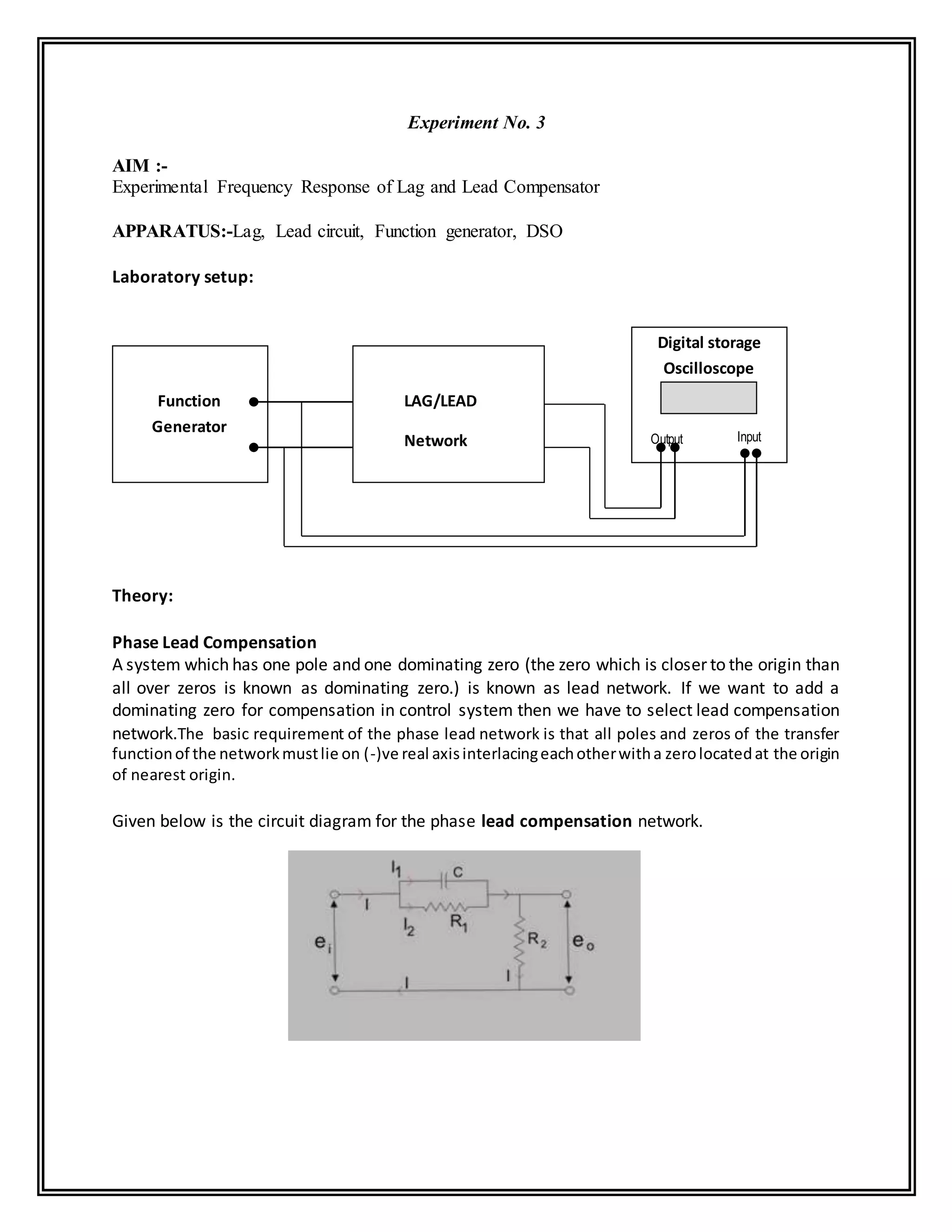

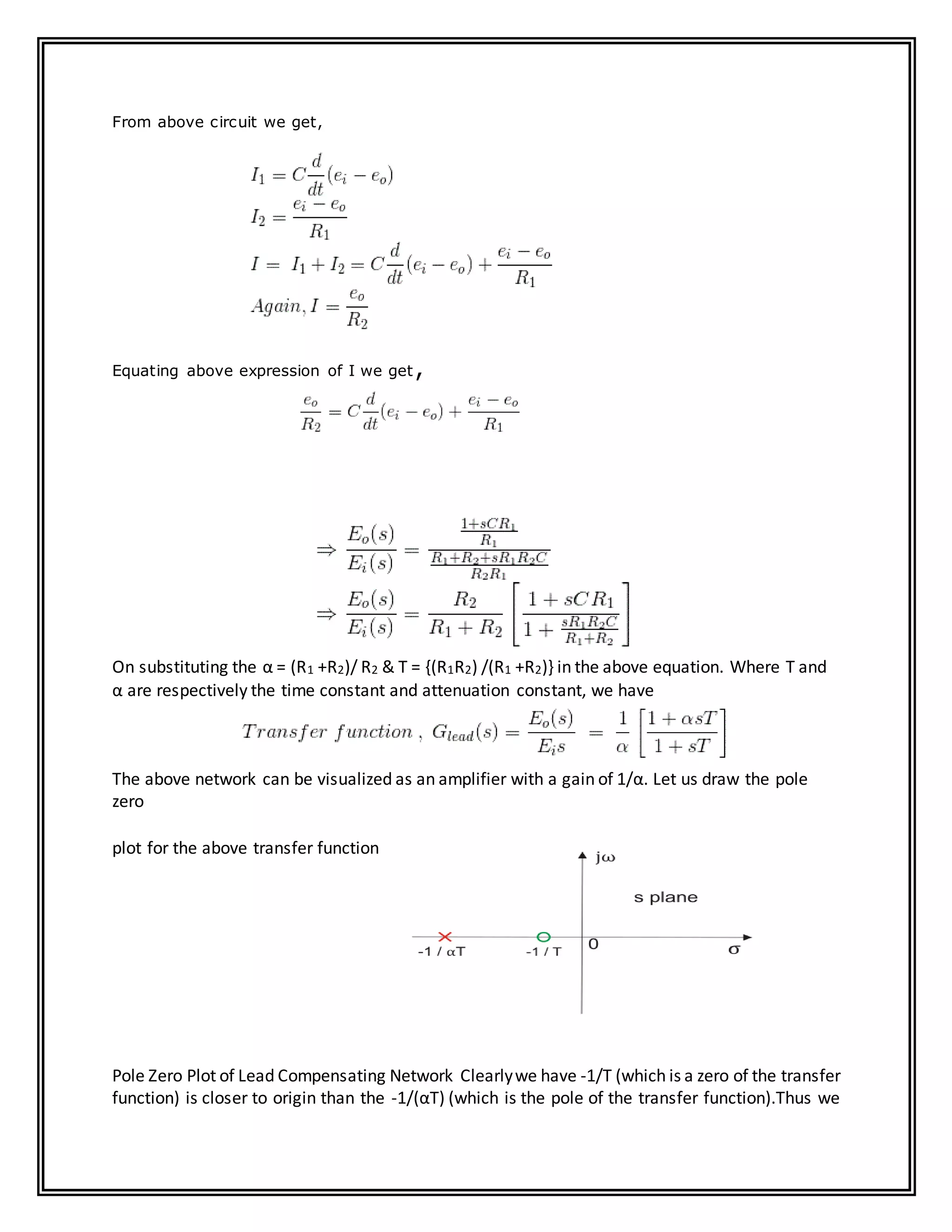

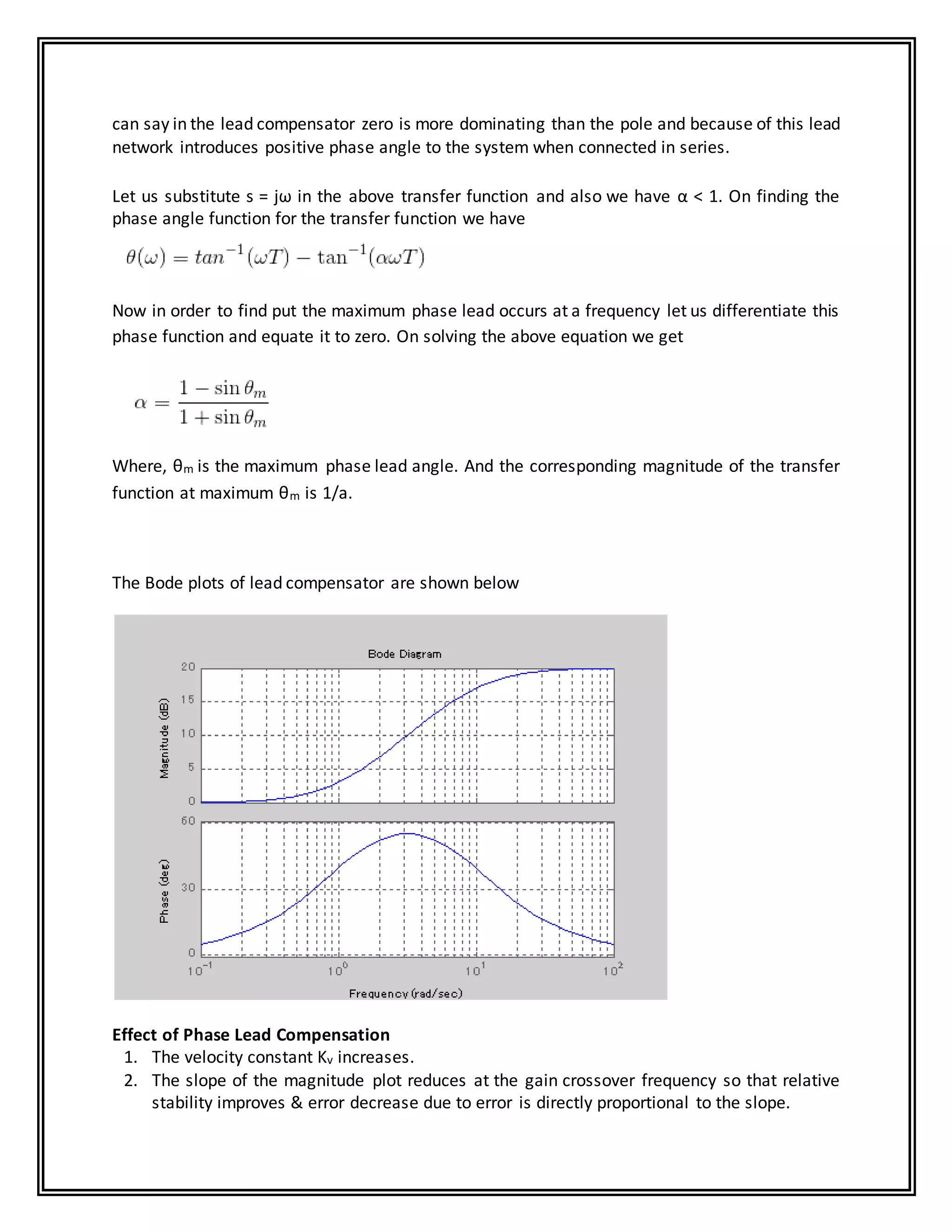

This experiment aims to study the frequency response of lag and lead compensators. A lag compensator circuit contains resistors and capacitors, while a lead compensator contains resistors and an inductor. These compensator circuits are connected to a function generator and digital storage oscilloscope. The transfer functions of the lag and lead compensators are derived. For the lead compensator, the pole-zero plot is drawn to show that the zero is closer to the origin than the pole, introducing positive phase angle. By measuring the output waveforms on the oscilloscope for different compensator circuits, the effect of lag and lead compensation on the frequency response is observed experimentally.

