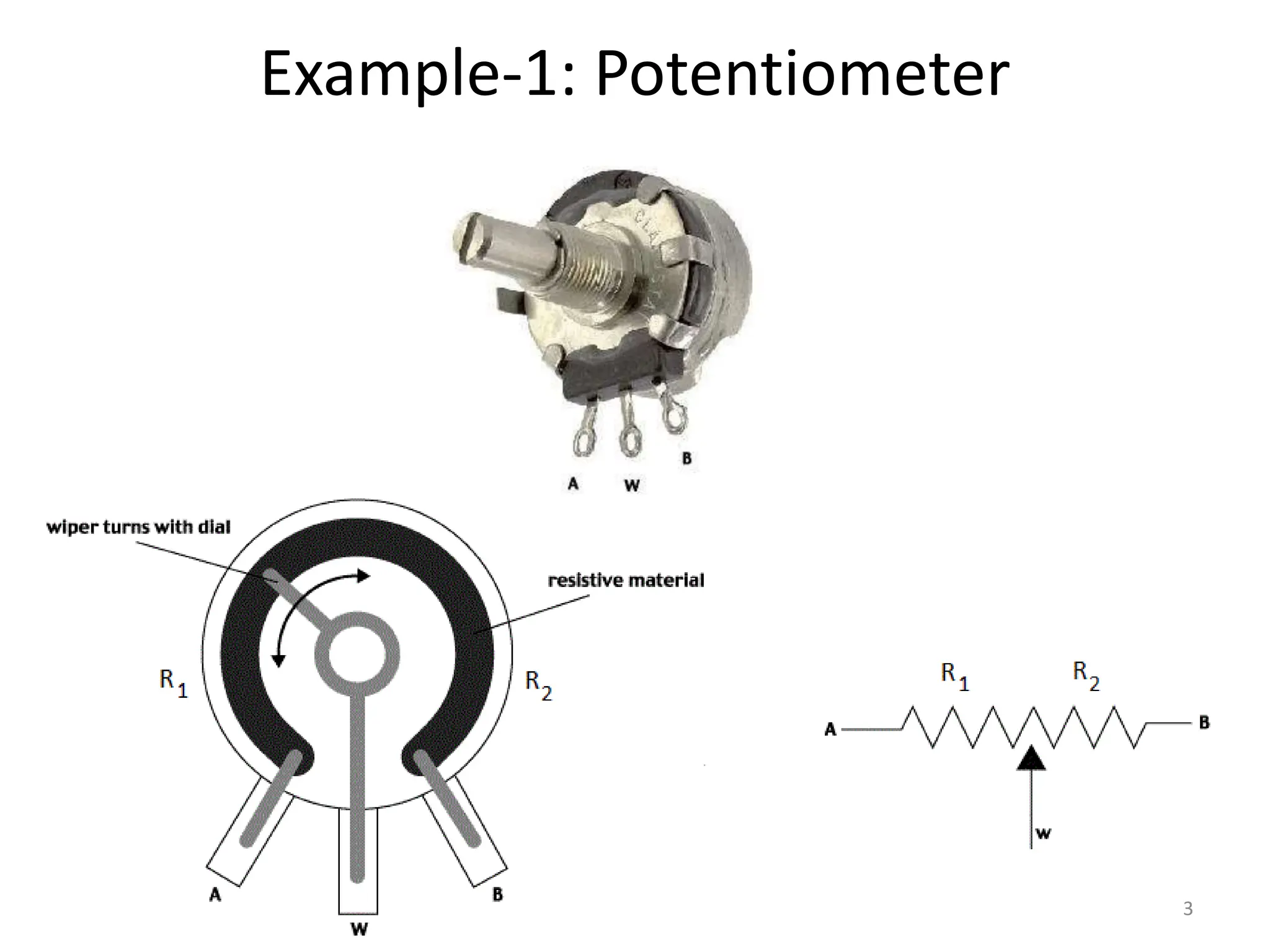

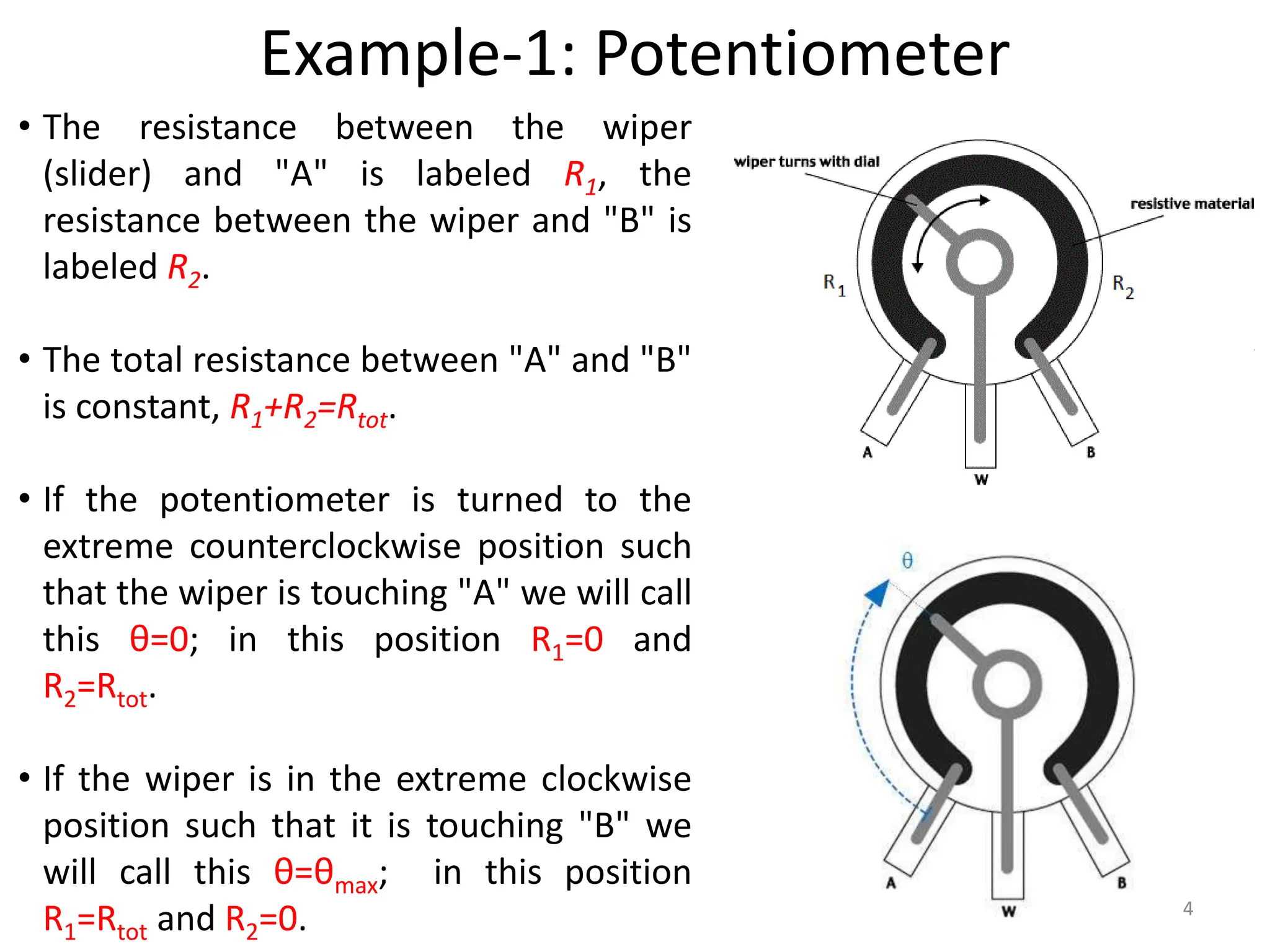

