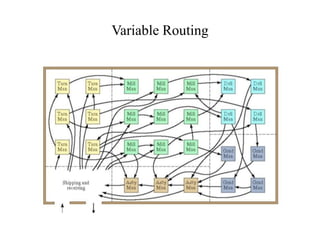

This document discusses different types of manufacturing systems. It describes manufacturing systems as consisting of production machines, material handling systems, computer control systems, and human resources. The document outlines different types of production machines based on level of automation, from manually operated to fully automated machines. It also discusses different types of manufacturing system layouts including single station cells, multi-station systems with fixed routing along an assembly line, and multi-station systems with variable routing to different workstations. The document provides examples and advantages of different manufacturing system configurations.