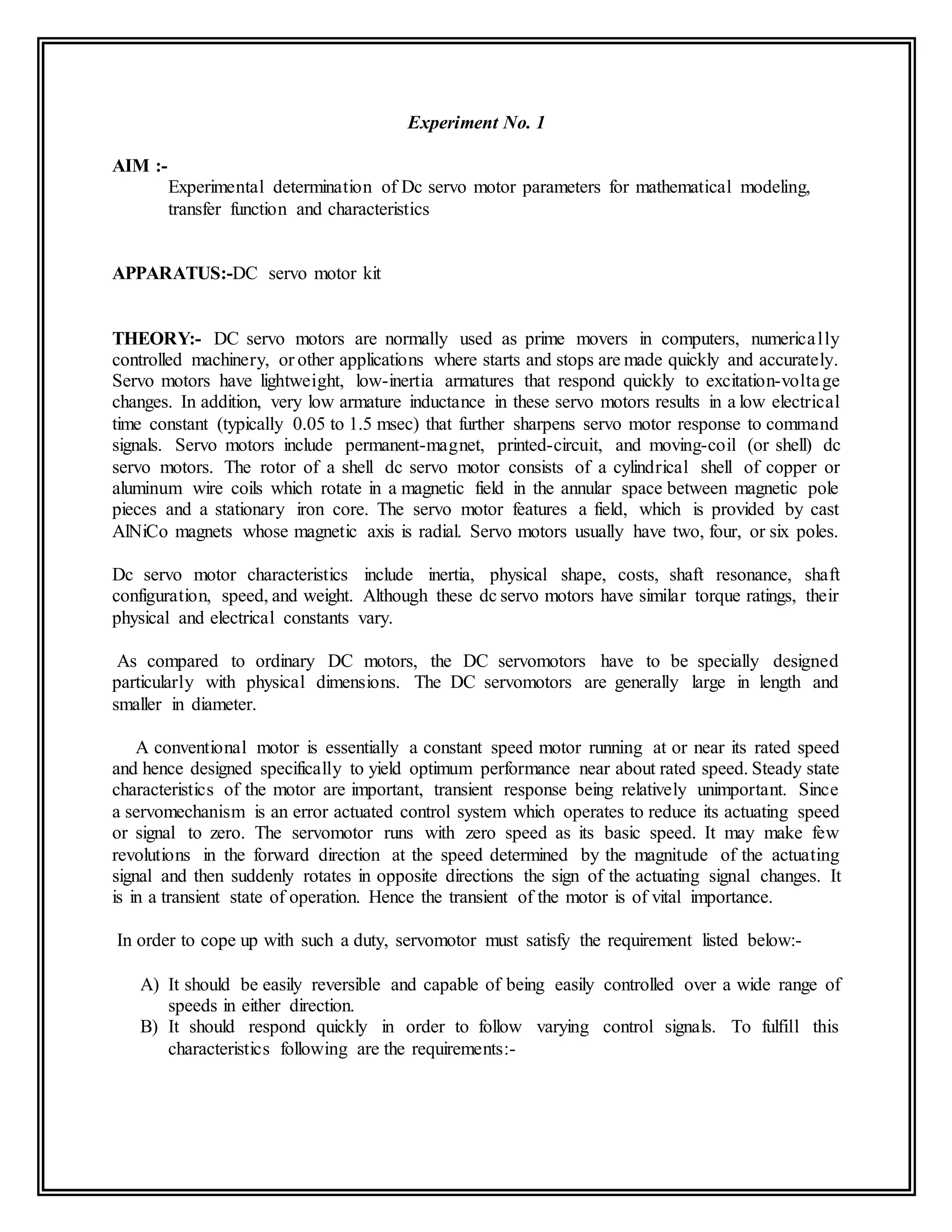

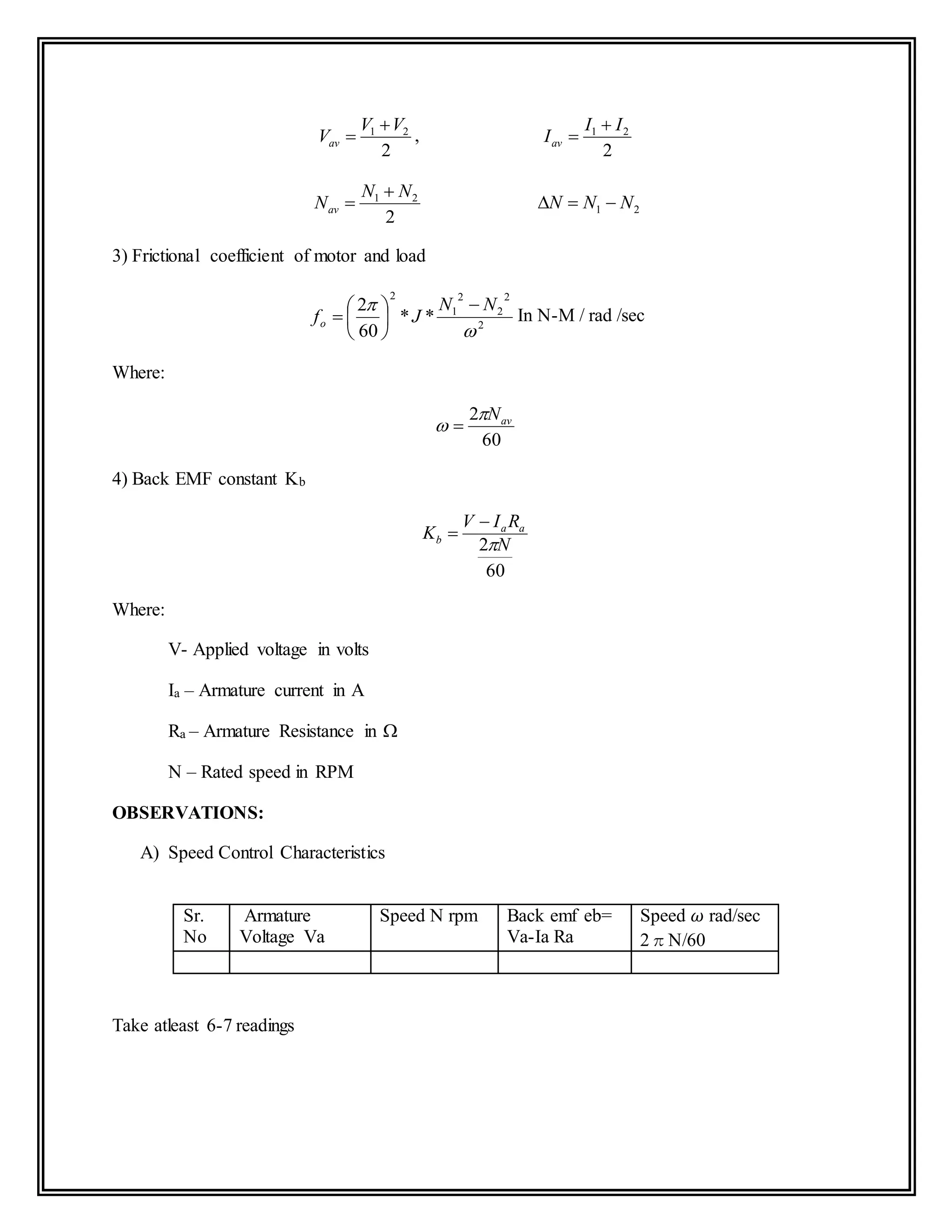

![The Voltage equation of the motor is given by

Va = Eb + Ia Ra + La dIa / dt, taking Laplace transform on both sides,

Va(s) = Eb(s)+ Ia ( Ra+ s La)

Ia(s) = (Va - Eb(s) / ( Ra+ s La)……………………………….(1)

Electromagnetic torque developed is given by;

Te α φ. Ia

Te = Kt. Ia……………………… since φ is constant

Or Tm(s) = Kt. Ia(s)……………………………………….(2)

But the motor torque developed has to satisfy following equation

Tm = J.d2θ /dt2 + f. d θ /dt + TL

Or Te(s) = [ J s2 + f(s) ] θ(s)………………………………..(3)

Equating (2) and (3), we get,

Kt. Ia(s) = [ J s2 + fs ] θ(s)

Kt [ (Va - Eb(s) / (Va - Eb(s) ] = = [ J s2 + fs ] θ(s)…….(4)

But the back emf is proportional to motor speed ,

Eb α Kb . d θ /dt .

Eb = Kb. d θ /dt

where, Kb is back emf constant and expressed as volts / rad. / sec

Or Eb(s) = s.Kb. θ(s)…………………………………………(5)

Sub. (5) in (4 ) and simplification yields,

G(s) =)θ(s) / Va(s) = Kt / ( J s2 + fs ) ( Ra+ s La) s. Kt. Kb ……(6)

Equ. (6) is the required transfer function of](https://image.slidesharecdn.com/labmanual-200824171921/75/Lab-manual-3-2048.jpg)

![Experiment No. 4

AIM :- To study simulation of PID Controller using Matlab.

