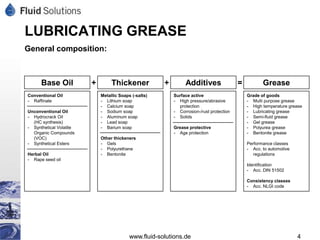

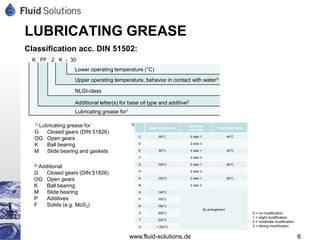

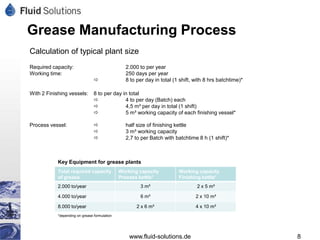

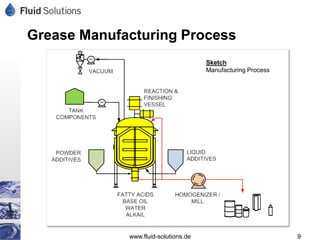

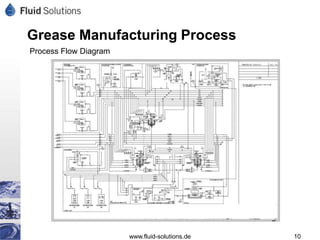

This document discusses lubricating grease, including its definition, composition, classifications, applications, and the grease manufacturing process. It defines grease as a solid or semi-fluid product made by dispersing a thickening agent in a liquid lubricant. The document outlines the key components of grease, classifications according to consistency and applications, and provides an overview of the grease production process including typical plant sizing and key equipment.