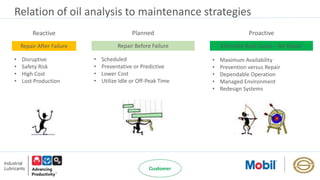

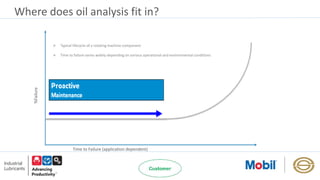

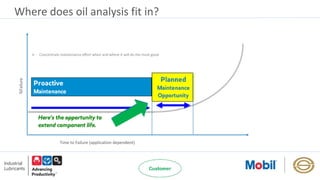

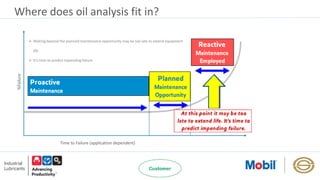

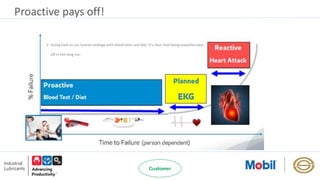

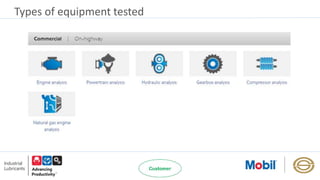

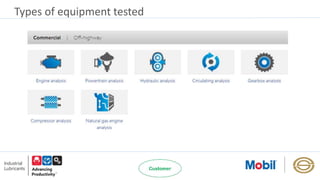

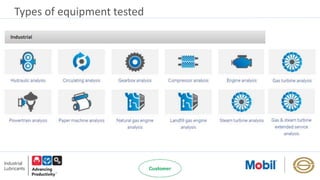

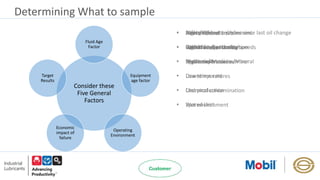

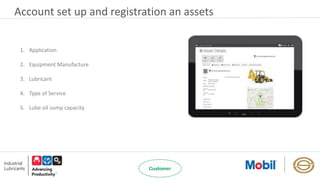

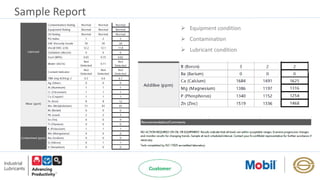

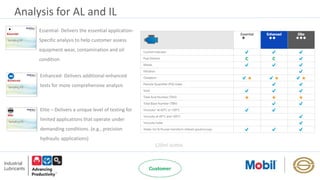

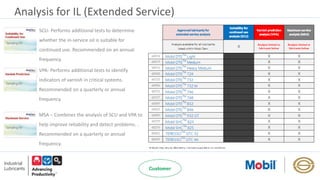

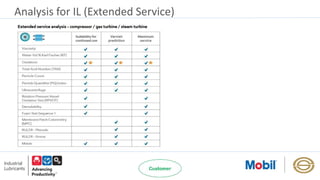

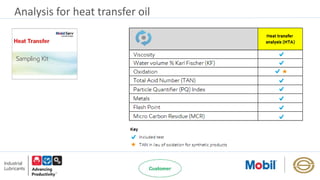

The document outlines ExxonMobil's Mobil ServSM services aimed at enhancing equipment performance through expert lubrication engineering and analysis. Key offerings include plant studies, lubricant recommendations, training, and advanced oil analysis to monitor and improve lubricants' effectiveness and equipment reliability. By implementing proactive maintenance strategies, customers can reduce downtime and extend equipment and lubricant life.