APPARATUS:-

THEORY:- Controller is a device which when introduced in feedback or forward path of system

controller, the steady state and transient part of device converts the input to the controller to

some otherformthan proportional toerror.Due towhichthe steadystate andtransientresponse

gets improved. In most of the practical systems, controllers input is proportional to error

generated, such systems are called as ‘Proportional error constants.’ To improve the transient

response PID controllers are introduced.

The different types of controllers are:

1) PD – Proportional + Derivative

2) PI – Proportional + Integral

3) PID – Proportional + Integral + Derivative

1) PD Controller- Thisisthe controllerinforwardpath whichchangesthe controllerinputtoPD

of error signal.

Input to controller = 𝑲 𝒑 𝒆( 𝒕) + 𝑲 𝒅

𝒅𝒆(𝒕)

𝒅𝒕

Taking Laplace, we get

Input = KpE(s) + S Kd E(s)

= E(s) [Kp + S Kd]

It has following effect on the system response.

Increases damping ratio

ωn remains unchanged

Reduces peak overshoot

Reduces settling time

In general it improves the transient part and not the steady state part. The type of

the system and steady state error remains unchanged.

2) PI Controller- This is the controller in forward path which changes the controller input to PI

of error signal.

Input to controller = 𝑲 𝒑 𝒆( 𝒕) + 𝑲𝒊 ∫ 𝒆( 𝒕) 𝒅𝒕

Taking Laplace, we get

Input = KpE(s) + S Ki

𝑬(𝒔)

𝒔

= E(s) [ Kp +

𝑲 𝒊

𝑺

]](https://image.slidesharecdn.com/labmanual-200824171921/75/Lab-manual-19-2048.jpg)

![Open-loop step response: Let's first view the open-loopstep response.

num=1;

den=[1 10 20];

plant=tf(num,den);

step(plant)

MATLAB command window should give you the plot shown below.

The DC gain of the plant transfer function is 1/20, so 0.05 is the final value of the output to a unit

step input. This corresponds to the steady-state error of 0.95, quite large indeed.Furthermore, the

rise time is about one second, and the settling time is about 1.5 seconds. Let's design a controller

that will reduce the rise time, reduce the settling time,and eliminates the steady-state error.

Proportional control:

The closed-looptransfer function of the above system with a proportional controller is:](https://image.slidesharecdn.com/labmanual-200824171921/75/Lab-manual-21-2048.jpg)

![Let the proportional gain (KP) equal 300:

Kp=300;

contr=Kp;

sys_cl=feedback(contr*plant,1);

t=0:0.01:2;

step(sys_cl,t)

The above plot shows that the proportional controller reduced both the rise time and the steady-

state error, increased the overshoot, and decreased the settling time by small amount.

Proportional-Derivative control:

The closed-looptransfer function of the given system with a PD controller is:

Let KP equal 300 as before and let KD equal 10.

Kp=300;

Kd=10;

contr=tf([Kd Kp],1);

sys_cl=feedback(contr*plant,1);

t=0:0.01:2;](https://image.slidesharecdn.com/labmanual-200824171921/75/Lab-manual-22-2048.jpg)

![step(sys_cl,t)

This plot shows that the derivative controller reduced both the overshoot and the settling time, and

had a small effect on the rise time and the steady-state error.

Proportional-Integral control:

Before going into a PID control, let's take a look at a PI control. For the givensystem, the closed-

loop transfer function with a PI control is:

Let's reduce the KP to 30, and let KI equal 70.

