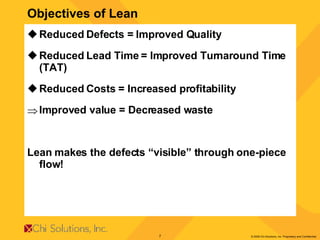

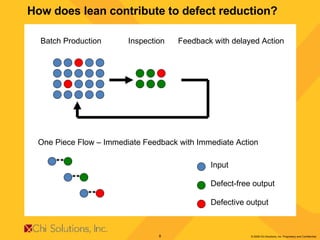

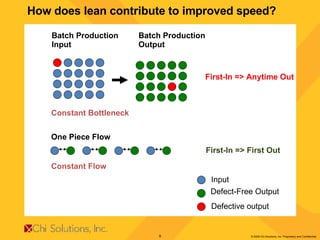

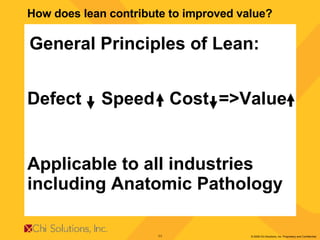

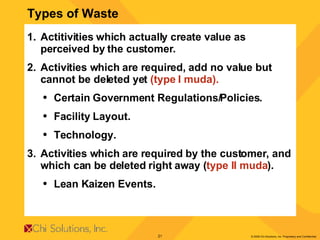

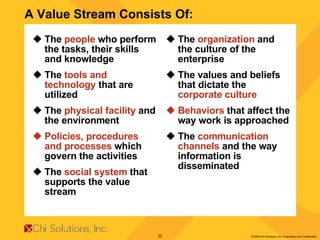

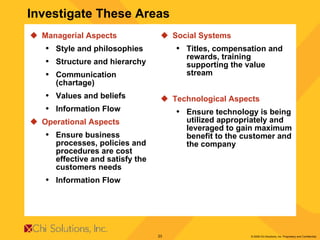

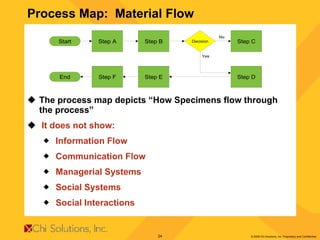

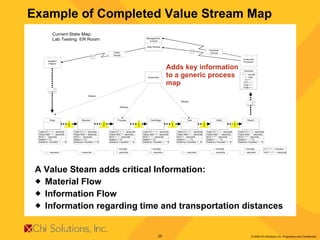

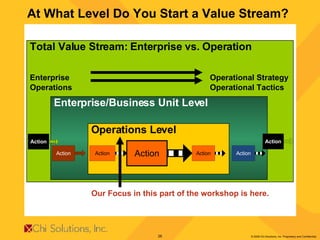

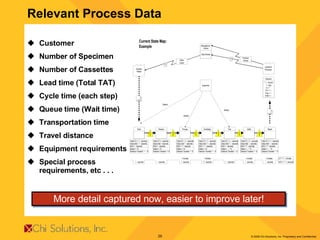

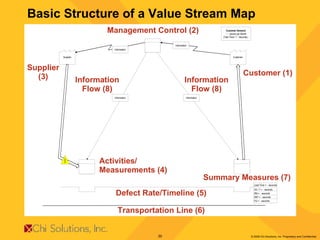

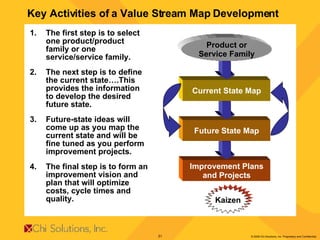

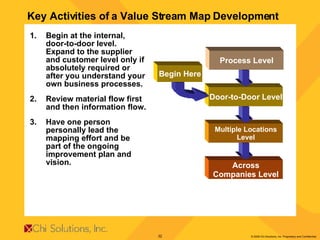

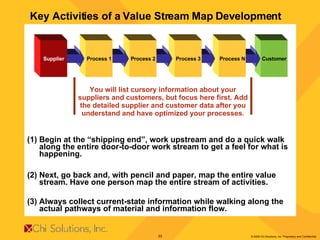

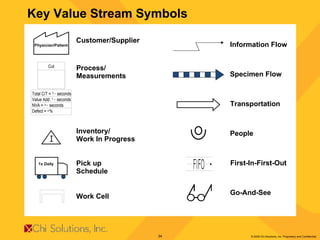

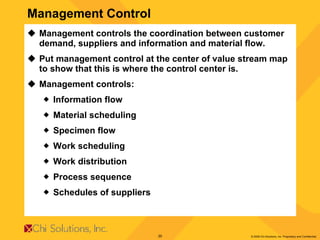

