The document discusses different methods for mucking and loading ore in underground mines, including:

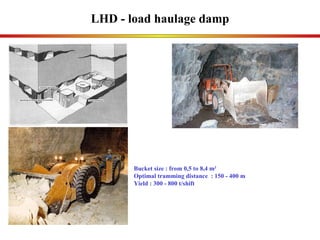

- LHD (load haulage damp) buckets that range from 0.5 to 8.4 m3 and can yield 300-800 tonnes per shift over 150-400 m tramming distances.

- Slushers with 0.22 to 0.8 m3 buckets that can yield 30-100 tonnes per shift over 20-50 m distances.

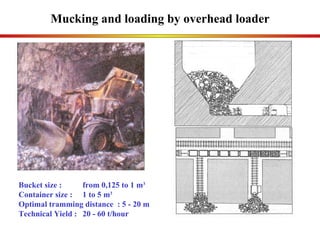

- Overhead loaders with 0.125 to 1 m3 buckets and 1 to 5 m3 containers that can yield a technical rate of 20-60 tonnes per hour over 5-20 m distances.

- Factors that influence production