Kp=30;

Ki=70;

contr=tf([Kp Ki],[1 0]);

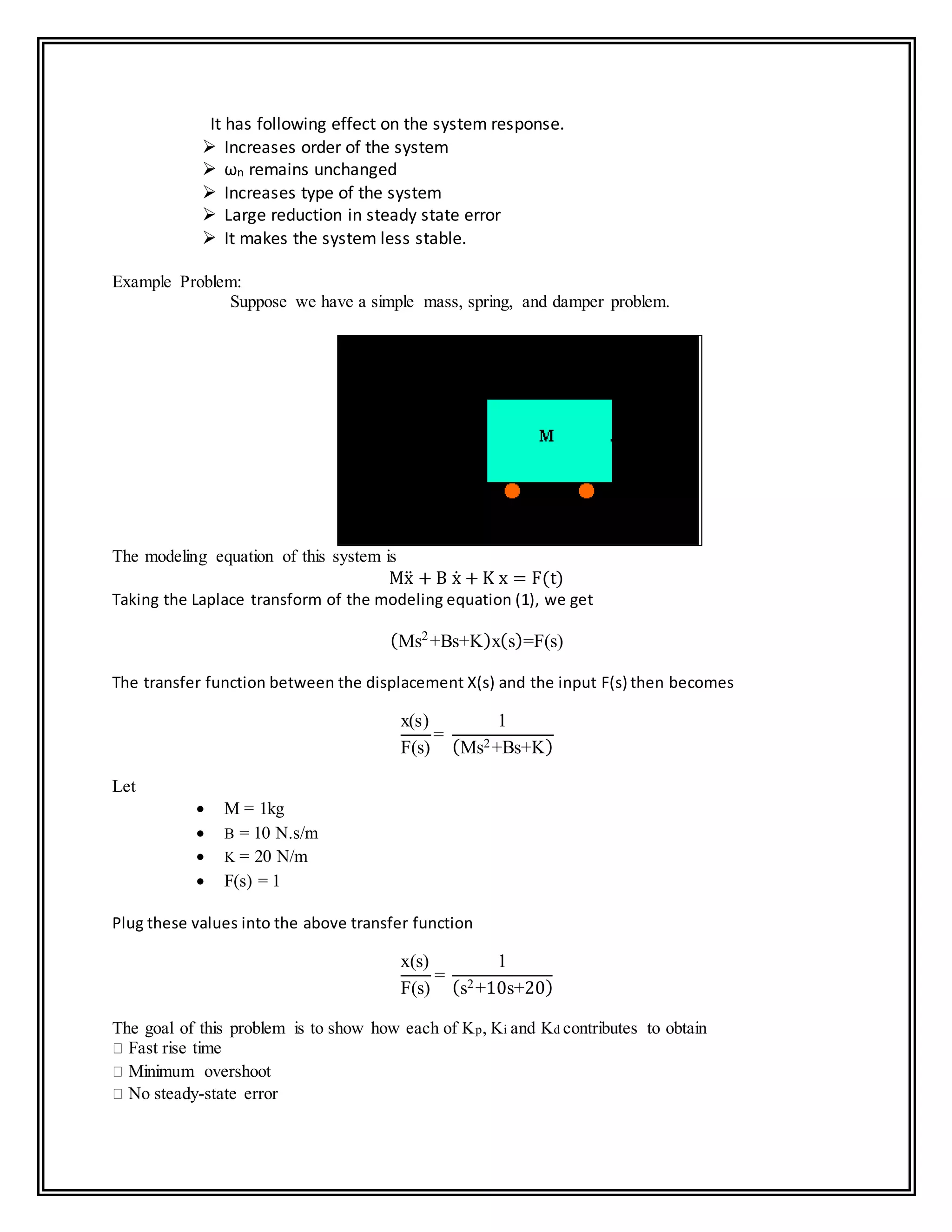

sys_cl=feedback(contr*plant,1);

t=0:0.01:2;](https://image.slidesharecdn.com/labmanual-200824171921/75/Lab-manual-23-2048.jpg)

