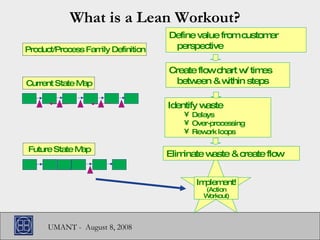

This document provides an overview of applying Lean principles to local government services. It discusses what Lean is, how Southlake, Texas has implemented Lean processes to reduce development approval times by over 300% and budget development times by 33%. It encourages focusing on eliminating waste from processes by establishing flow, implementing pull systems, and continuously improving to provide the best value and service to customers. Local governments are encouraged to apply Lean thinking to any processes where time or customer satisfaction is important.

![How can I learn more about Lean? ICMA Public Management article; September 2006 Workshop: “Lean Thinking and Government: An Oxymoron?” ICMA consulting services – Craig Rapp www.icmaleanthinking.blogspot.com TechSolve – David Krings (past ICMA president) www.techsolve.org Lean Enterprise Institute www.lean.org Celerity Consulting – David Baird [email_address]](https://image.slidesharecdn.com/umantleanpitch08-05-08-100420140415-phpapp01/85/Lean-Thinking-in-Government-Services-21-320.jpg)

![Questions? Ben Thatcher [email_address] 817/748-8005](https://image.slidesharecdn.com/umantleanpitch08-05-08-100420140415-phpapp01/85/Lean-Thinking-in-Government-Services-22-320.jpg)