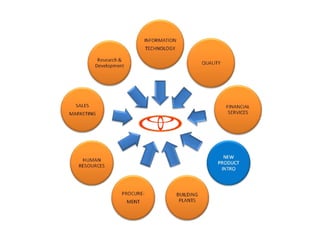

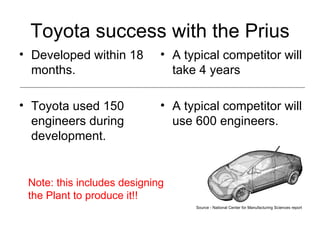

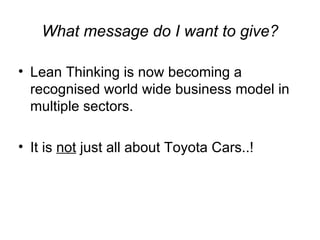

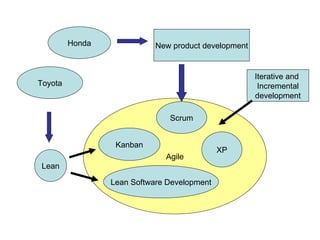

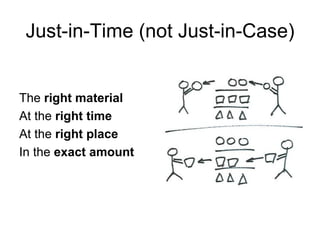

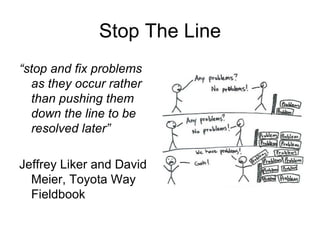

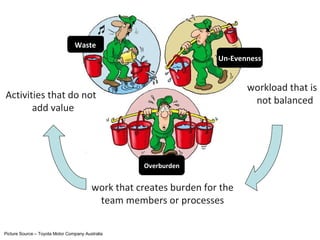

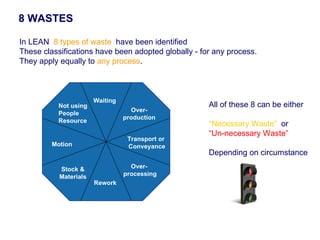

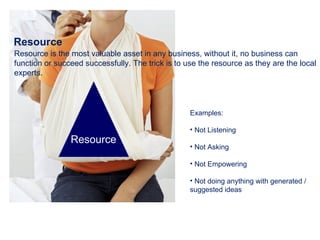

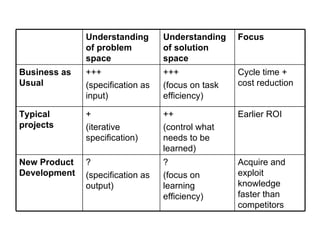

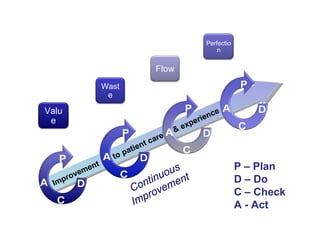

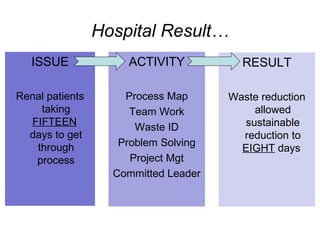

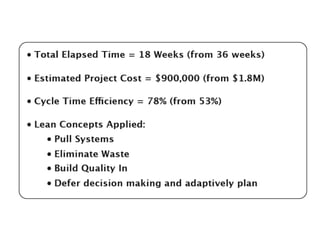

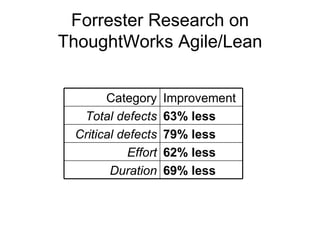

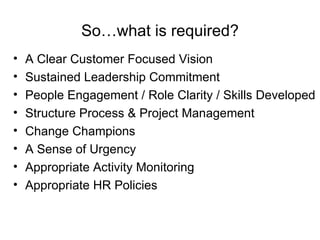

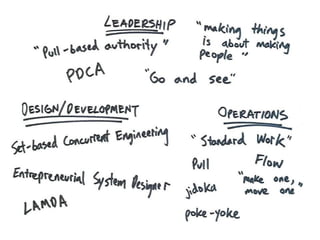

The document discusses how Toyota adopted lean principles in response to a crisis in the 1950s when it ran out of cash and fell under the control of bankers. Lean thinking was born out of Toyota's need to free up scarce cash, reduce costs, and enhance quality with little time. The document then discusses how lean principles have been applied successfully in other industries like software development to significantly reduce defects, effort, and duration of projects. It emphasizes that lean requires engaging people in problem solving and defining value from the customer's perspective to eliminate waste.

![McKinsey on Lean IT “ In our experience, applying the principles of lean manufacturing to [application development and maintenance] can increase productivity by 20 to 40 percent while improving the quality and speed of execution .” N. Kindler, V. Krishnakanthan, R. Tinaikar, “Applying lean to application development and maintenance”, McKinsey on IT, Spring 2007](https://image.slidesharecdn.com/leantimesrequireleanthinkingv7090331003458phpapp01-123976200616-phpapp01/85/Lean-times-require-lean-thinking-53-320.jpg)

![For Further Information please contact: ThoughtWorks – Jason Yip Email [email_address] Web www.thoughtworks.com.au KM&T – Paul Heaton mail [email_address] Web www.kmandt.com.au](https://image.slidesharecdn.com/leantimesrequireleanthinkingv7090331003458phpapp01-123976200616-phpapp01/85/Lean-times-require-lean-thinking-58-320.jpg)