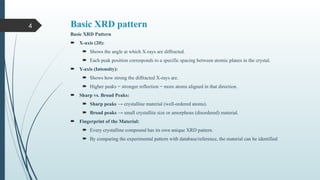

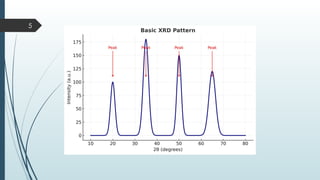

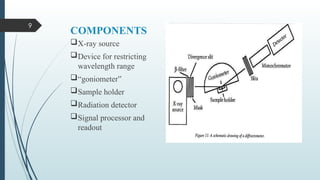

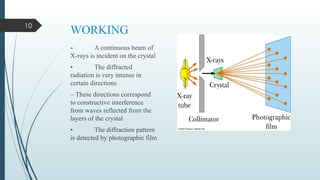

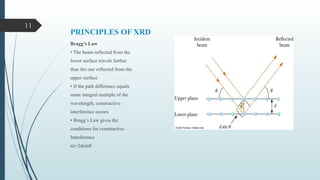

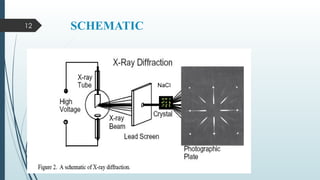

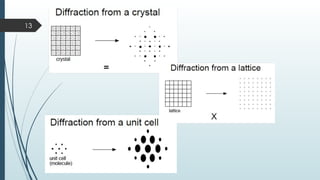

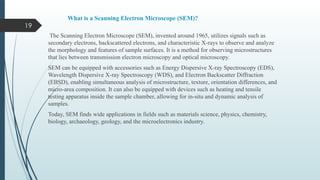

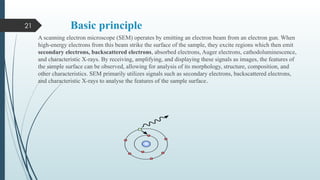

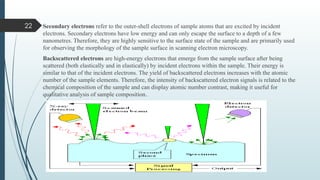

XRD and SEM are the most important techniques in chemistry specially inorganic chemistry. These analysis are used for the surface phenomena of a crystalline solid. XRD explain Thier crystallinity while SEM tells us about Thier surface properties like surface area and particle size.