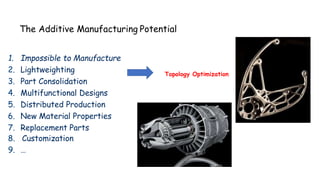

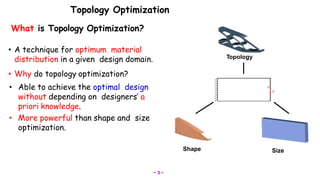

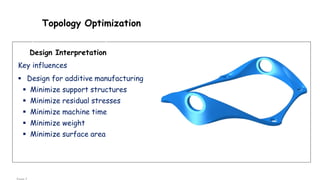

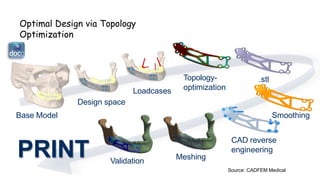

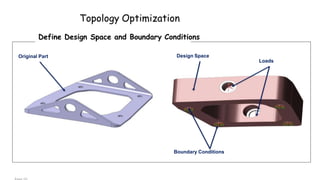

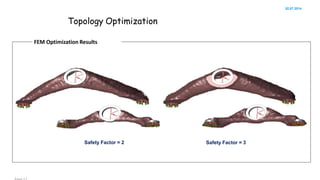

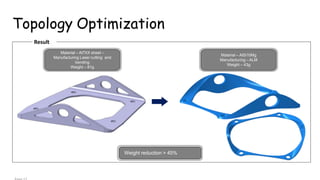

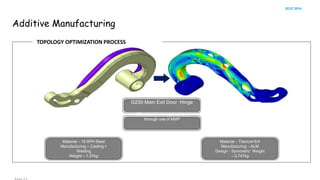

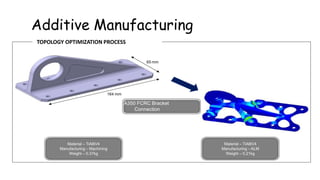

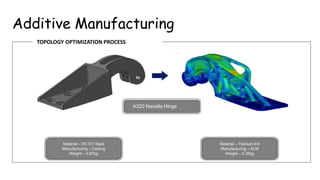

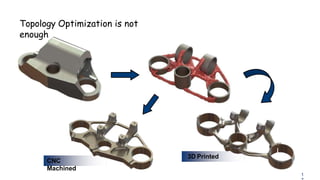

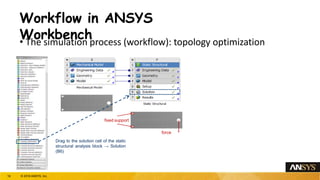

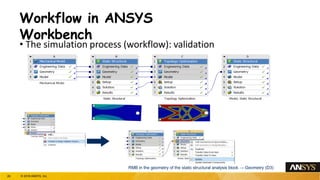

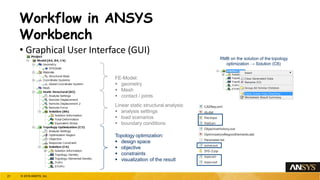

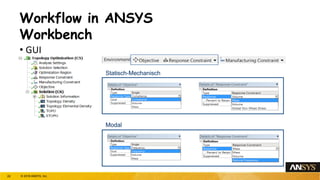

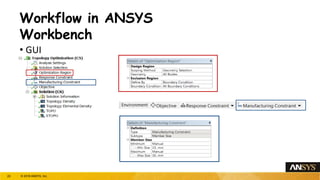

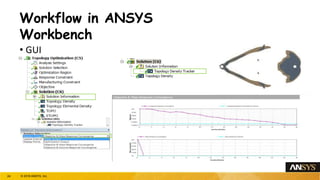

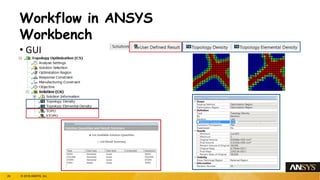

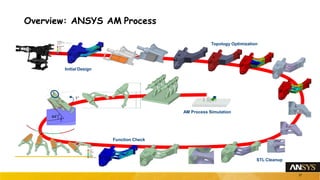

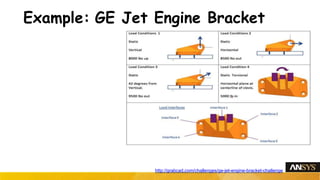

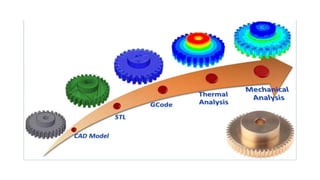

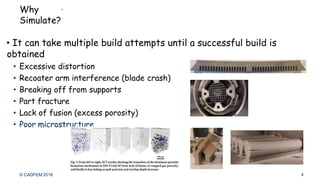

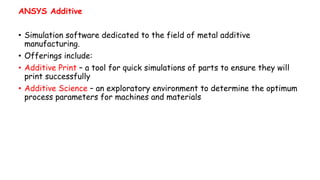

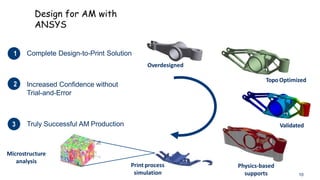

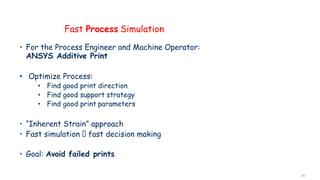