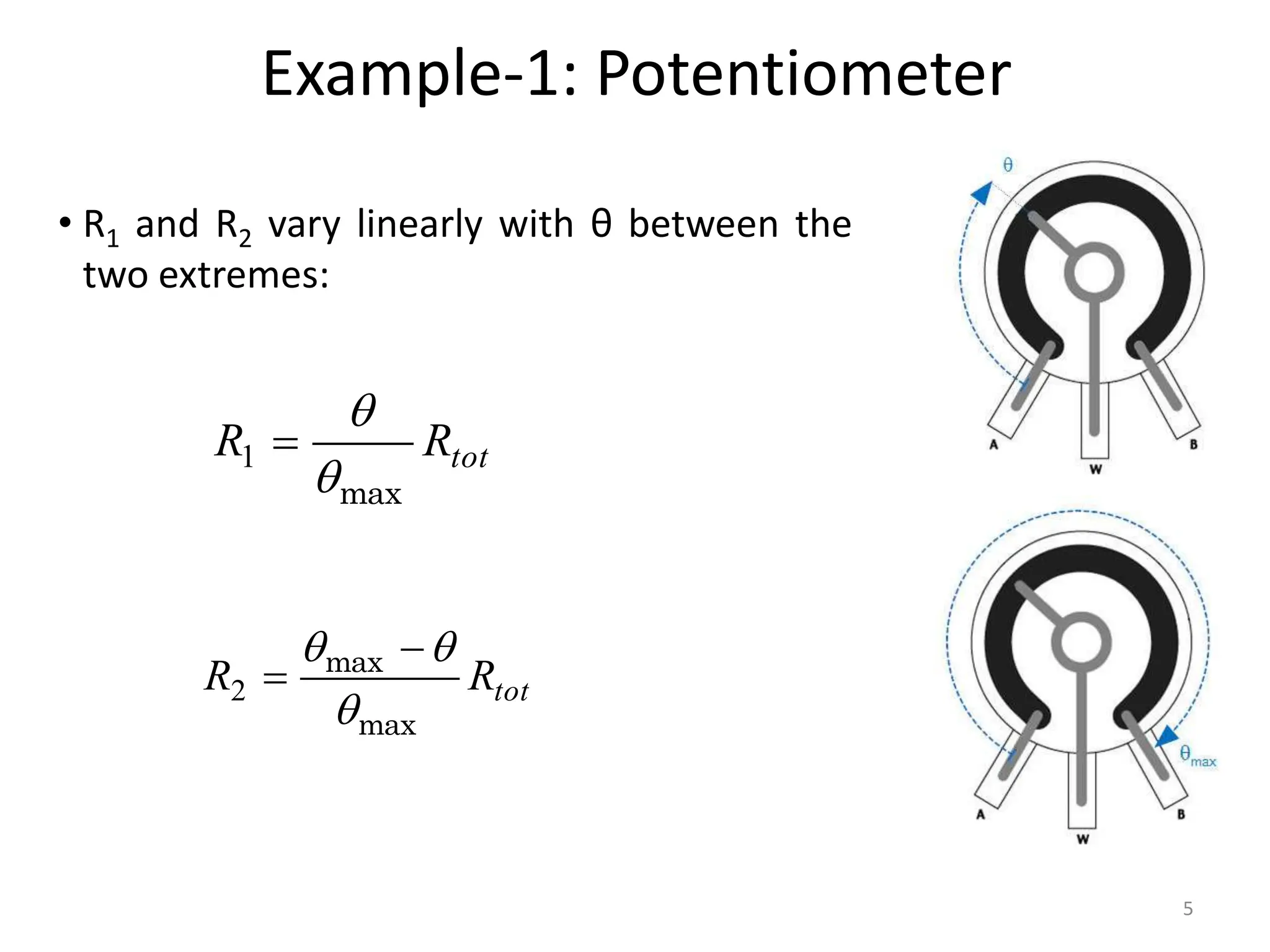

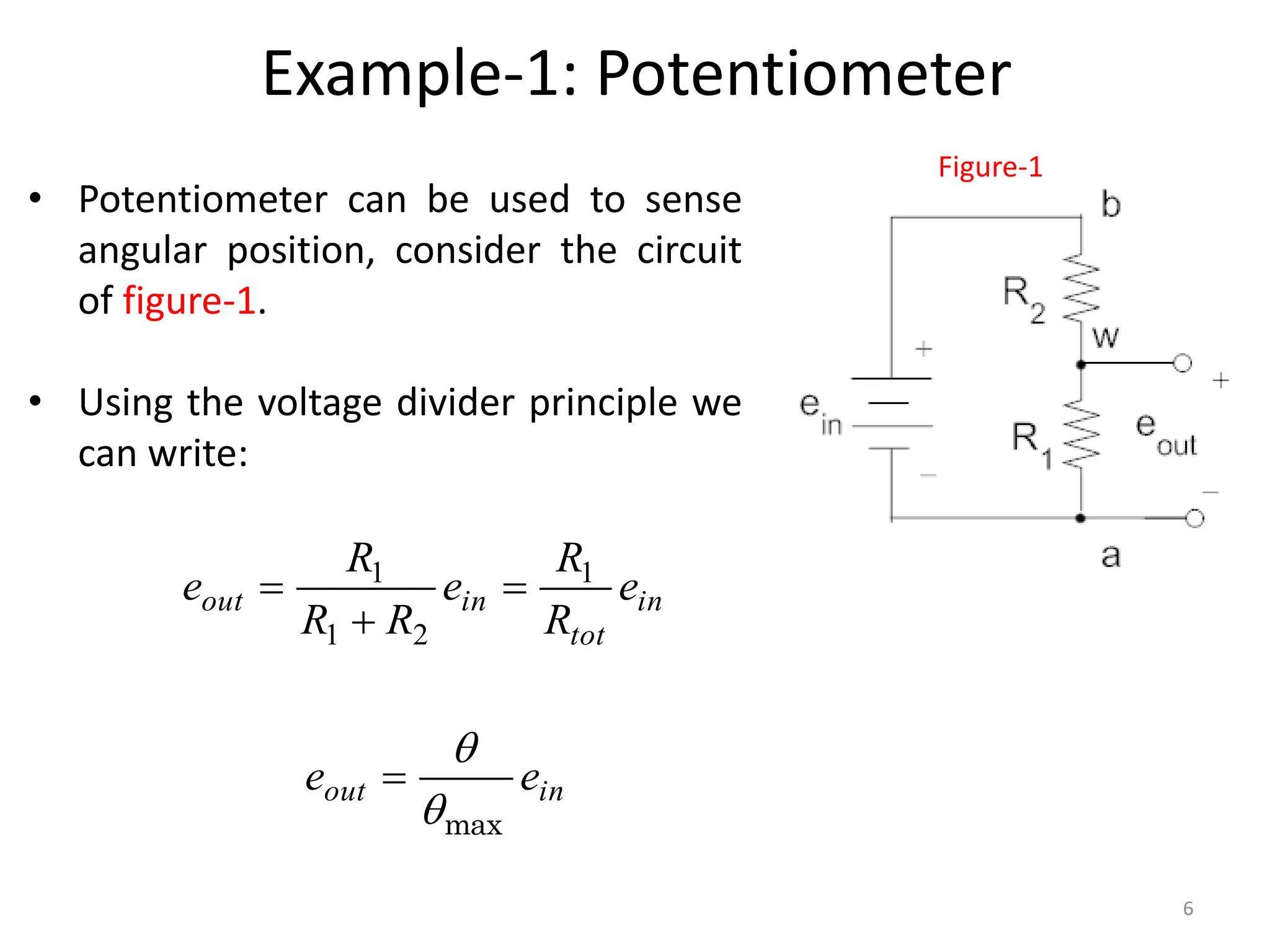

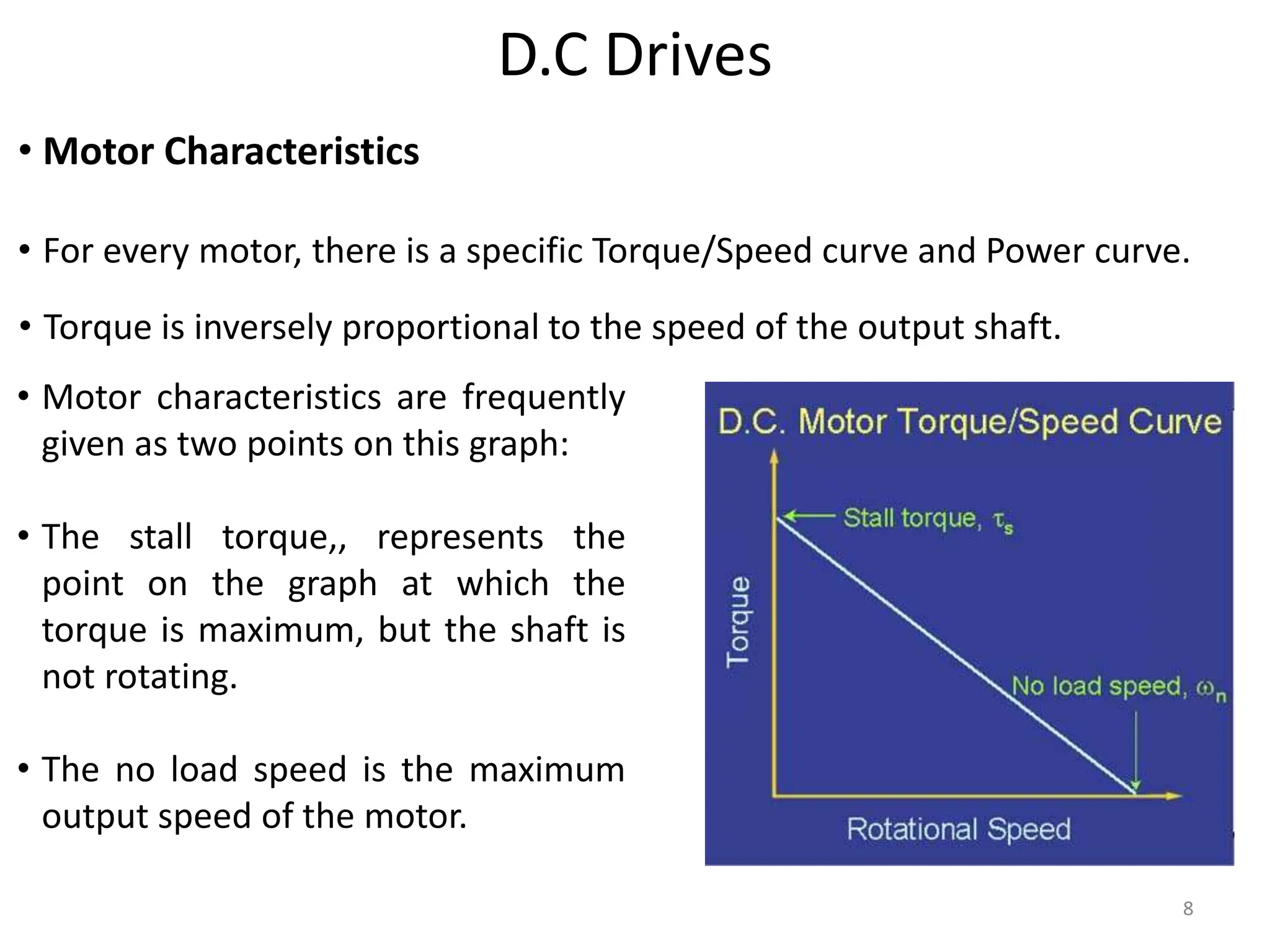

