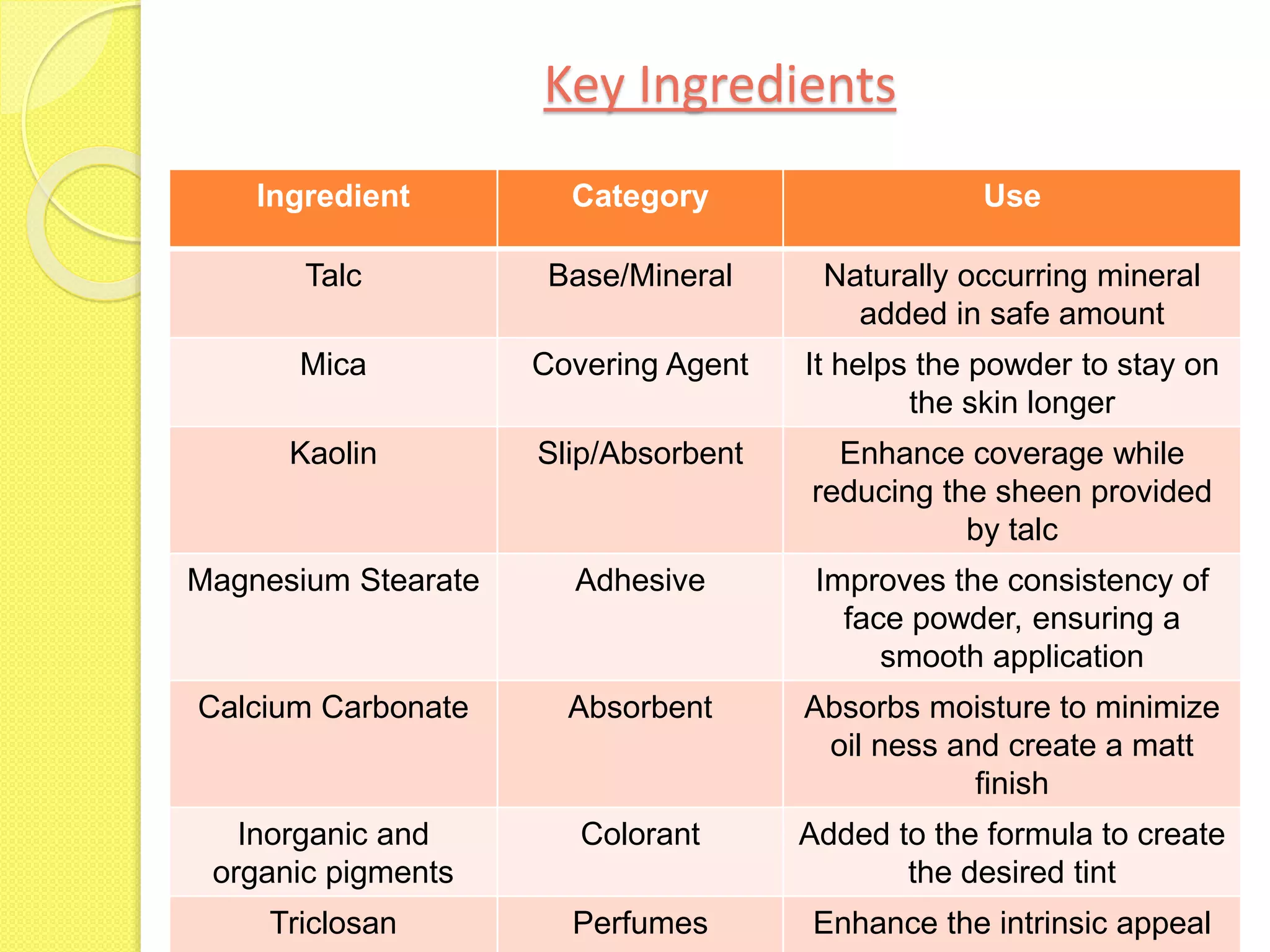

This document summarizes a seminar presentation on quality control checking for face powder. It defines face powder as a cosmetic product used to complement skin color and provide a smooth finish. The ideal properties and characteristics of face powders are discussed. Different types of face powders are described based on skin type, texture, and pigmentation. Methods for preparing face powders including wet, dry, and damp methods are outlined. Key quality control tests for face powders including shade, color dispersion, pay-off, pressure, breakage, flow, particle size, abrasiveness, and moisture content are summarized.