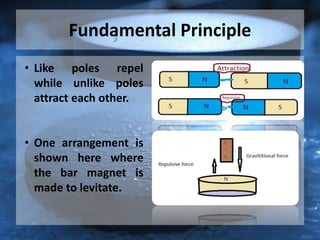

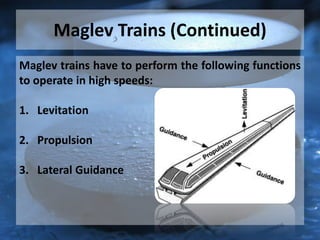

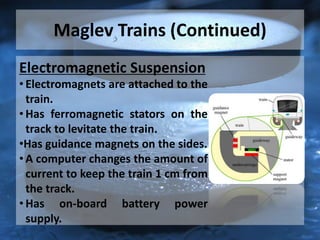

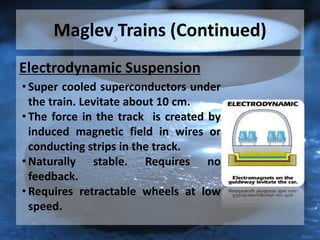

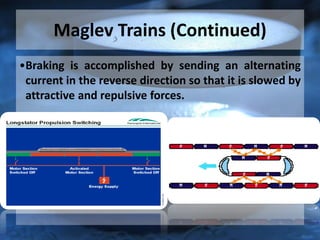

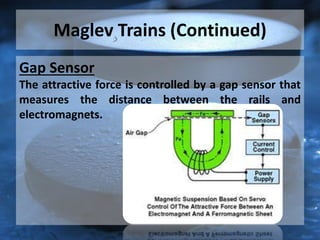

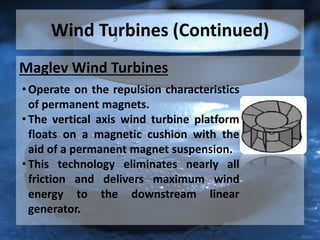

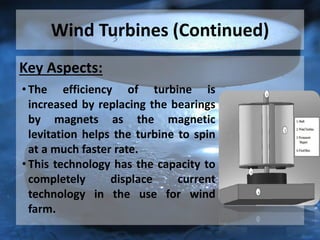

The document discusses magnetic levitation (maglev), a technology that suspends objects using magnetic fields, with applications including maglev trains, wind turbines, and space propulsion. Key features of maglev trains include levitation, propulsion, and lateral guidance, utilizing either electromagnetic or electrodynamic suspension systems. The potential advantages of maglev technology include energy efficiency, reduced pollution, and safety improvements, although high initial costs and incompatibility with existing rail lines are noted challenges.