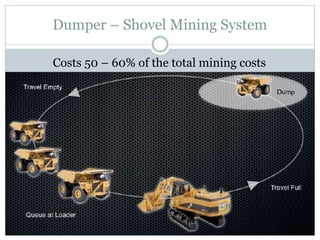

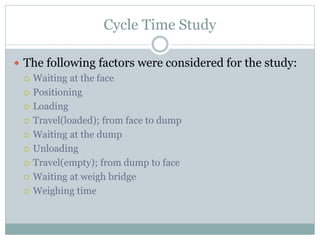

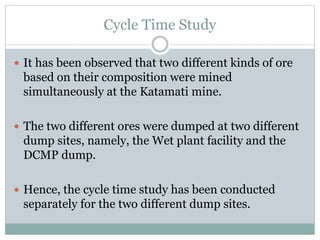

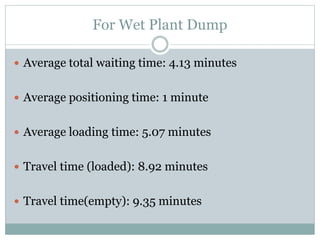

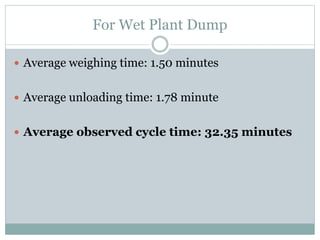

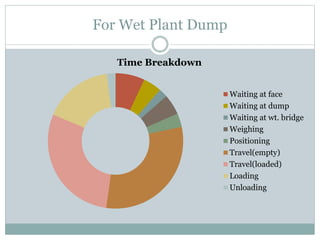

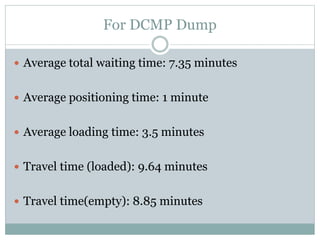

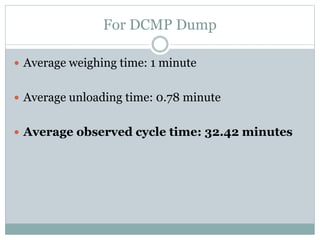

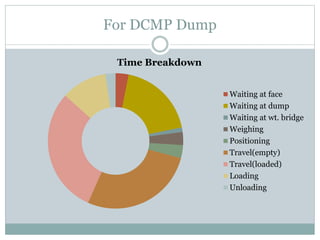

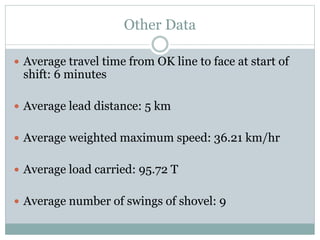

The document details a study on optimizing dumper cycle time at the Katamati iron ore mine, focusing on factors affecting efficiency, current performance metrics, and the need for improvement. It presents data on average cycle times for two dump sites, highlighting issues such as long waiting times, operator absence, and safety concerns. Recommendations include increasing operator numbers, staggering shifts to reduce idle time, implementing advanced fleet management systems, and ensuring safety compliance with speed regulations.