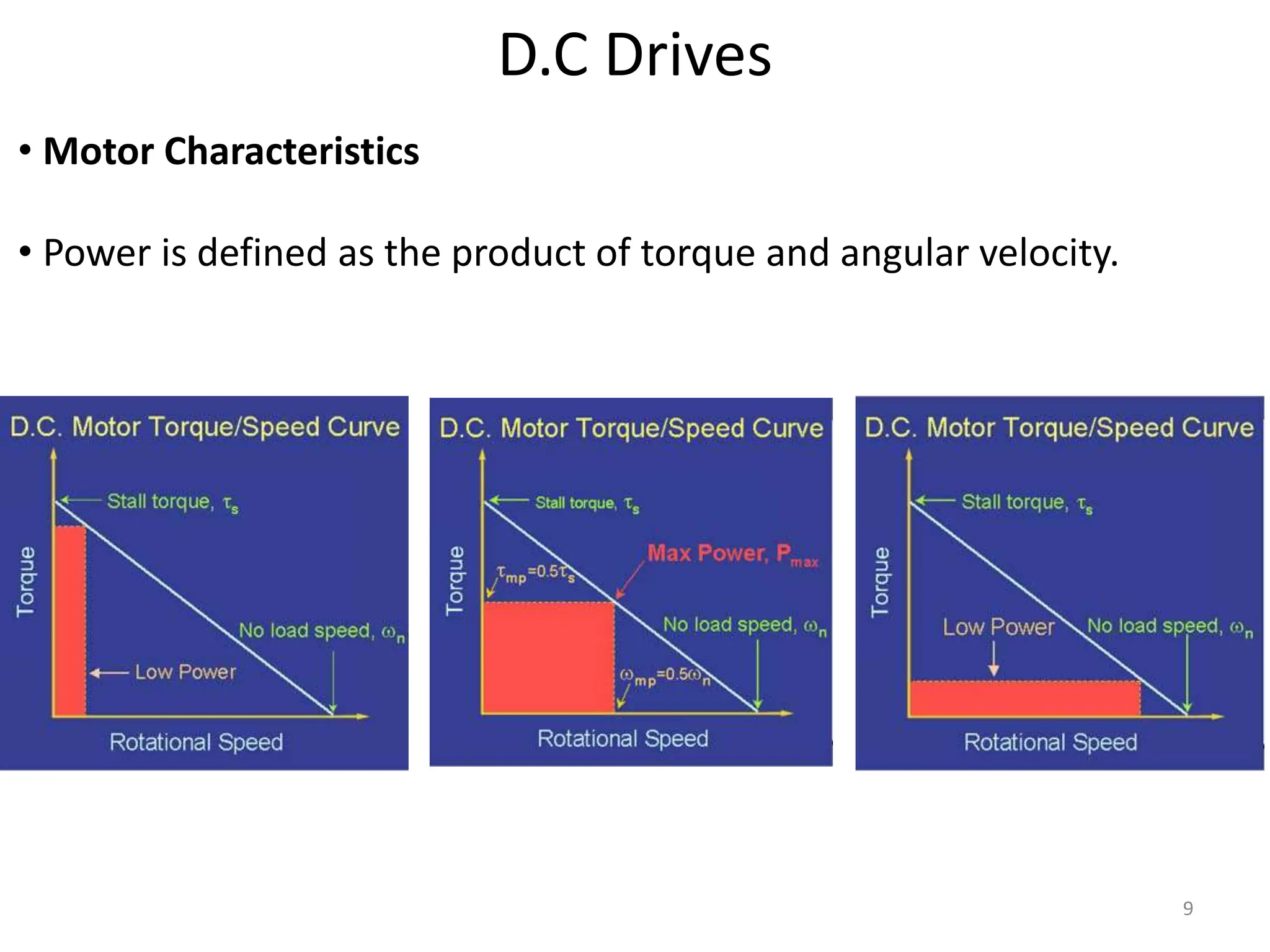

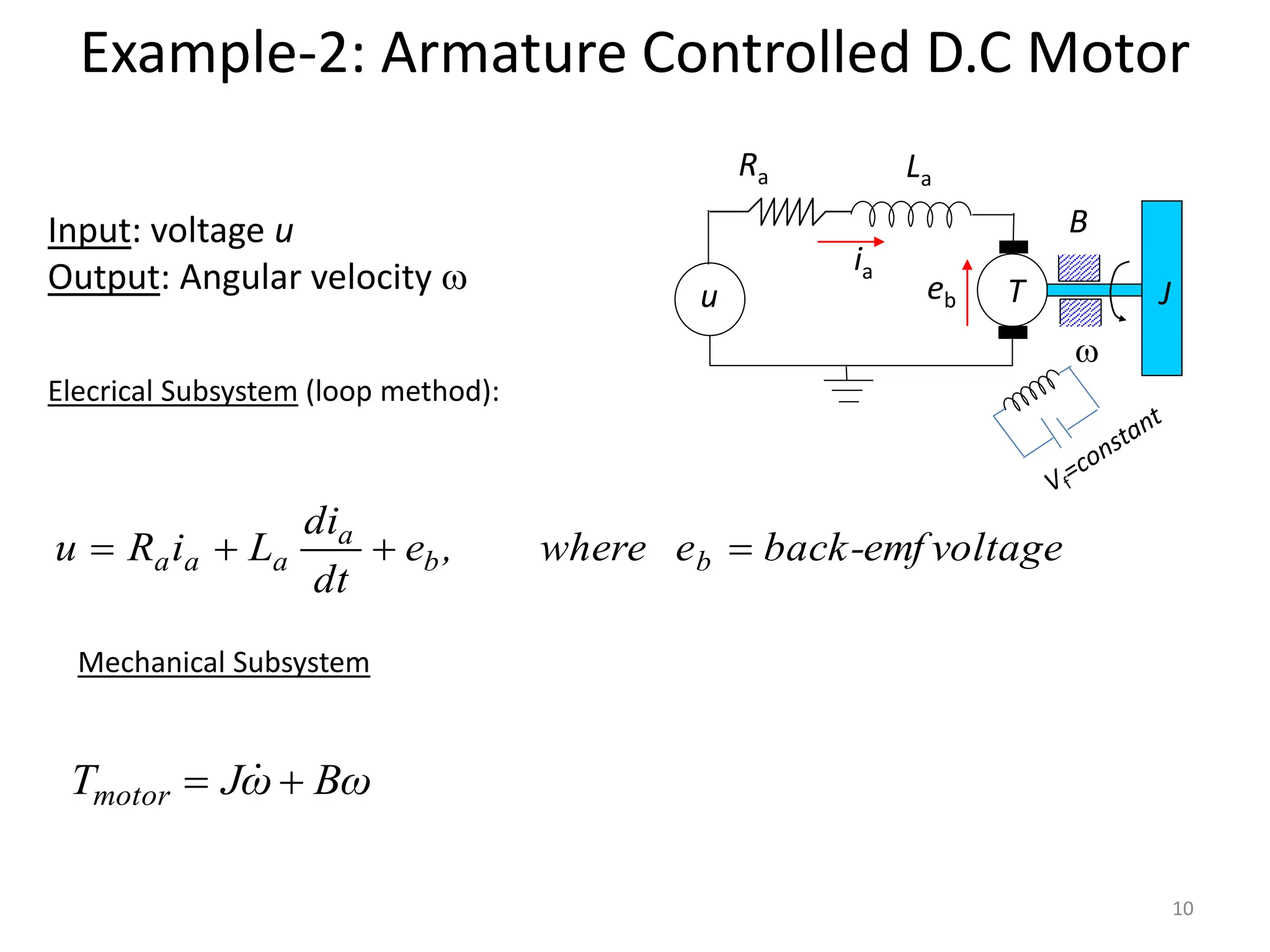