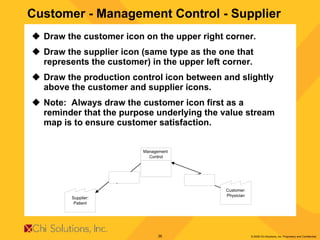

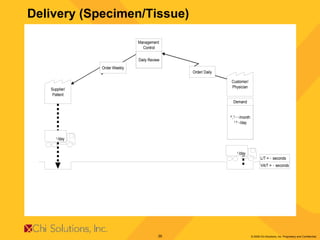

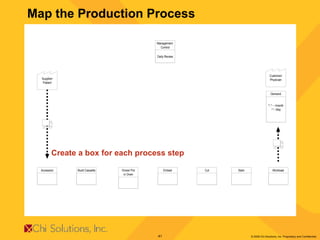

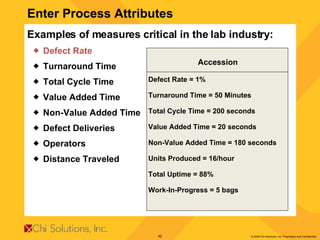

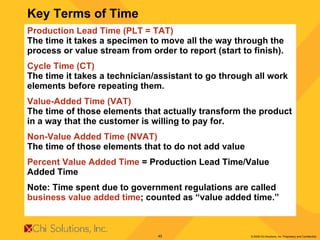

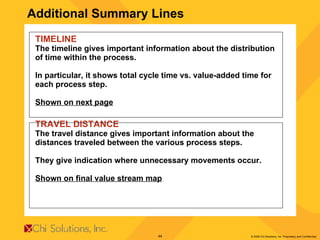

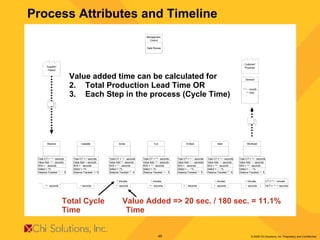

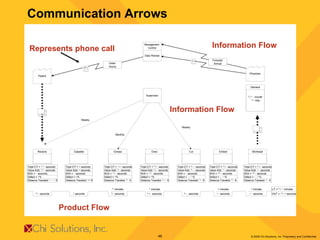

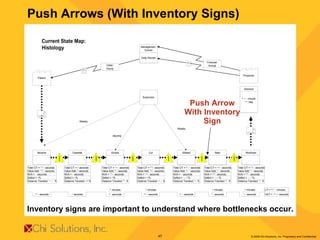

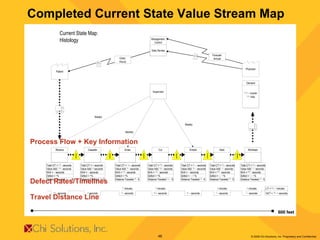

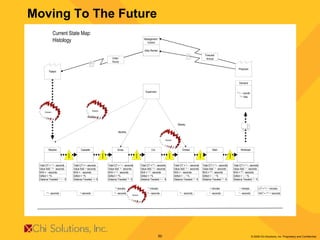

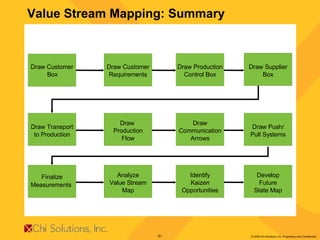

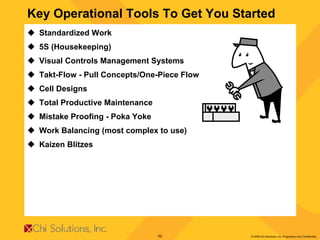

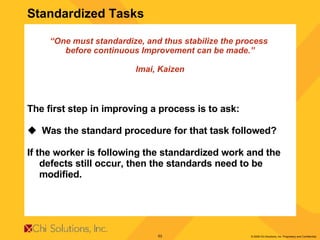

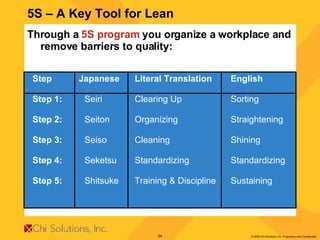

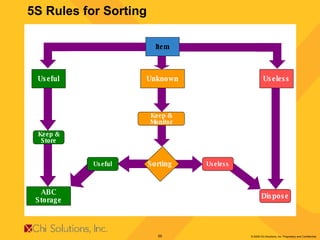

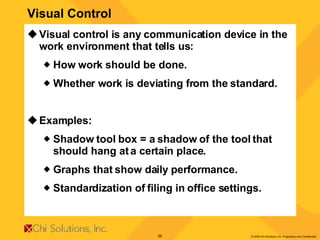

