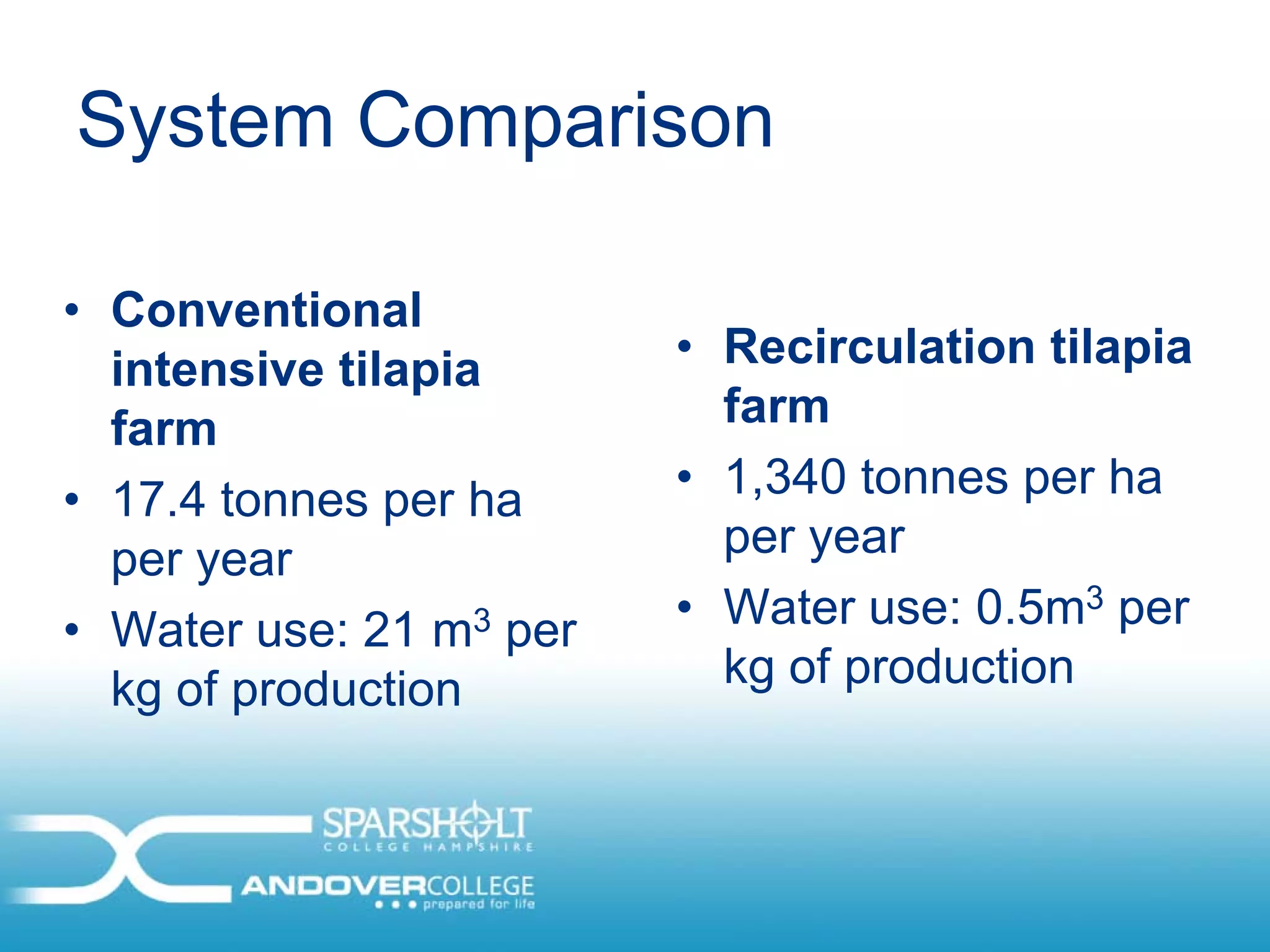

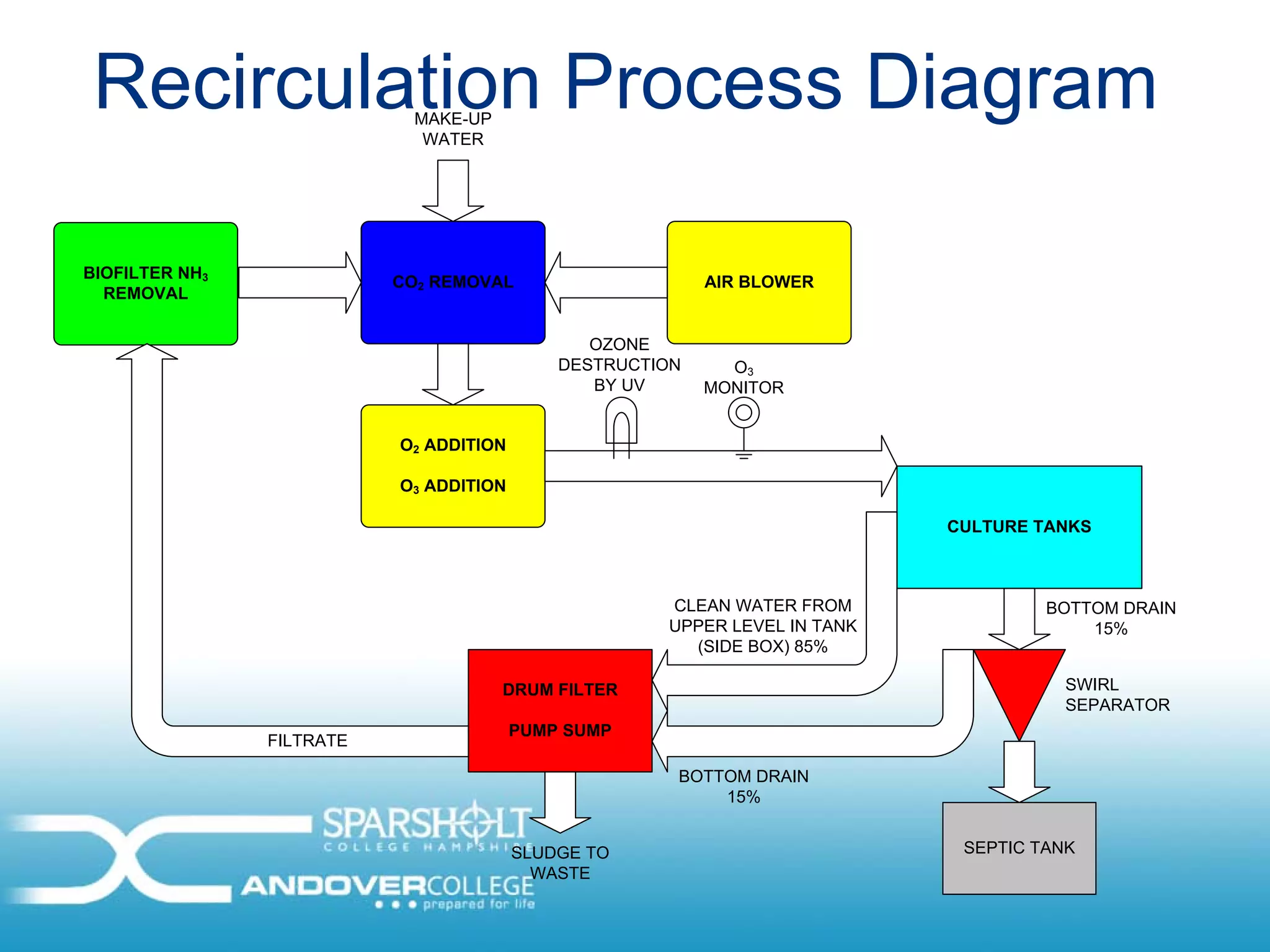

This document discusses recirculation aquaculture systems. It notes that these systems are used worldwide at large scales to intensively produce fish. The key advantages are that they allow precise environmental control, high production capacity, and up to 99% less water usage than conventional aquaculture. However, high initial investment and the complexity of the technology also present challenges. Proper system design, monitoring, staff training and market planning are essential for success.