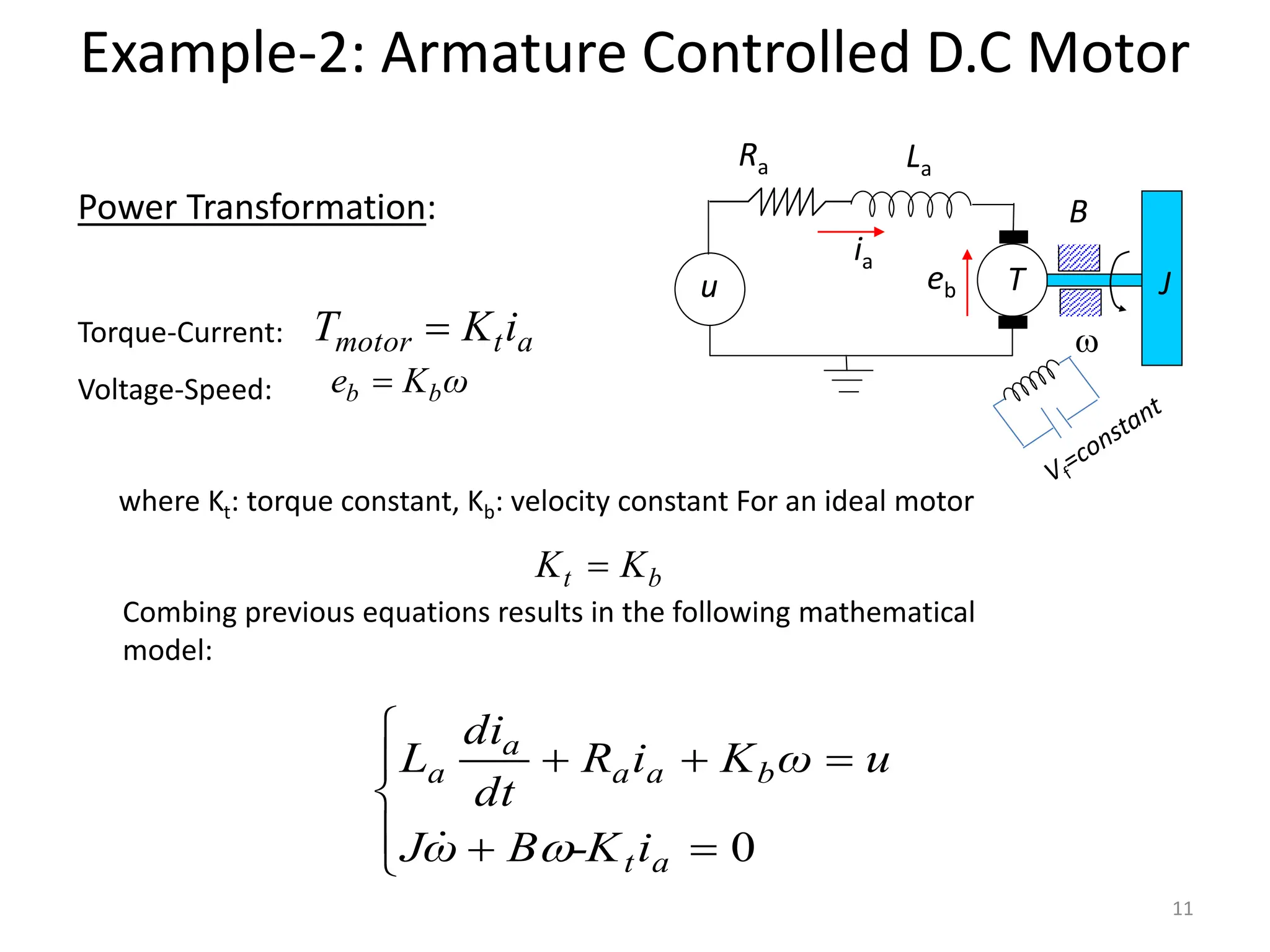

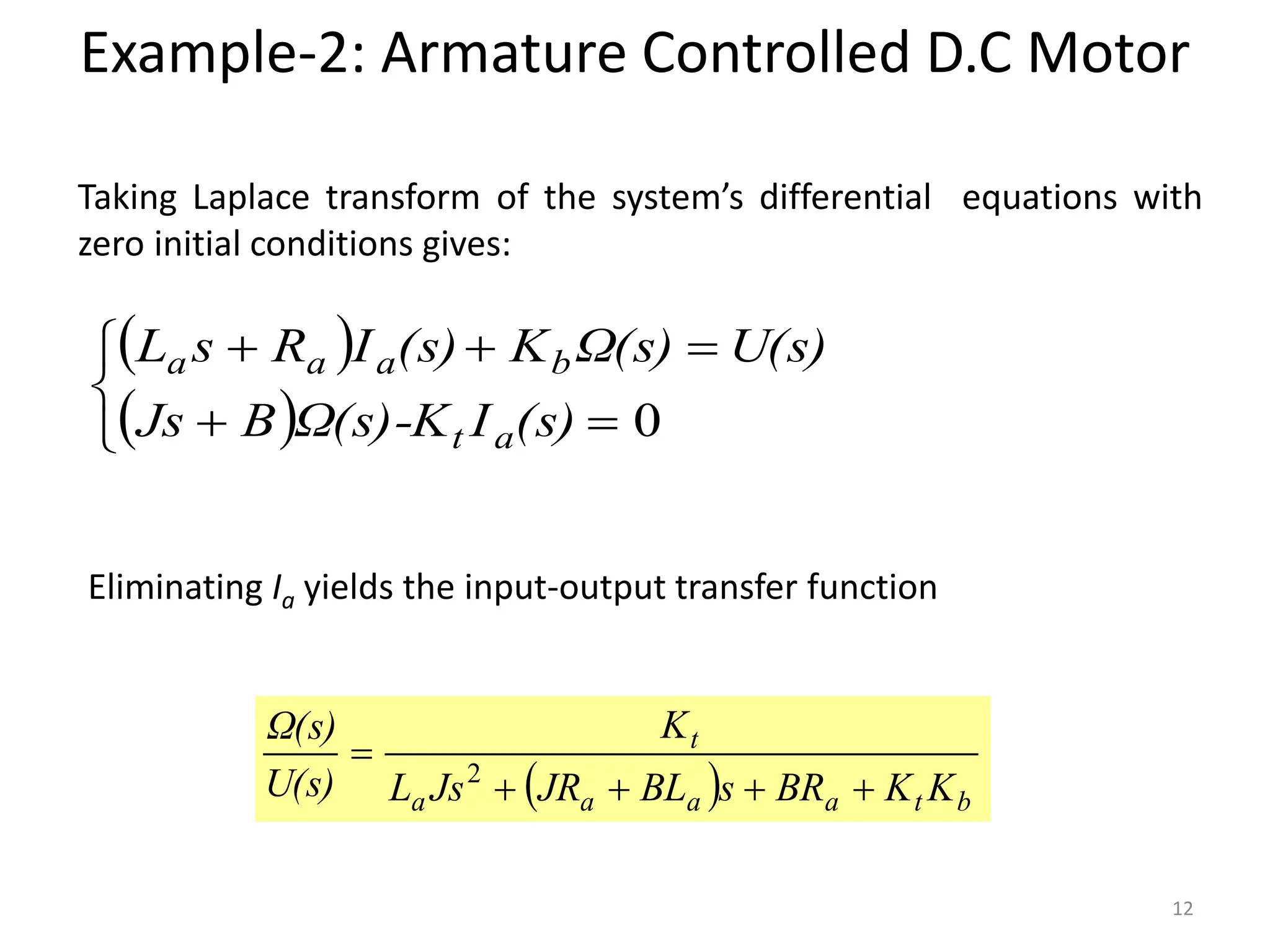

