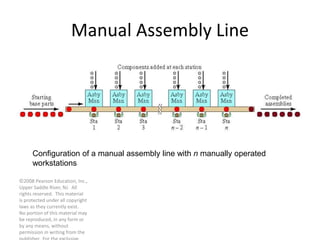

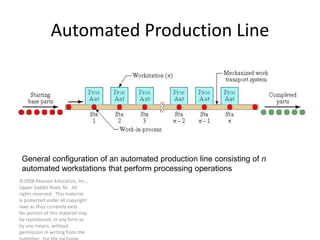

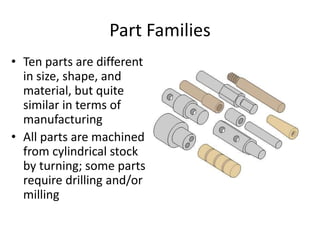

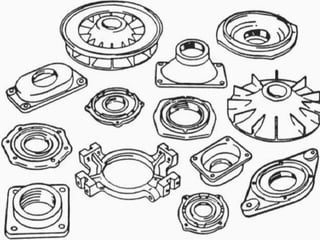

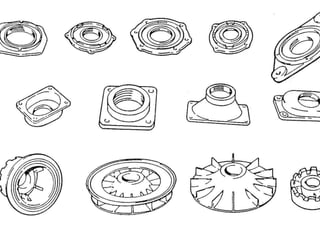

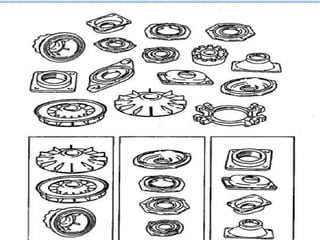

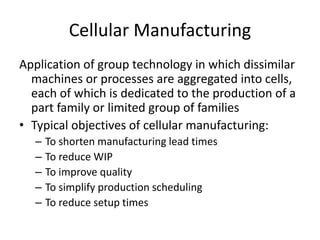

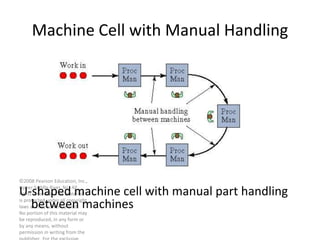

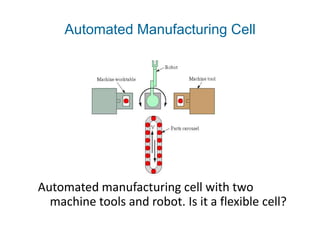

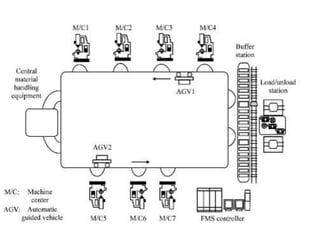

This document provides an overview of manufacturing systems, including integrated equipment and human resources that perform processing and assembly operations. It details various types of manufacturing systems, their components, classifications based on operations, workstation numbers, automation levels, and product variety. Additionally, it discusses single-station manufacturing cells, manual assembly lines, automated production lines, and the concept of group technology in cellular manufacturing.