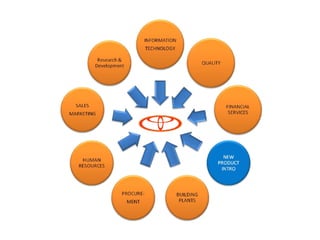

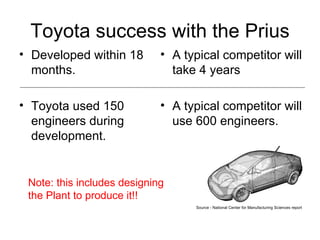

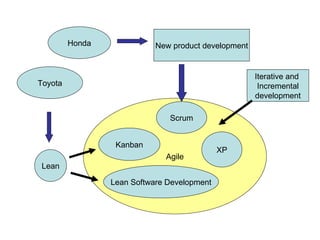

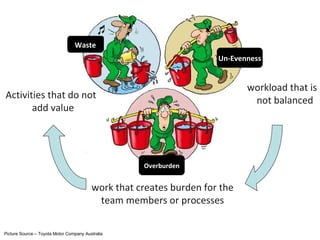

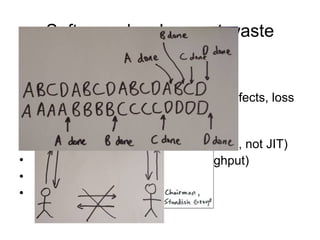

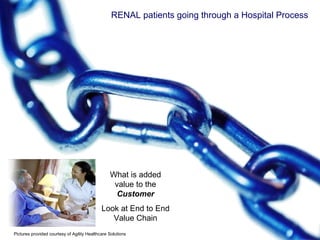

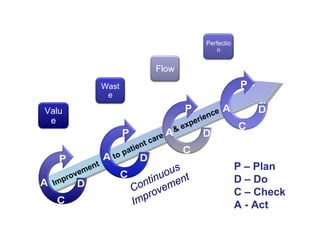

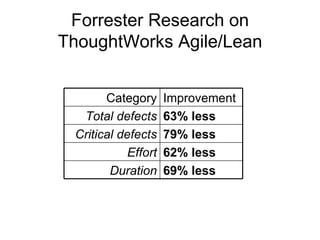

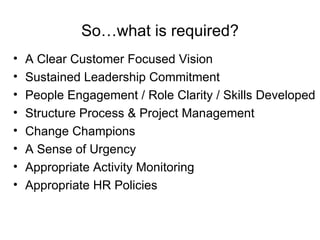

The document discusses the origins and principles of lean thinking, highlighting Toyota's response to crises and its development of the Toyota Production System. Lean methodology focuses on efficiency by eliminating waste, engaging everyone in problem-solving, and emphasizing just-in-time processes. The adoption of lean principles has shown to improve productivity and quality across various sectors, not just in automotive production.

![McKinsey on Lean IT “ In our experience, applying the principles of lean manufacturing to [application development and maintenance] can increase productivity by 20 to 40 percent while improving the quality and speed of execution .” N. Kindler, V. Krishnakanthan, R. Tinaikar, “Applying lean to application development and maintenance”, McKinsey on IT, Spring 2007](https://image.slidesharecdn.com/leantimesrequireleanthinking-v7-090331003458-phpapp01/85/Lean-Times-Require-Lean-Thinking-53-320.jpg)

![For Further Information please contact: ThoughtWorks – Jason Yip Email [email_address] Web www.thoughtworks.com.au KM&T – Paul Heaton mail [email_address] Web www.kmandt.com.au](https://image.slidesharecdn.com/leantimesrequireleanthinking-v7-090331003458-phpapp01/85/Lean-Times-Require-Lean-Thinking-58-320.jpg)