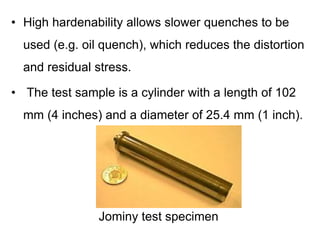

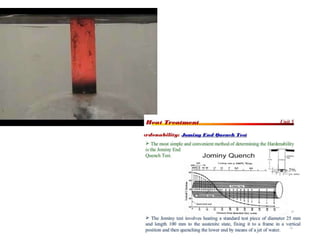

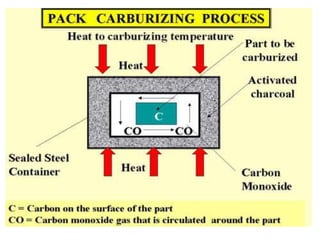

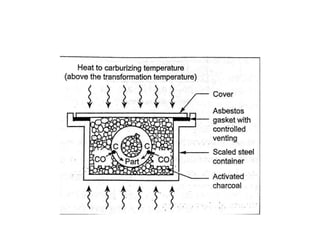

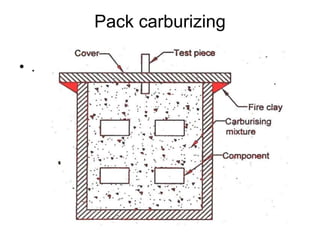

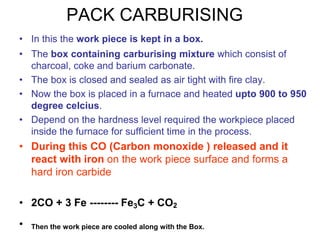

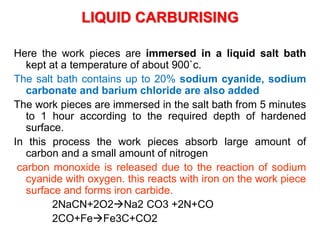

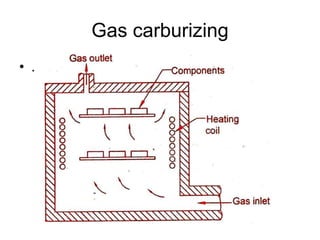

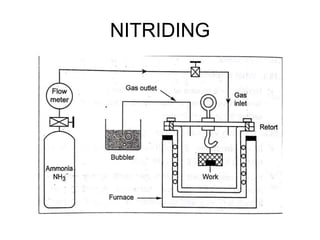

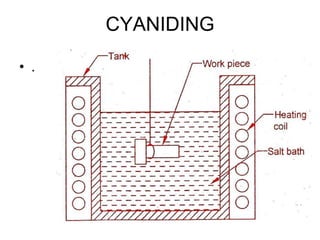

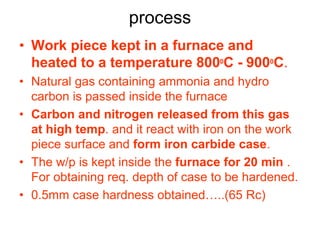

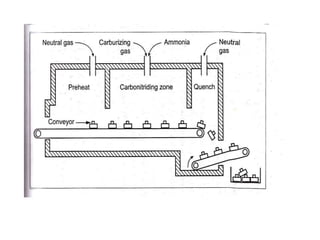

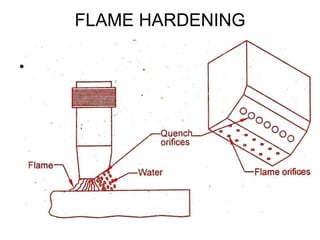

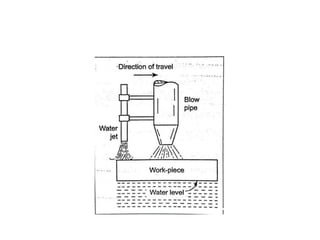

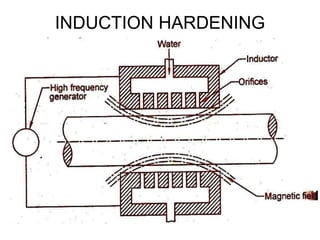

Hardenability refers to a steel's ability to transform to martensite and achieve hardness through quenching. The Jominy end quench test measures hardenability by water quenching one end of a cylindrical steel sample, then measuring hardness levels at intervals from the quenched end. Higher hardness indicates more martensite formation and better hardenability. Case hardening processes like carburizing add carbon to the surface of low-carbon steels to create a hard case while leaving the core tough. Common methods include pack, liquid, and gas carburizing, as well as cyaniding, nitriding, and carbonitriding. Flame and induction hardening also locally harden surfaces through rapid