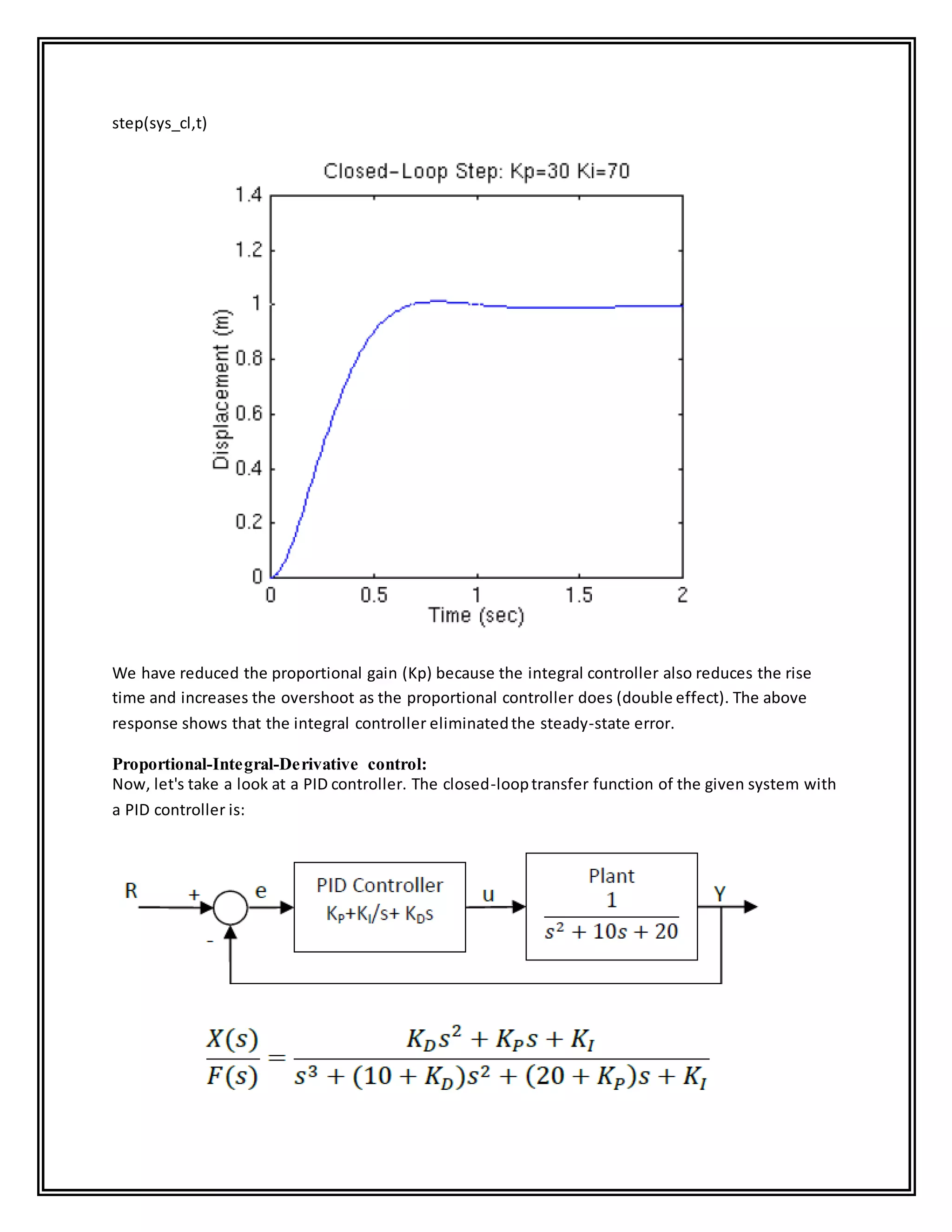

![After several trial and error runs, the gains Kp=350, Ki=300, and Kd=50 provided the desired

response. To confirm, enter the following commands to an m-file and run it in the command window.

You should get the following step response.

Kp=350;

Ki=300;

Kd=50;

contr=tf([Kd Kp Ki],[1 0]);

sys_cl=feedback(contr*plant,1);

t=0:0.01:2;

step(sys_cl,t)

Now, we have obtained a closed-loop system with no overshoot, fast rise time, and no steady-state

error.

The characteristics of P, I, and D controllers:

The proportional controller (KP) will have the effect of reducing the rise time and will reduce, but

never eliminate, the steady state error. An integral controller (KI) will have the effect of eliminating

the steady state error, but it may make the transient response worse. A derivative control (KD) will

have the effect of increasing the stability of the system, reducing the overshoot and improving the

transient response.

Effect of each controller KP,KI and KD on the closed-loop system are summarized below](https://image.slidesharecdn.com/labmanual-200824171921/75/Lab-manual-25-2048.jpg)