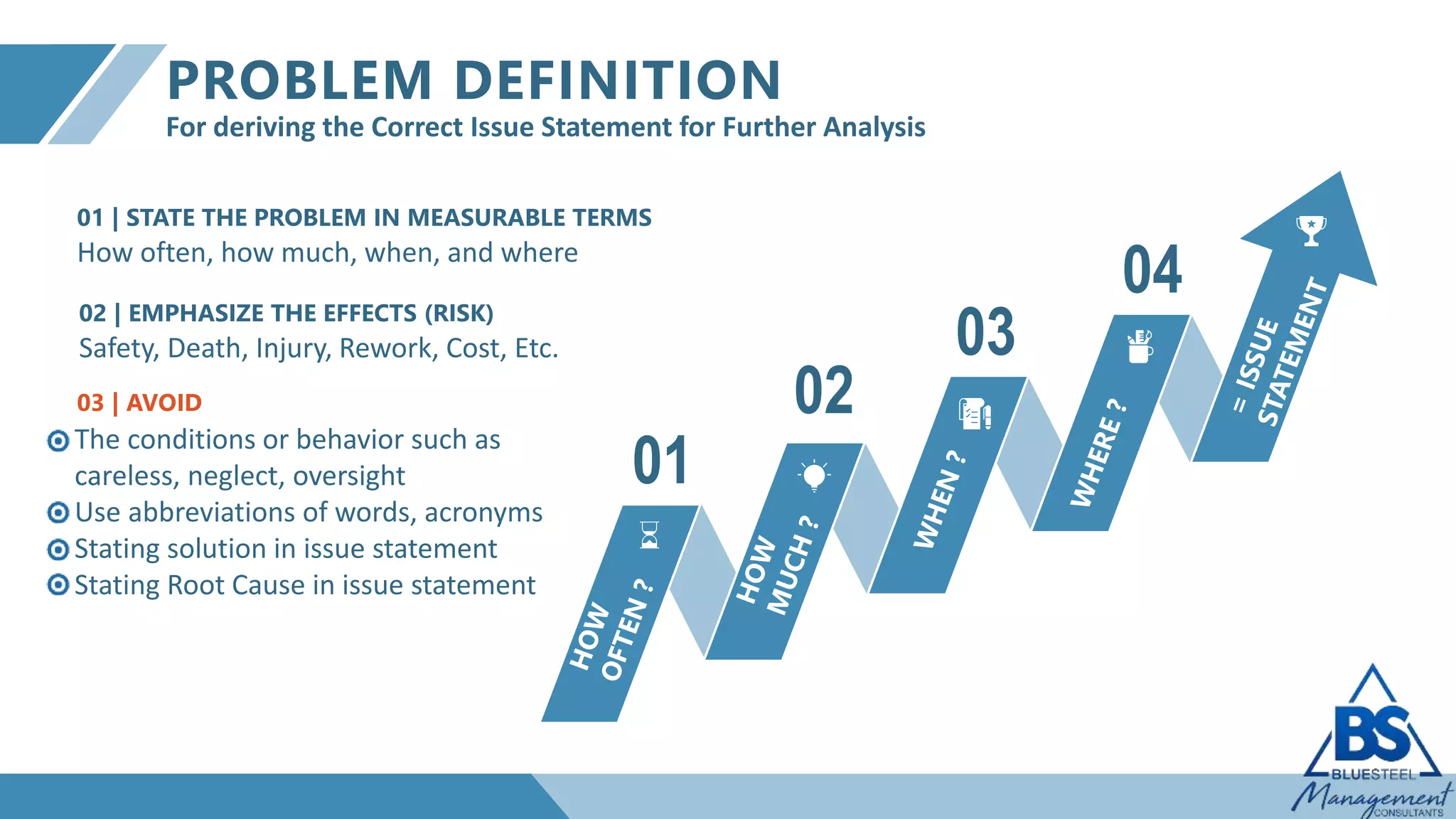

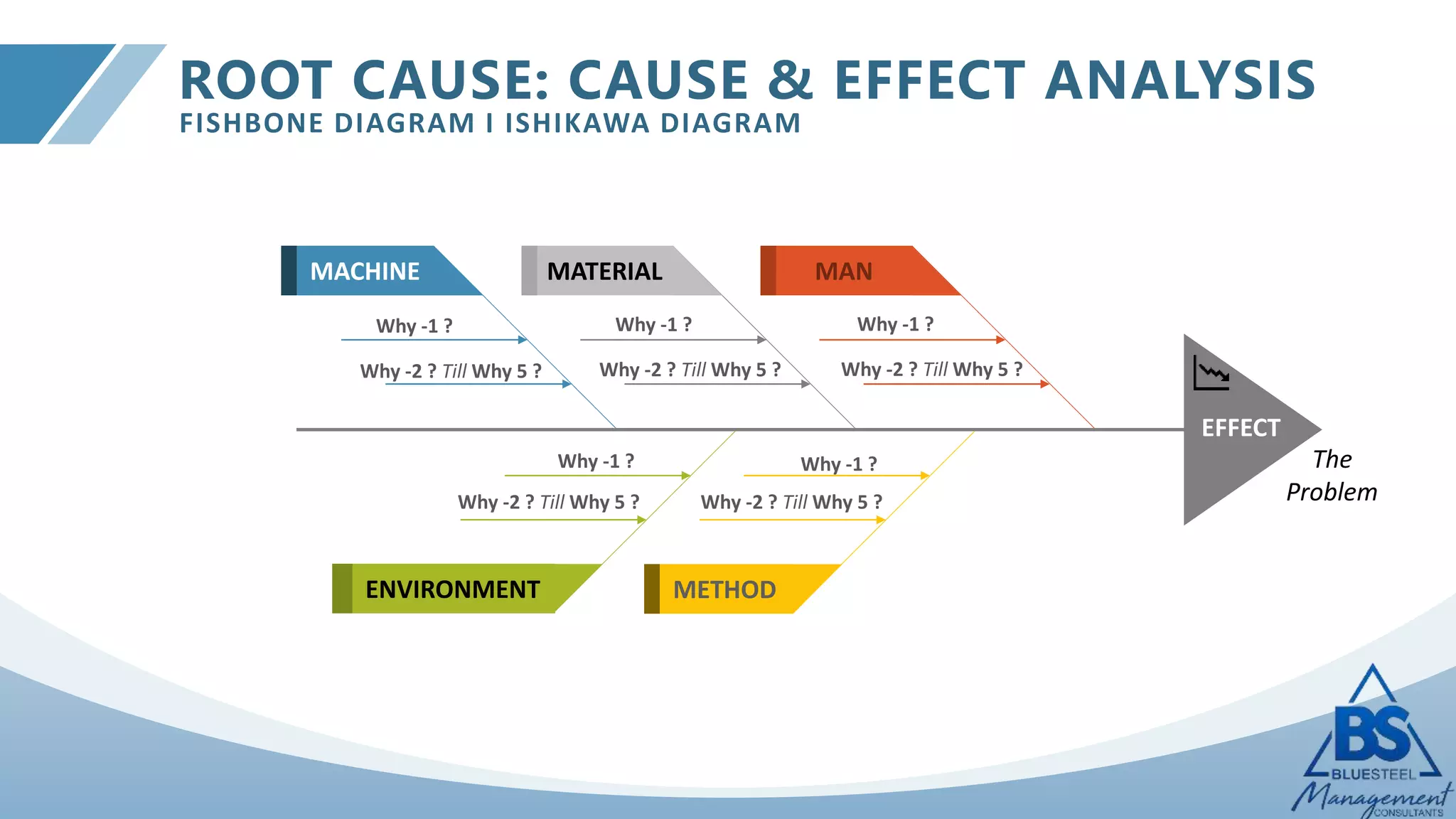

The document discusses corrective and preventive actions (CAPA) for recurring problems. It explains that CAPA is a structured process required by ISO 9001 to investigate nonconformities, determine appropriate corrections and actions, and measure effectiveness. The CAPA process involves defining the problem, investigating the root cause, developing solutions, verifying the solutions address the root cause, and checking effectiveness. Root cause analysis tools discussed include 5 whys, cause-and-effect diagrams, IS/IS NOT analysis, and the 8D (eight disciplines) approach. The document emphasizes finding facts over fault to properly solve problems.

