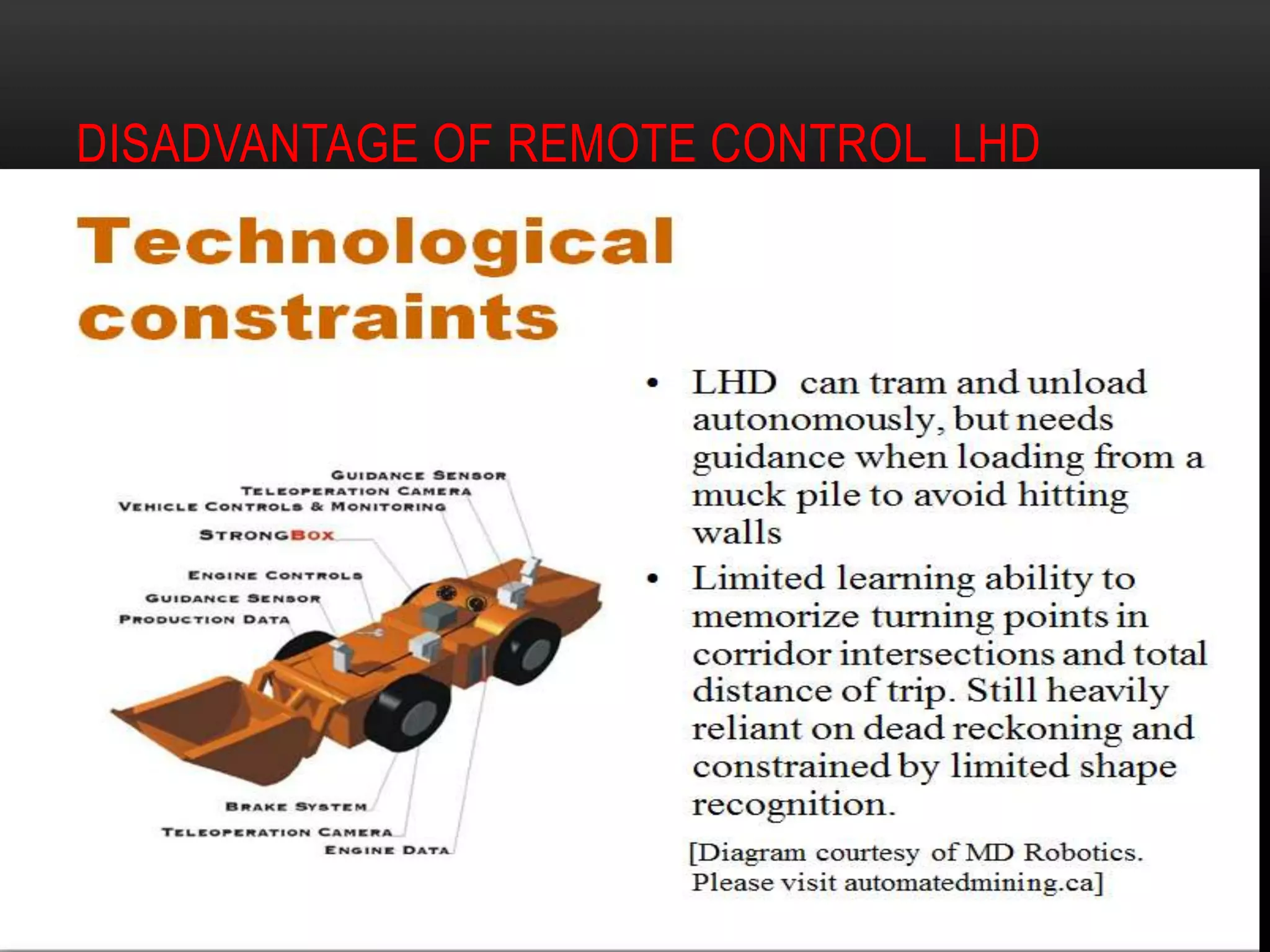

The document discusses load haul dump (LHD) trucks, which are specialized machines used in underground mining to scoop extracted ore, load it into carts, and dump it for crushing. It describes the internal components of LHD trucks and how they are designed to fit in restricted mine spaces. The document notes that LHD trucks play an important role in underground haulage and that technology is advancing, including the development of remote-controlled and more powerful and efficient narrow-vein LHD trucks. However, it also states that remotely controlling LHD trucks can make maneuvering more awkward due to their size.