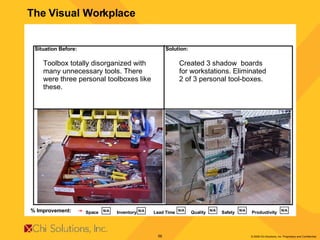

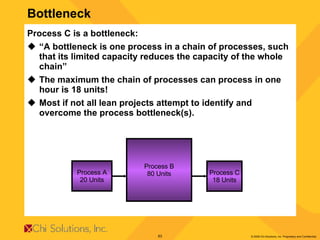

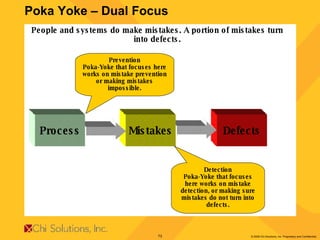

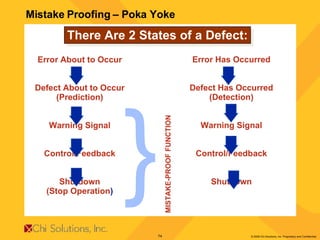

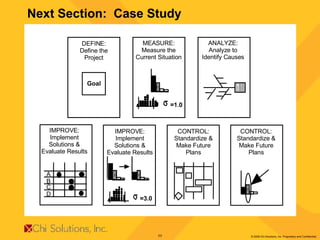

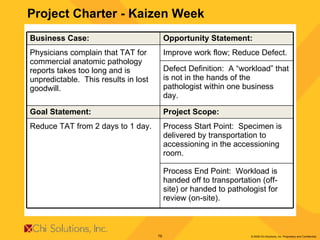

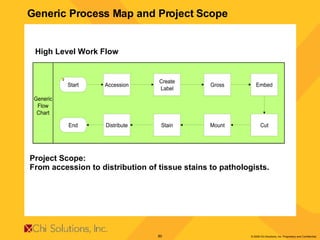

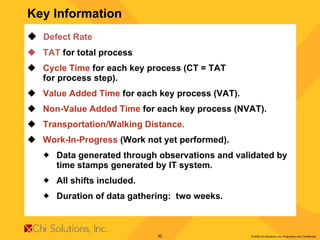

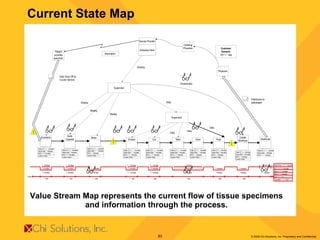

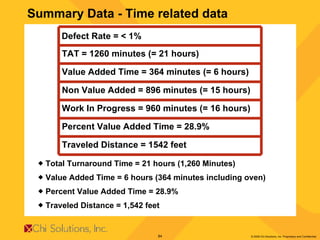

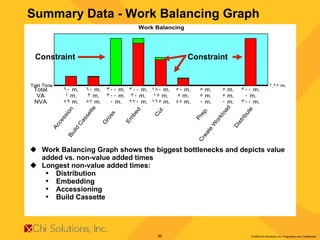

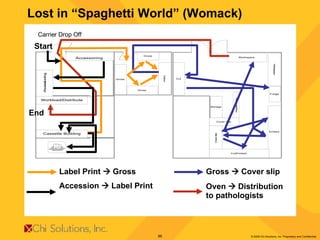

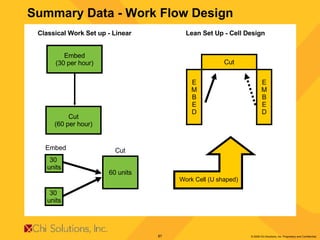

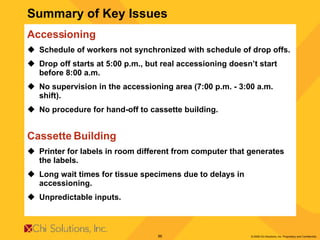

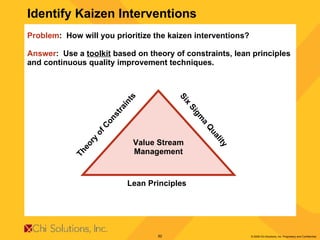

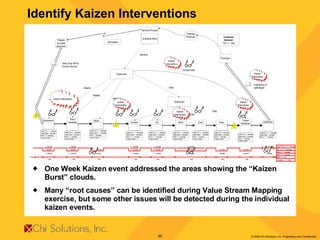

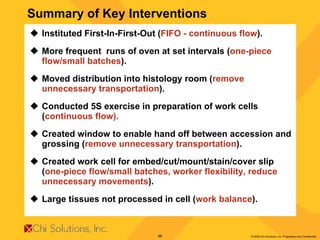