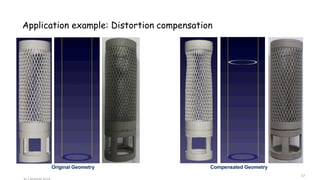

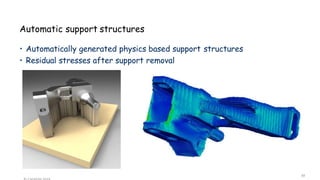

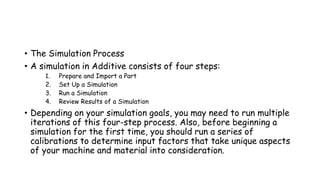

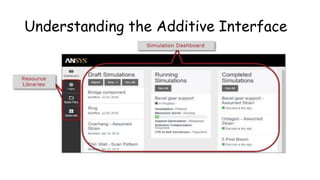

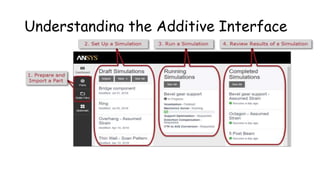

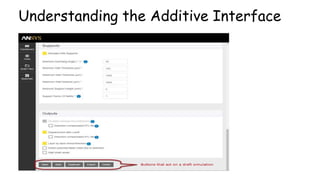

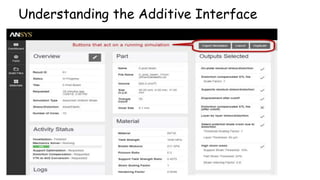

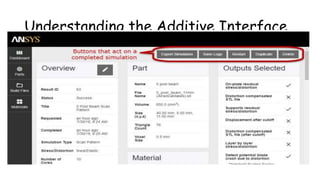

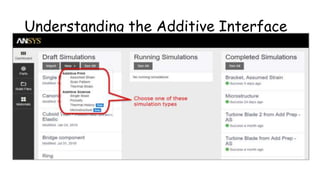

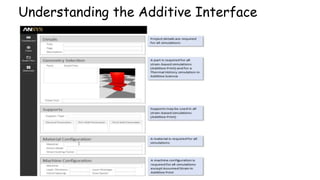

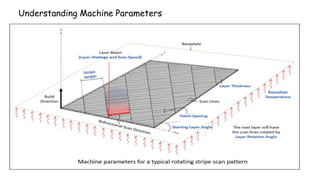

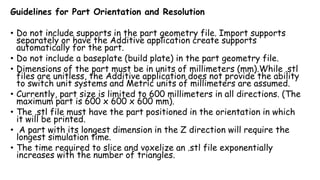

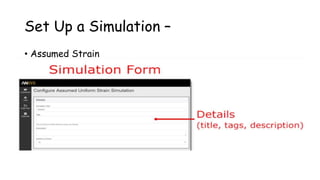

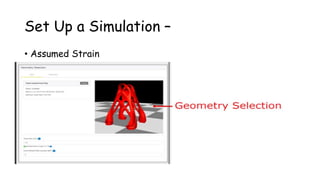

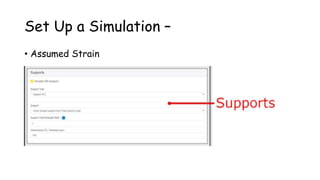

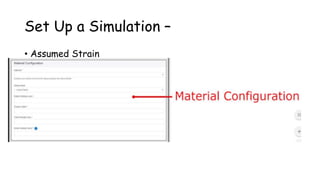

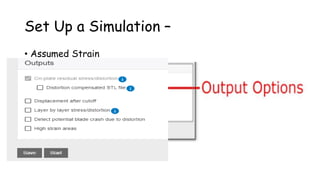

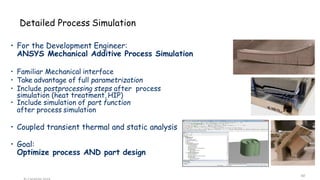

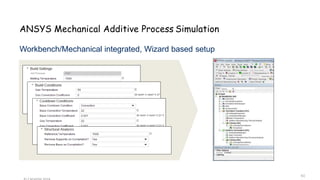

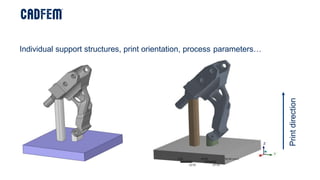

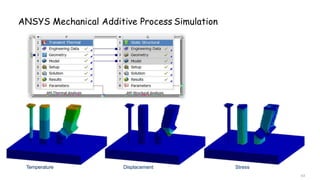

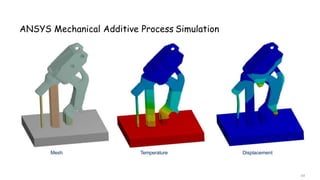

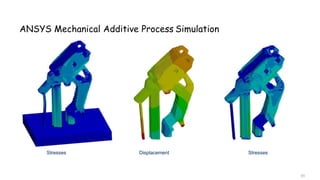

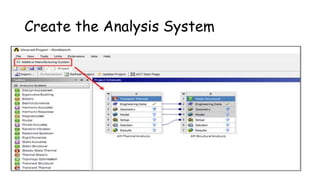

