1) The document provides definitions and explanations of terms related to Quality Control Circles (QCC) such as quality, problem, kaizen, PDCA cycle, and standardization.

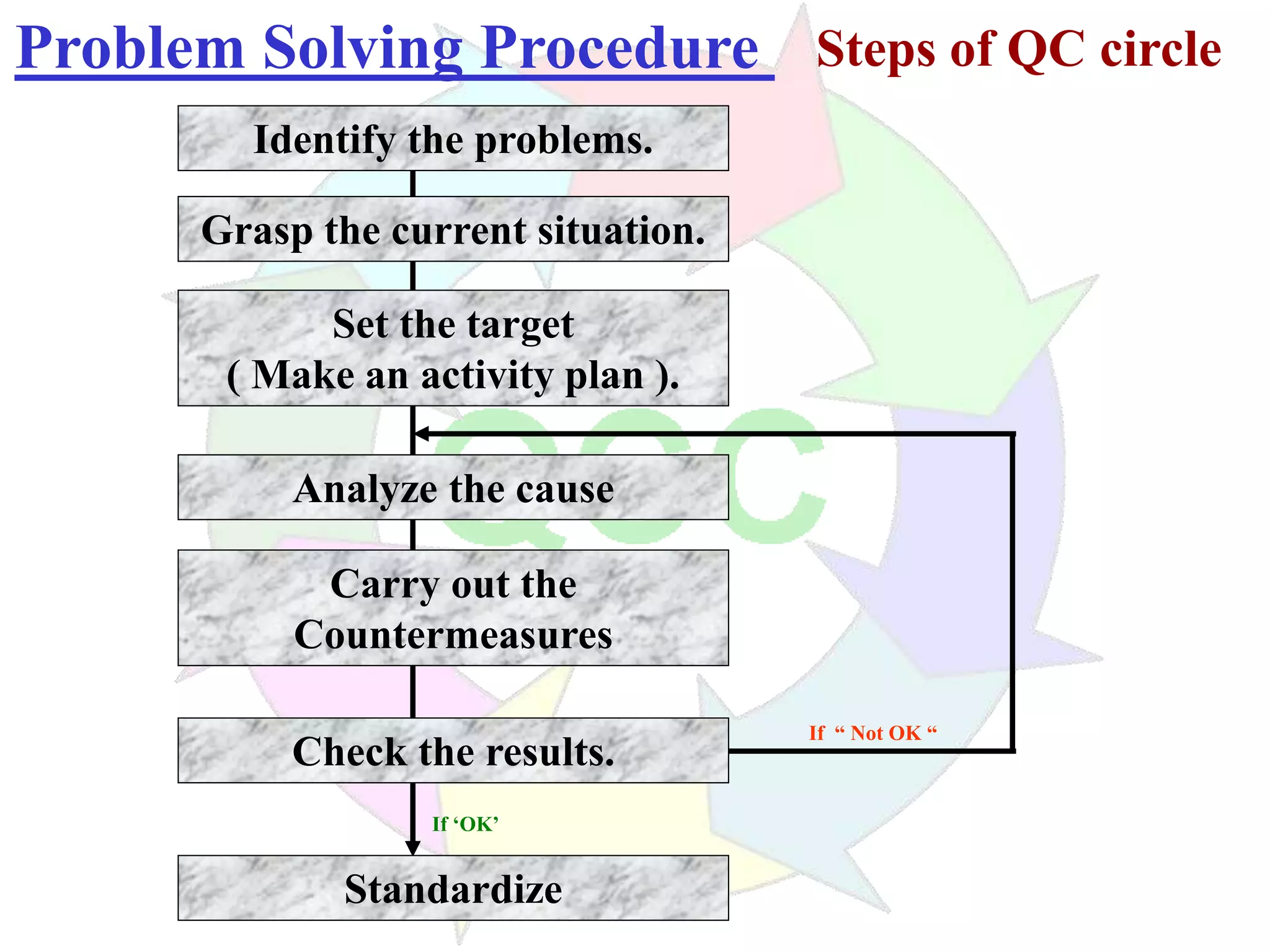

2) It describes the 3 basic principles of QCC as rotating the PDCA cycle, judging and acting based on facts and data, and performing standardization.

