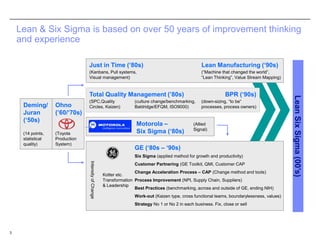

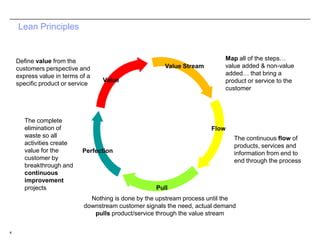

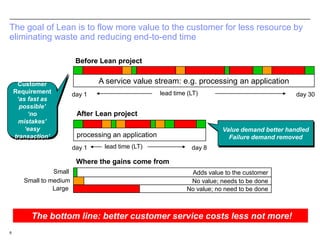

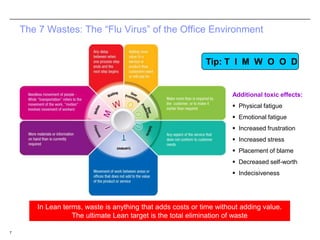

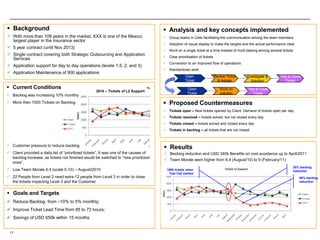

This document provides an overview of lean principles and tools. It discusses the history and evolution of lean thinking over decades, from Toyota's production system to modern lean six sigma. The core lean principles are described, including eliminating waste, respecting people, and continuously improving flow. Common lean tools and methods like value stream mapping, 5S, and A3 problem solving are also outlined. The document then presents a case study of applying lean tools to reduce the backlog of IT support tickets at a Mexican insurance company.