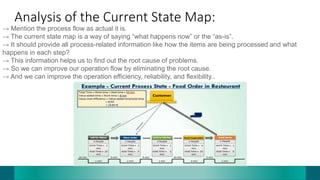

Value stream mapping (VSM) is a graphical tool used to visualize the flow of processes and information in manufacturing and other industries, aimed at eliminating waste and improving efficiency. The process involves gathering data, creating current and future state maps, and executing plans for improvement while focusing on activities that add value. Key roles in a VSM study include executive sponsors, process owners, VSM coaches, and workshop participants, all of whom collaborate to facilitate successful project outcomes.

![Team Members and Roles in VSM Study Project:

[1] Executive Sponsor:

→ Executive Sponsor is the owner of the Charter

→ He/She decide the team members for the project

→ Executive Sponsor is responsible for ensuring the member's participation.

→ Ongoing project status is presented by the Executive Sponsor.

→ He/She takes part in define the scope, start the project, Active team member of review, audit &

follow-ups committee](https://image.slidesharecdn.com/valuestreammappingvsmstudywithexample-200401195930/85/Value-stream-mapping-study-with-example-10-320.jpg)

![Team Members and Roles in VSM Study Project:

[2] Process Owner:

→ They are responsible for the whole operation flow and they lead the VSM project from beginning to

end.

→ They take ownership during the VSM event

→ All meetings, progress, and MOMs are maintained by the Process Owner.

→ Ensures action item pre-work is complete for scoping, workshop/office, and reviews

→ Conduct the review of the implementation plan at a certain interval.

→ He/She gives information to sponsor about the progress of the project.](https://image.slidesharecdn.com/valuestreammappingvsmstudywithexample-200401195930/85/Value-stream-mapping-study-with-example-11-320.jpg)

![Team Members and Roles in VSM Study Project:

[3] VSM Coach:

→ VSM coach provides coaching to Process Owner and team.

→ He/She is responsible for defining the scope of the project.

→ Gives training to the VSM team and give coaching to the team.

→ VSM Coach gives training on Lean Manufacturing to the team.

→ Provide training on lean skills to all participants.](https://image.slidesharecdn.com/valuestreammappingvsmstudywithexample-200401195930/85/Value-stream-mapping-study-with-example-12-320.jpg)

![Team Members and Roles in VSM Study Project:

[4] Workshop/office Participants:

→ Participate in the VSM project as a Subject Matter Expert (SME)

→ All Workshop/office Participants are responsible for the operation steps.

→ They support the VSM project successfully run.](https://image.slidesharecdn.com/valuestreammappingvsmstudywithexample-200401195930/85/Value-stream-mapping-study-with-example-13-320.jpg)