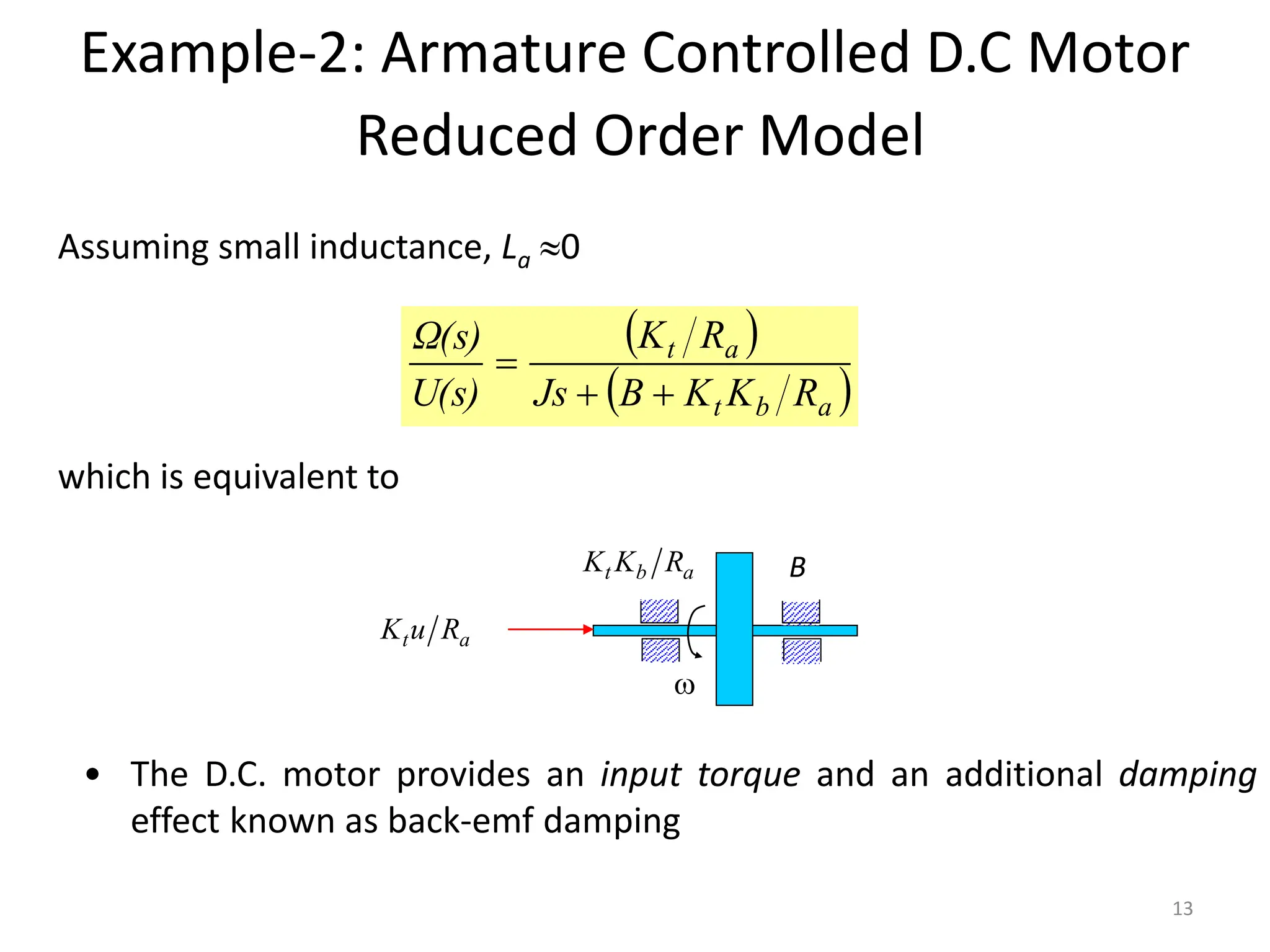

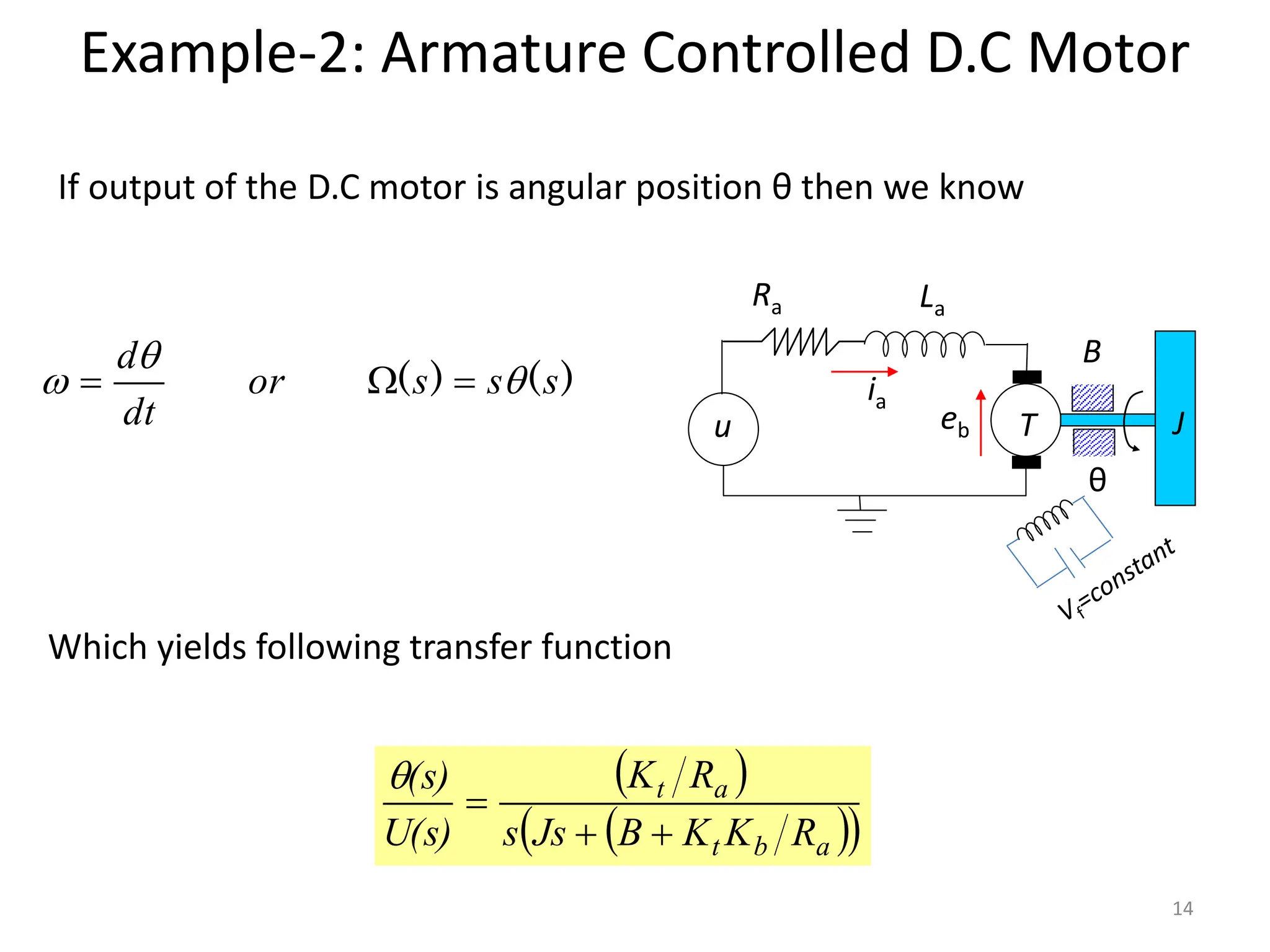

