for the course are provided.