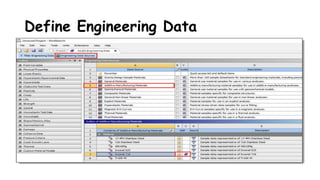

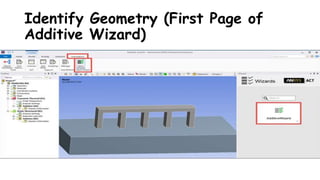

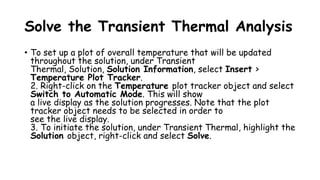

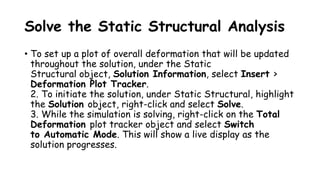

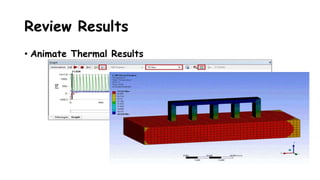

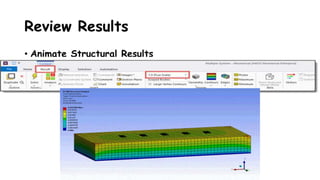

The document discusses advanced techniques in additive manufacturing, particularly focusing on topology optimization using ANSYS software. It highlights the benefits of topology optimization such as material efficiency, lightweight designs, and improving part performance while reducing costs. The workflow involves several simulation steps to ensure successful manufacturing processes and addresses challenges like distortion and support structures in 3D printing.

![BAHIR DAR UNIVERSITY

BAHIR DAR INSTITUTE OF TECHNOLOGY (BiT)

FACULTY OF MECHANICAL AND INDUSTRIAL

ENGINEERING

Rapid Prototyping & Reverse Engineering

[MEng6123]

Tools for Additive Manufacturing

ANSYS](https://image.slidesharecdn.com/lecture06-201226210034/85/Lecture-06-Tools-for-Additive-Manufacturing-ANSYS-1-320.jpg)