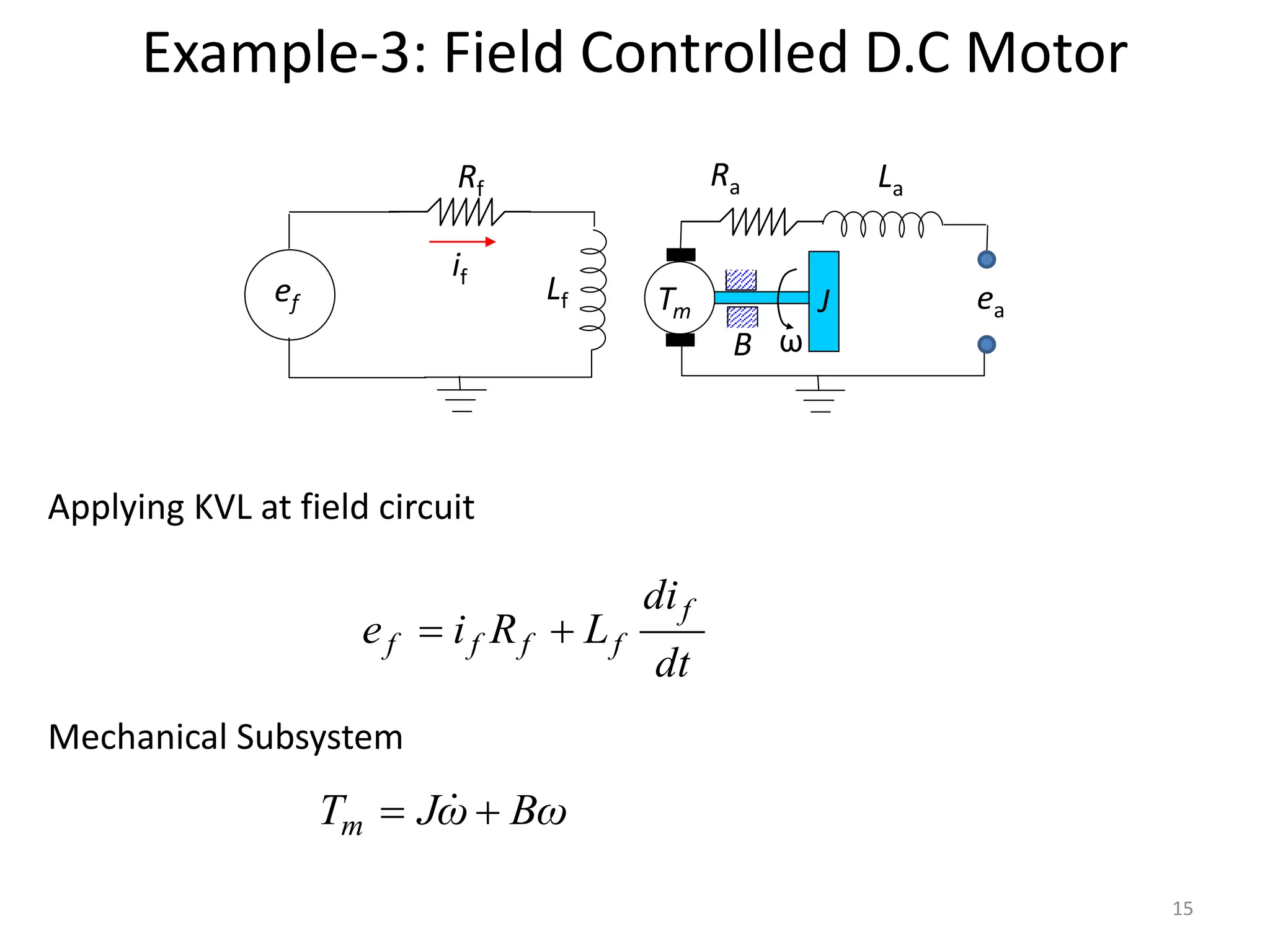

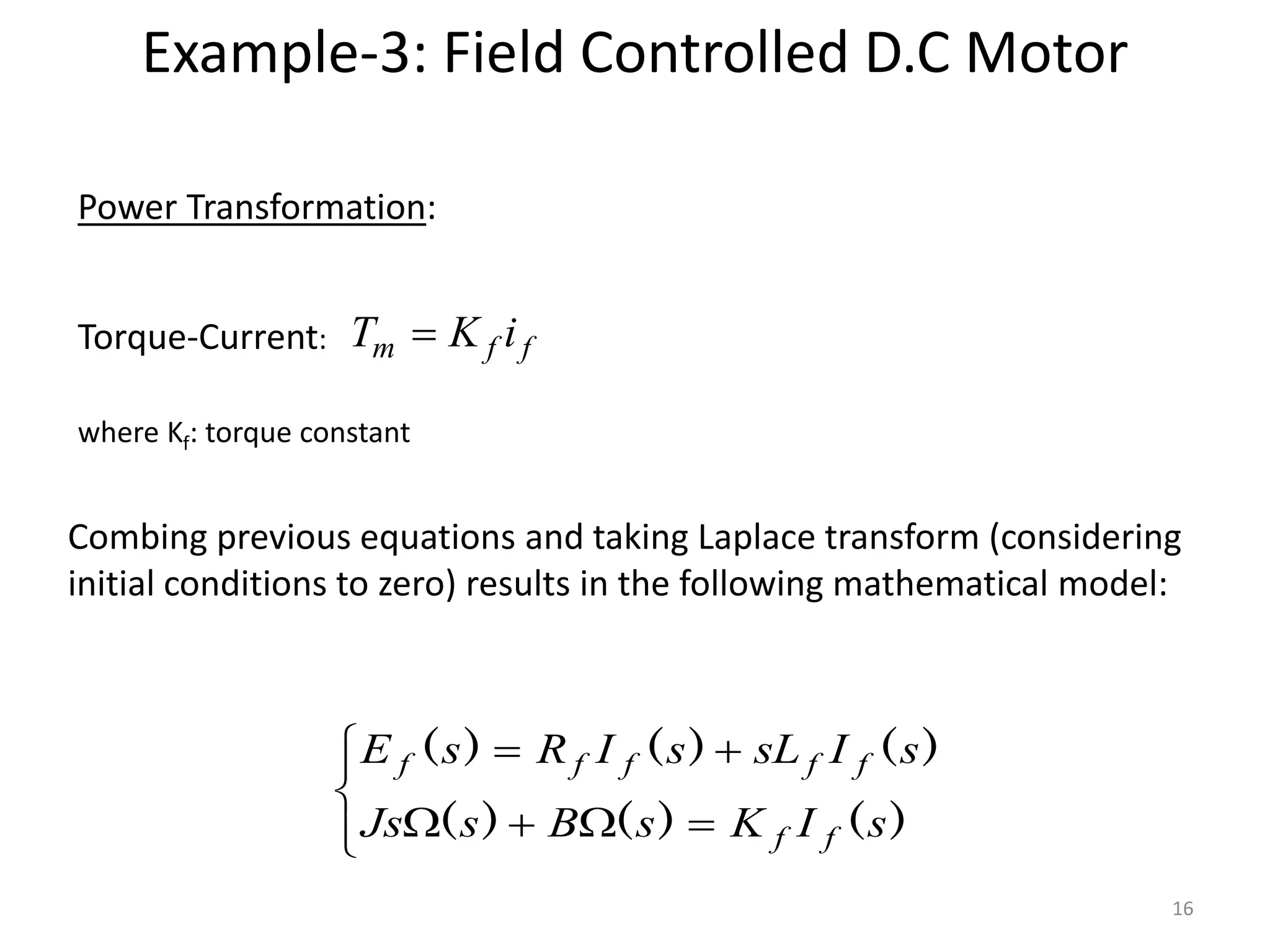

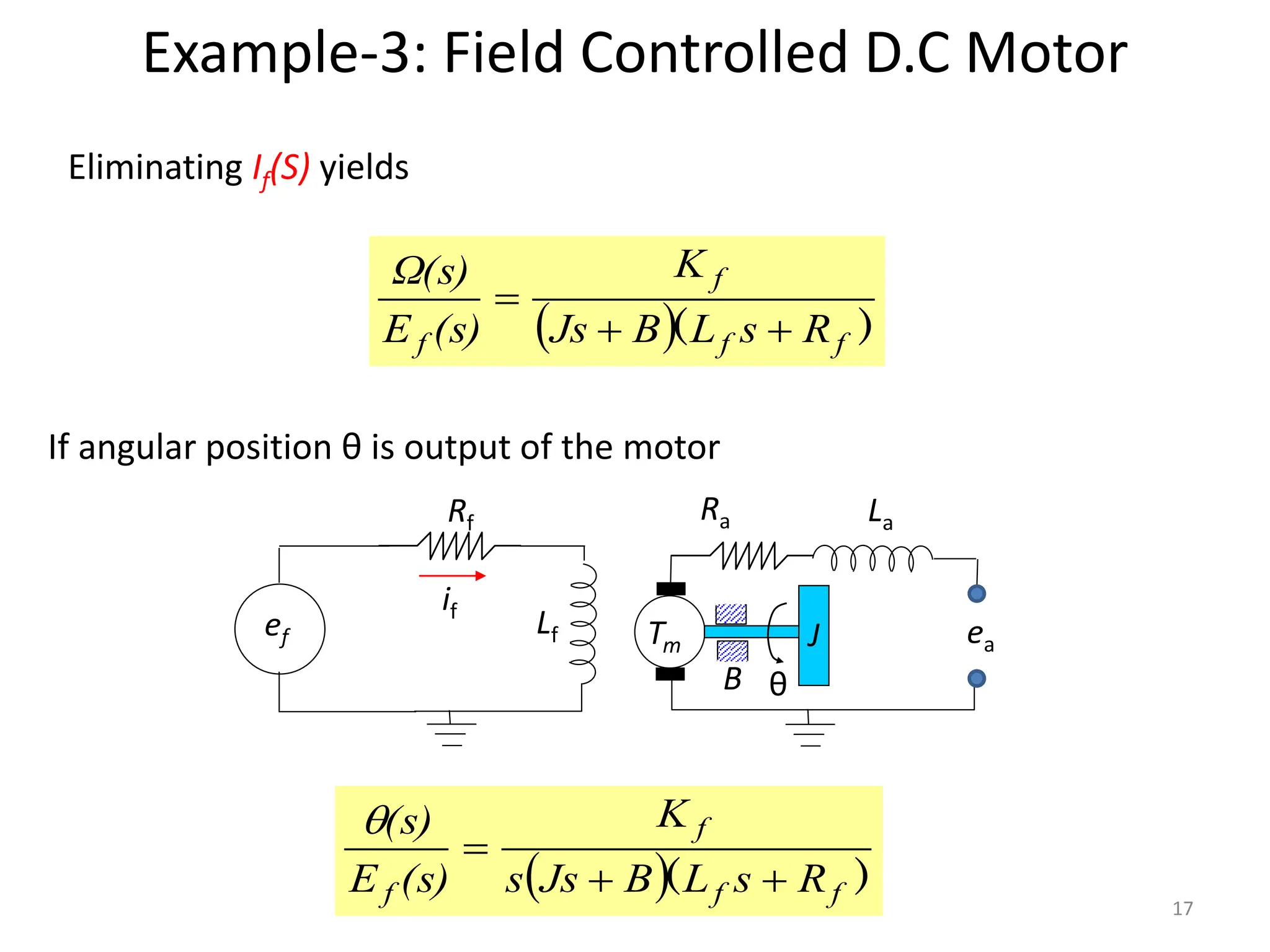