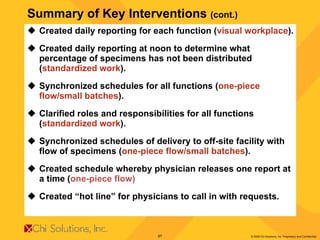

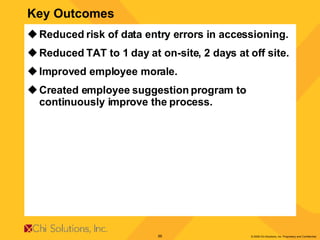

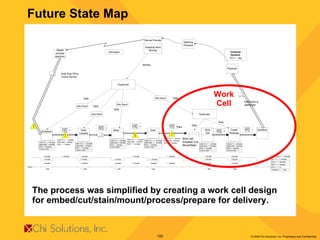

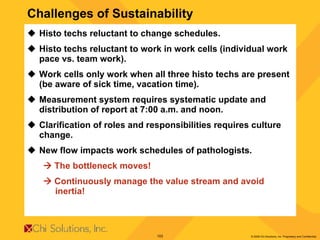

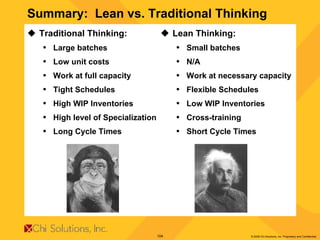

The document discusses value stream mapping as a tool for reducing defects and improving processes in anatomic pathology. It provides definitions of key lean terms like value, value stream, takt time, and describes how creating current and future state value stream maps can help identify waste and opportunities for improvement. The goals are to reduce defects, lead times and costs through techniques like one-piece flow, standard work, visual controls and 5S to ultimately improve value for customers.