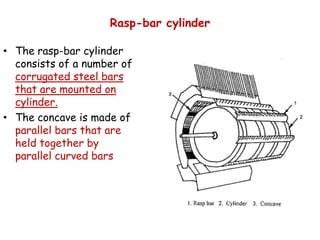

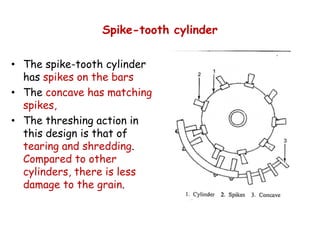

The document discusses the process and methods of threshing, particularly in Ethiopia, emphasizing traditional techniques and associated challenges such as high postharvest losses. It details the components of mechanical threshers, their operational principles, factors affecting efficiency, and comparisons between various types of threshing cylinders. Additionally, the document highlights advancements in technology, notably the use of combine harvesters that streamline harvesting and threshing operations into a single process.