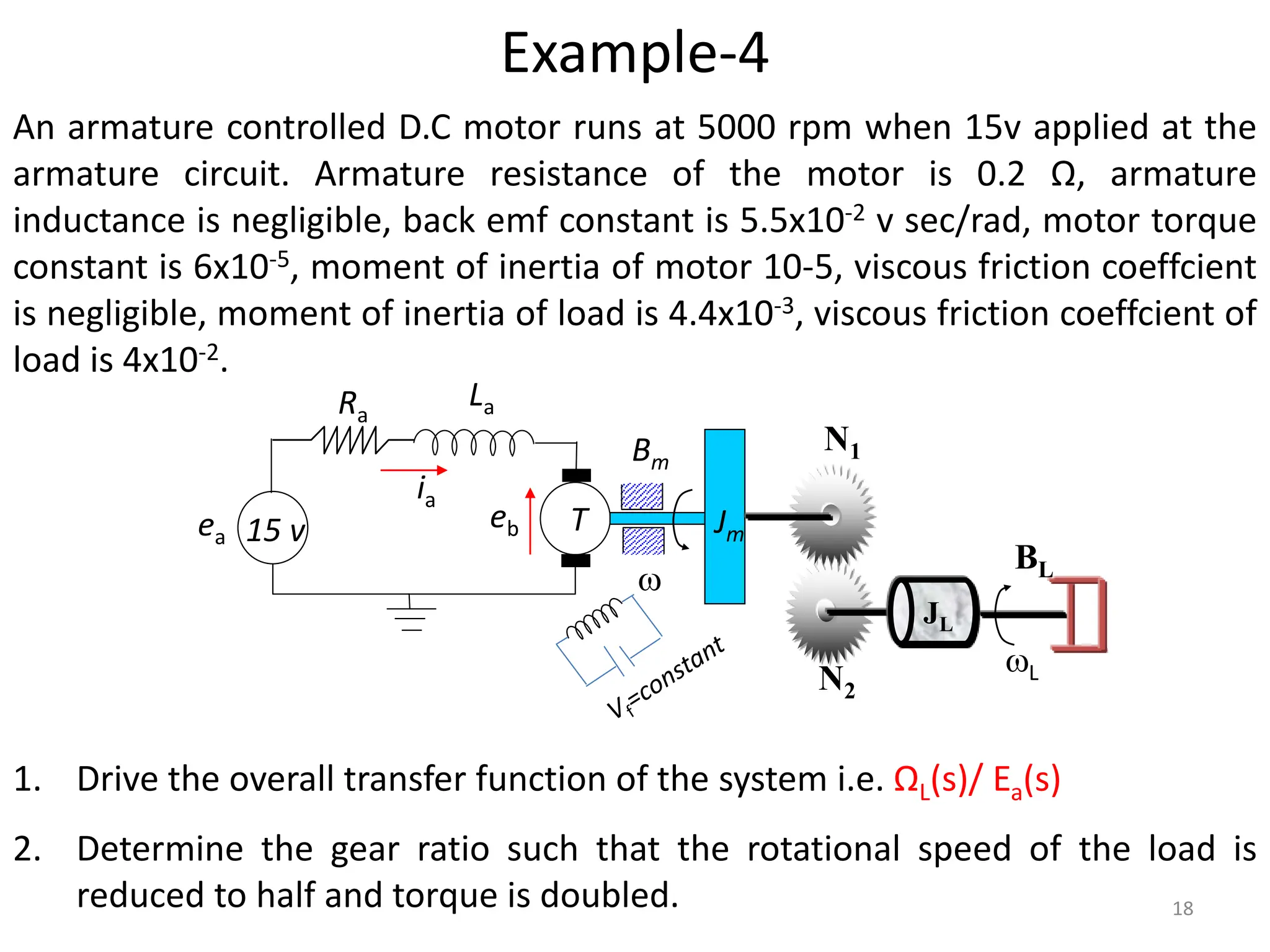

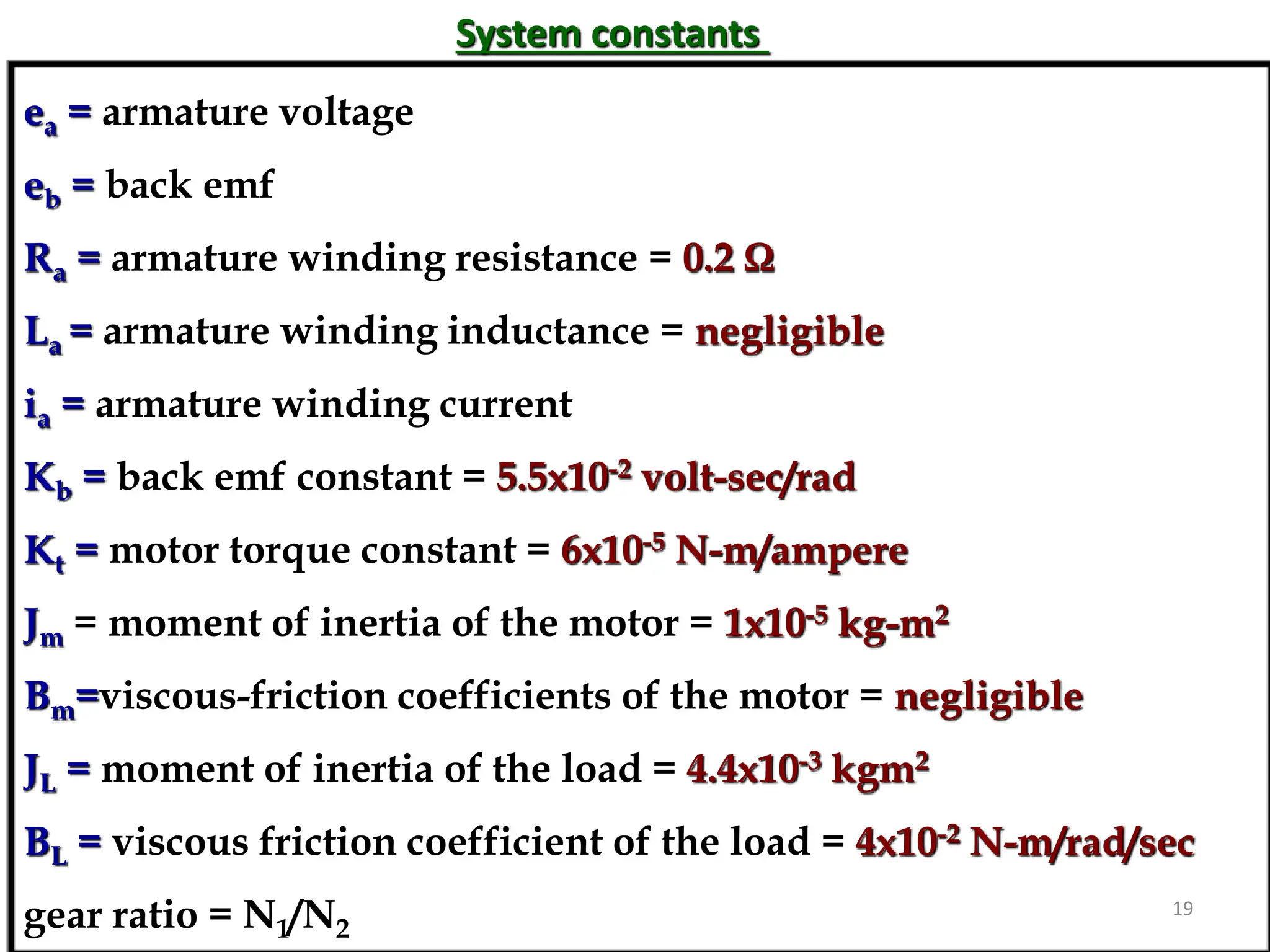