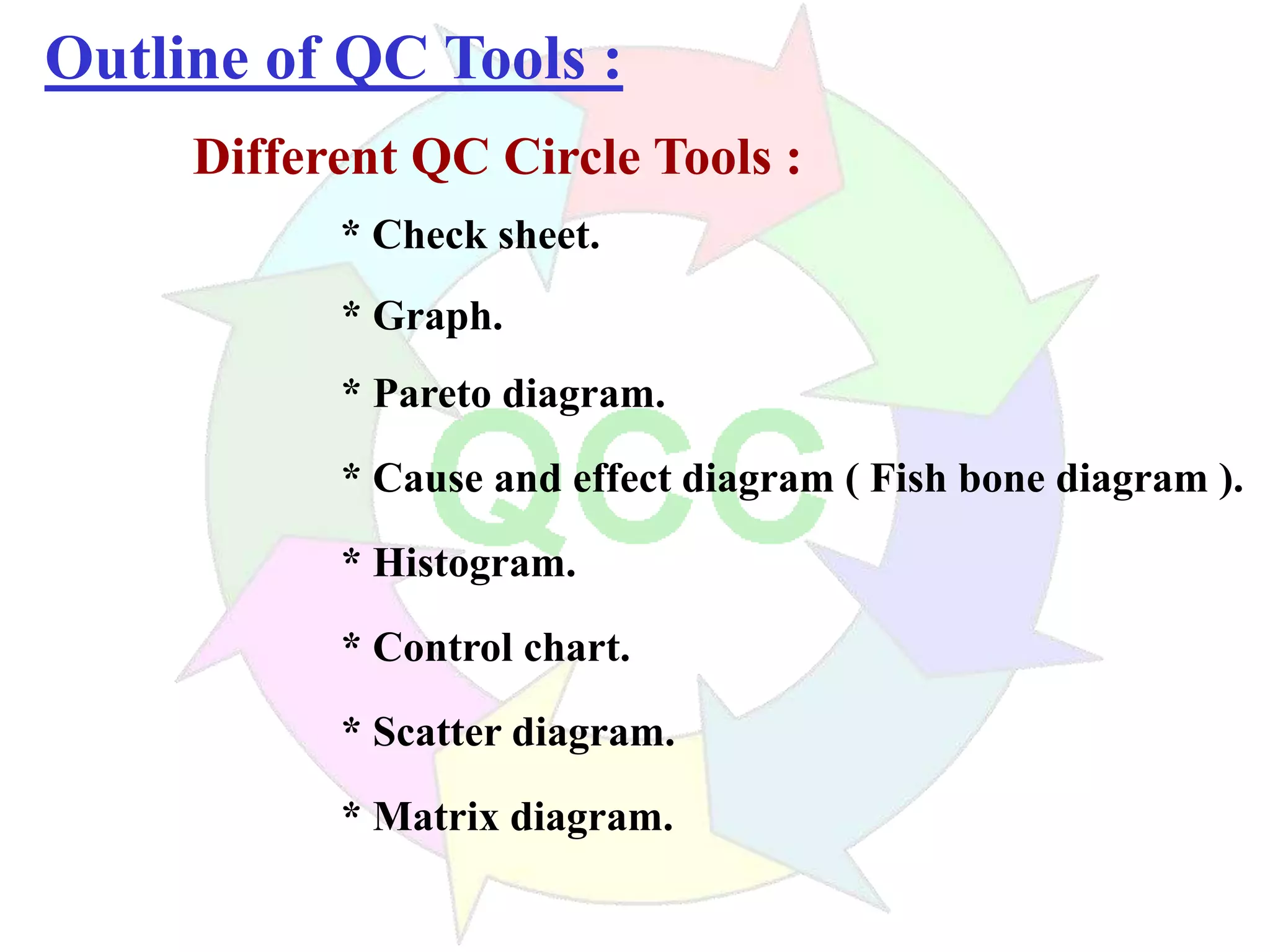

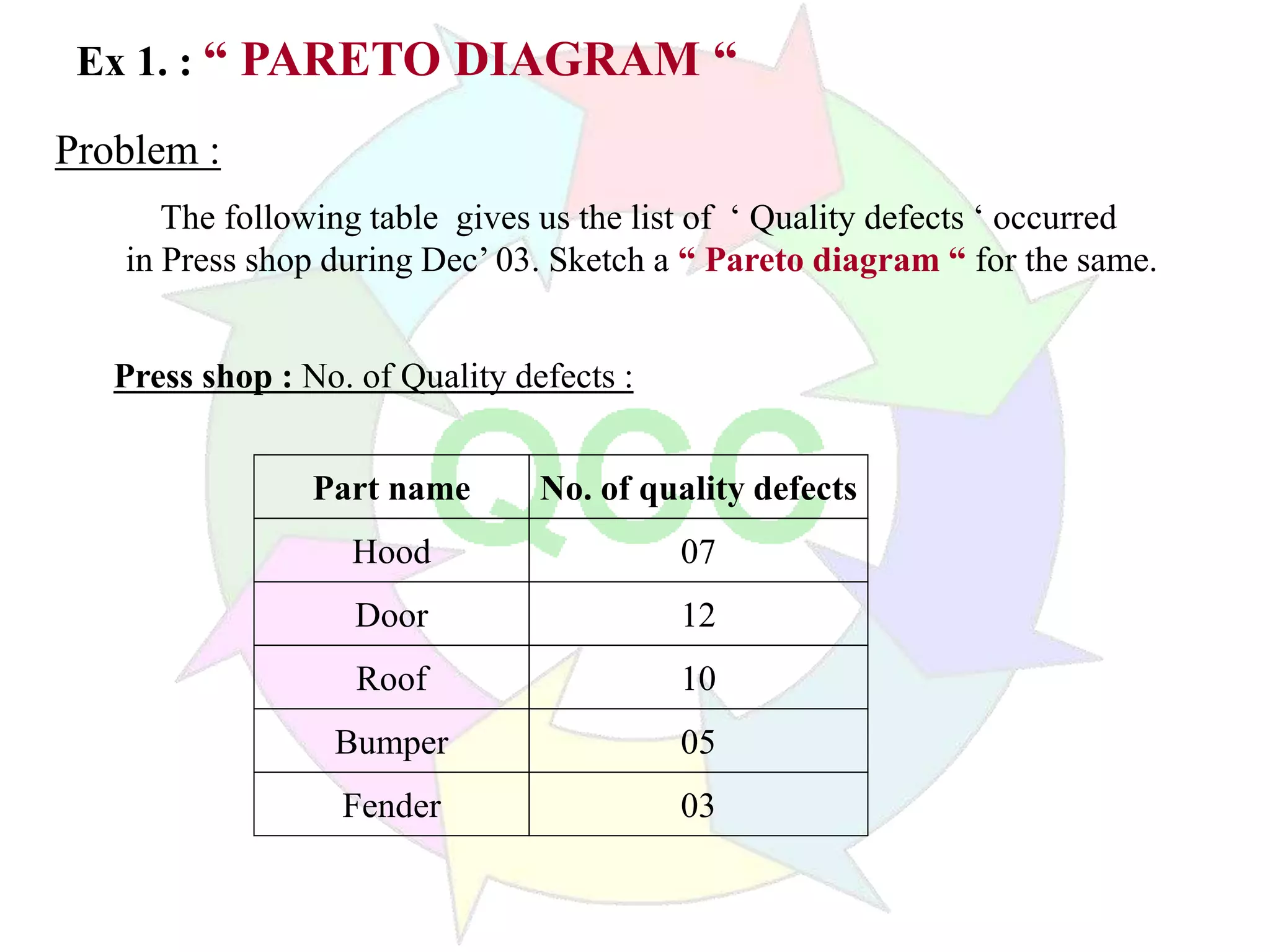

3) Examples of two quality tools, Pareto diagram and cause-and-effect diagram, are shown to illustrate problems in a press shop and causes of dents on a rear door panel.