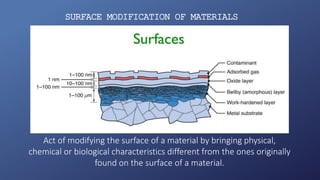

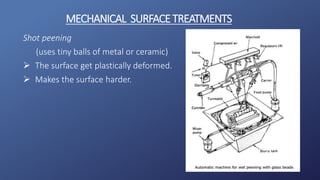

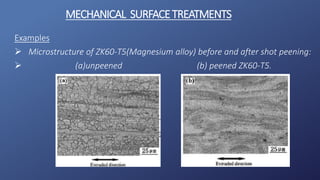

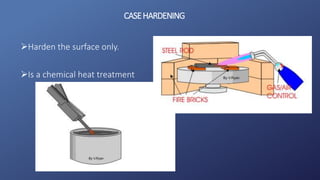

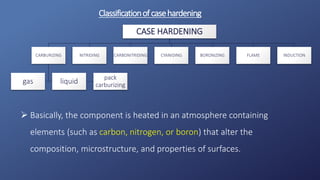

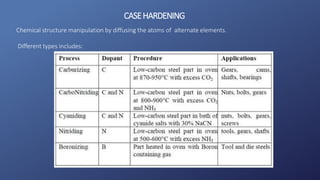

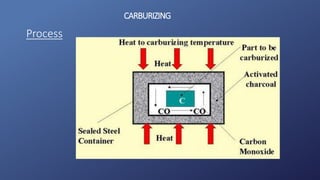

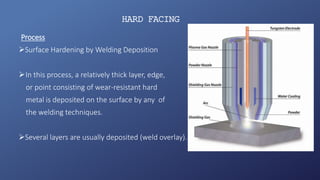

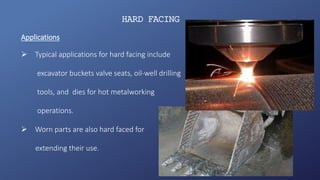

The document discusses various surface modification techniques for materials, including mechanical surface treatment, case hardening, and hardfacing, aimed at enhancing properties like hardness and durability. It details several specific methods such as shot peening, laser peening, and chemical treatments like carburizing and nitriding. Additionally, it covers applications, advantages, and precautions associated with these surface treatments to improve material performance.

![NITRIDING

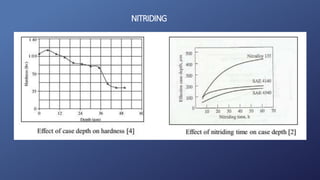

Nitrogen is diffused into the surface of the component being treated.

Nitriding Temperature: 500-600°C [2]](https://image.slidesharecdn.com/platingcasehardeninghardfacing-160207085027/85/Mechanical-Plating-Casehardening-Hardfacing-31-320.jpg)

![REFERENCES

1. Anon., Surface Treatment, Coating and

Cleaning,http://www.ielm.ust.hk/dfaculty/ajay/courses/ieem215/lecs/9_surfacetreatment.pdf,retrieved on

29.12.2012.

2. Kenneth G. Budinski and Michael K. Budinski., (2009) Engineering Materials: Properties and Selection, 9th

edition, Prentice Hall Publishers.

3. Anon., Heat Treatment Properties, http://www.tohokusteel.com/en/pages/kirin1.htm, retrieved on 29.12.2012.

4. Hiroshi Yamagatta – “Science and technology of materials” [pg 180 onwards].

5. Induction hardening - http://www.ustudy.in/node/4157

6. Mark davis – “Gear hardening goes green”

http://www.eldec.de/fileadmin/00_Dateien/PDF/Veroeffentlichungen/0909_GearSolutions.pdf](https://image.slidesharecdn.com/platingcasehardeninghardfacing-160207085027/85/Mechanical-Plating-Casehardening-Hardfacing-47-320.jpg)

![REFERENCES

7. Daewei heating machine co., ltd - http://www.dw-inductionheating.com/hardeninginduction-

heating-applications.html/hardening-induction-heating, retrieved on 29.12.2012

8. Volume 05 Surface Engineering - Cleaning, Finishing and Coating- by ASM

9. Effect of Shot Peening on Surface Characteristics and Fatigue Properties of T5-Treated ZK60 Alloy-

Wencai Liu 1, Jie Dong 1 ;*, Ping Zhang 2, Chunquan Zhai 1 ; 3 and Wenjiang Ding 1 ; 3 1 National

Engineering Research Center of Light Alloy Net Forming, School of Materials Science and

Engineering,

10. http://mechanicalplating.com/glass_be.htm]

11. H. Soyama and O. Takakuwa, Journal of Fluid Science and Technology, Vol. 6 (2011), pp. 510-521.](https://image.slidesharecdn.com/platingcasehardeninghardfacing-160207085027/85/Mechanical-Plating-Casehardening-Hardfacing-48-320.jpg)