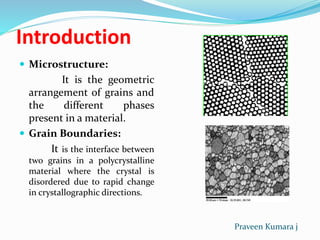

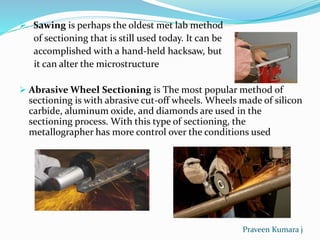

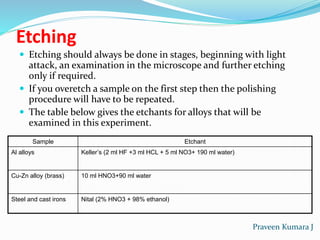

This document provides an overview of microstructural analysis and the specimen preparation process. Microstructural analysis is used for quality control, failure analysis, and research studies to understand the relationship between processing, structure, and properties of materials. The specimen preparation process includes sectioning, mounting, grinding, polishing, and etching samples to reveal the microstructure for analysis. Etching involves chemically attacking the surface to provide contrast between grains and grain boundaries under an optical microscope. Microstructural analysis provides information about the structure of materials.