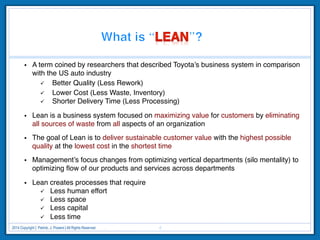

This document introduces the concept of Lean, emphasizing its principles aimed at maximizing customer value by eliminating waste. It discusses how Lean transforms organizational processes, enhances quality, reduces costs, and improves customer satisfaction. The document highlights the importance of continuous improvement and the need for management to shift their focus from departmental optimization to a more holistic approach.

![Philosophy as the Foundation!

• Base management decisions on a long-term philosophy"

The Right Process Will Produce the Right Results!

• Create a continuous process flow to bring problems to the surface"

• Build a culture of stopping to fix problems, to get quality right the first time"

• Standardized tasks and processes are the foundation for continuous improvement and employee

empowerment"

• Use visual control so no problems are hidden"

• Use only reliable, thoroughly tested technology that serves your people and process"

Add Value to the Organization by Developing Your People!

• Grow leaders who thoroughly understand the work, live the philosophy, teach it to others "

• Develop exceptional people and teams to follow your company’s philosophy "

Continuously Solving Root Problems Drive Organizational Learning !

• “Go and see” for yourself to thoroughly understand the situation [aka “Gemba”]!

• Become a learning organization through relentless reflection and continuous improvement

2014 Copyright | Patrick. J. Powers | All Rights Reserved

7

7](https://image.slidesharecdn.com/whatisleaneditedforss-140204004353-phpapp02/85/LEAN-A-Powerful-Introduction-7-320.jpg)