![CAPA REQUIREMENT

The requirement for CAPA is stated in ISO 9001:2015

Clause 10.2.1 When a nonconformity occurs, including any arising from complaints, the organization shall:

a) react to the nonconformity and, as applicable: [Correction]

b) take action to control and correct it;

c) deal with the consequences; [NC can be anything deviating from the standard requirements]

d) evaluate the need for action to eliminate the cause(s) of the nonconformity, in order that it does not recur

[Corrective Action] or occur [Preventive Action] elsewhere, by:

e) reviewing and analyzing the nonconformity; [Description of NC]

f) determining the causes of the nonconformity; [RCA of NC]

g) determining if similar non conformities exist, or could potentially occur; [Platforms at Risk]

h) implement any action needed; [Correction]

i) review the effectiveness of any corrective action taken; [Effectiveness Measure]

j) update risks and opportunities determined during planning, if necessary; [Update Risk Documented Information]

k) Make changes to the quality management system, if necessary. [Update Changes in the Documented Information]

l) Corrective actions shall be appropriate to the effects of the nonconformities encountered. [Effectiveness Measure]

Clause 10.2.2 The organization shall retain documented information as evidence of:

a) the nature of the nonconformities and any subsequent actions taken;

b) the results of any corrective action.](https://image.slidesharecdn.com/correctivepreventiveactionppt-bsmc-191031143727/75/Corrective-Preventive-Action-3-2048.jpg)

![CAPA INSIGHT

Corrective & Preventive Actions [a.k.a CAPA] is a structured, formalized way to

investigate Non-Conformities and determine appropriate Corrections, Corrective

Actions and Preventative Actions and measure their effectiveness. (With Records)

Serve as a useful tool for analyzing past events, correcting existing non

conformities and preventing future events.

Goes beyond regulatory compliance to positively impact the customers by

increasing the value of our products and services.](https://image.slidesharecdn.com/correctivepreventiveactionppt-bsmc-191031143727/75/Corrective-Preventive-Action-4-2048.jpg)

![ROOT CAUSE

Tools

• Asking Why ?

To the problem statement

for 5 times so as to derive

the Root Cause

5 WHYS

• Finding the

underlying Causes

by asking Question

such as

• WHAT – IS/NOT

• WHEN – IS/NOT

• WHERE – IS/NOT

• EXTENT – IS/NOT

IS/ IS NOT • The Eight Disciplines of

Problem Solving (8D)

1) Team Formation

2) Problem Description

3) Implementing Interim

Containment Actions

4) Defining Problem Root

Causes

5) Developing Permanent

Corrective Actions

6) Implementing Permanent

Corrective Actions

7) Preventing Reoccurrences

8) Team Recognition

8D

CAUSE & EFFECT

• Finding the underlying

Causes from the Effect

[Problem]

• MAN

• MATERIAL

• MACHINE

• METHOD

• ENVIRONMENT](https://image.slidesharecdn.com/correctivepreventiveactionppt-bsmc-191031143727/75/Corrective-Preventive-Action-10-2048.jpg)

![CORRECTION

CORRECTIVE ACTION

& PREVENTIVE ACTION

CORRECTION

Temporary action taken to eliminate a

dectcted non-conformance [Rework, Sorting,

Scrap, Repair]

E.g: Replace Part

CORRECTIVE

ACTION

CORRECTIVE ACTION

Action taken to eliminate the underlying Root

Cause of the problem in order to prevent its

RECURRENCE

E.g: By RCA Approach

PREVENTIVE ACTION

Action taken to eliminate the

underlying Root Cause of a

potential problem in order to

prevent its occurance

OCCURRENCE

E.g: By RCA Approach, Can be

horizontal deployment of

Corrective Action](https://image.slidesharecdn.com/correctivepreventiveactionppt-bsmc-191031143727/75/Corrective-Preventive-Action-21-2048.jpg)

![CORRECTIVE

& PREVENTIVE ACTION

About the Trainer

PRANEET SURTI

Management Consultant

[Lead Auditor ISO 9001:2015, B.E Mechanical Engineering]

BLUE STEEL MANAGEMENT CONSULTANTS

Cell : +918347008127; +91 8109773774

Email: praneetsurti20@gmail.com

LinkedIn: http://in.linkedin.com/in/praneetsurti

Diversified Consulting Solutions, Unvarying Sustainable Quality

"In times like these it is good to remember that

there have always been times like these."

— Paul Harvey](https://image.slidesharecdn.com/correctivepreventiveactionppt-bsmc-191031143727/75/Corrective-Preventive-Action-30-2048.jpg)