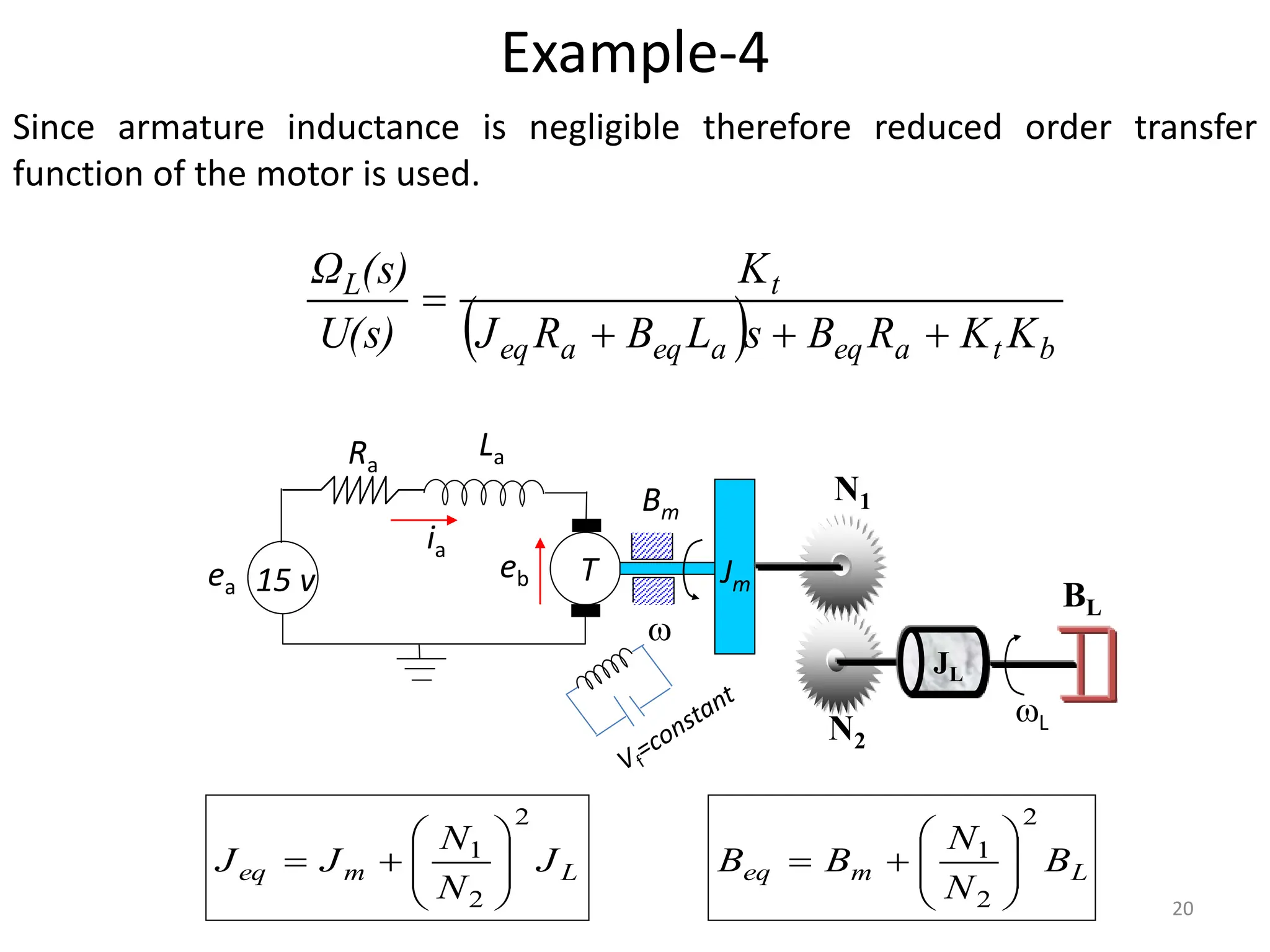

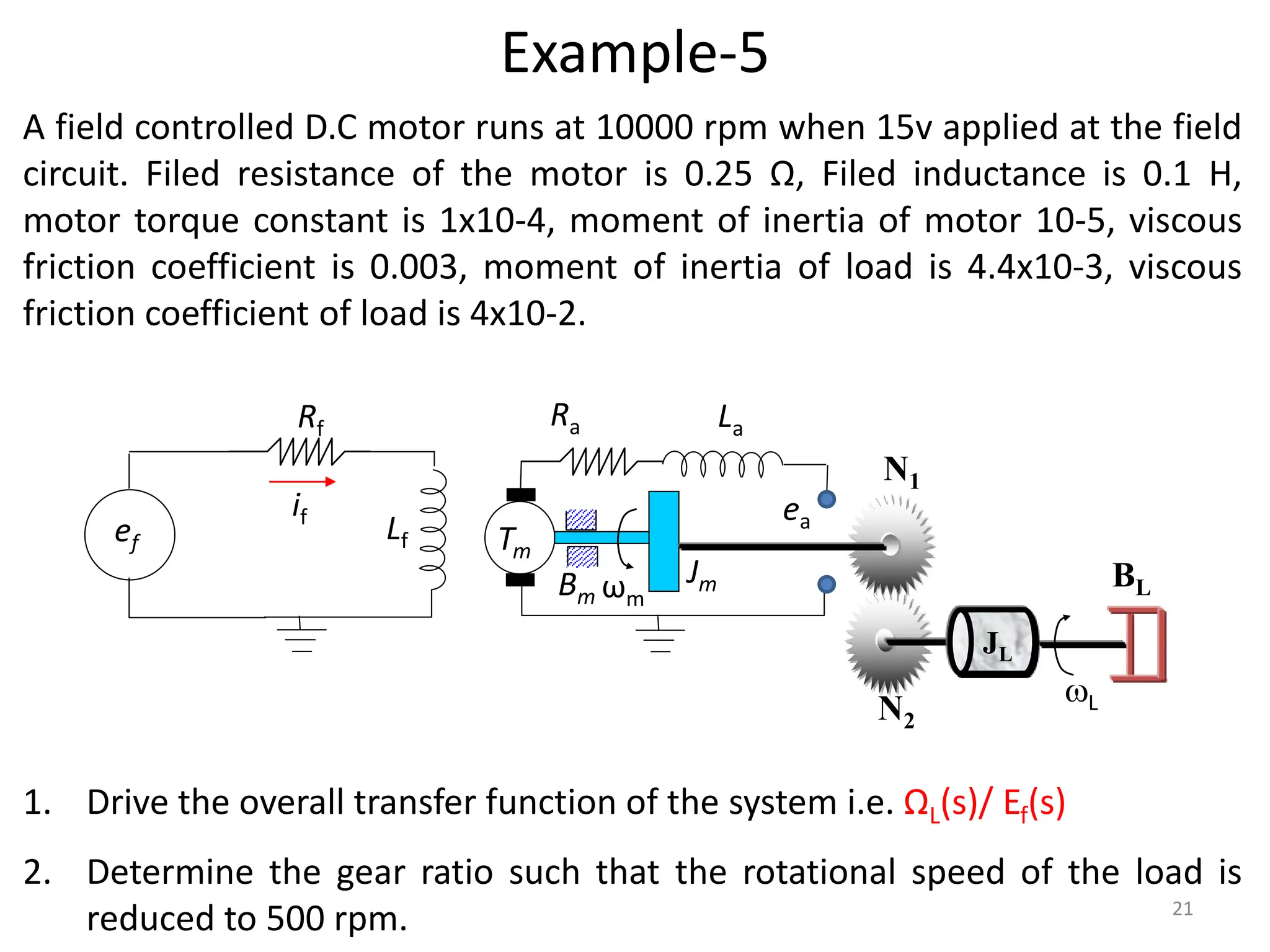

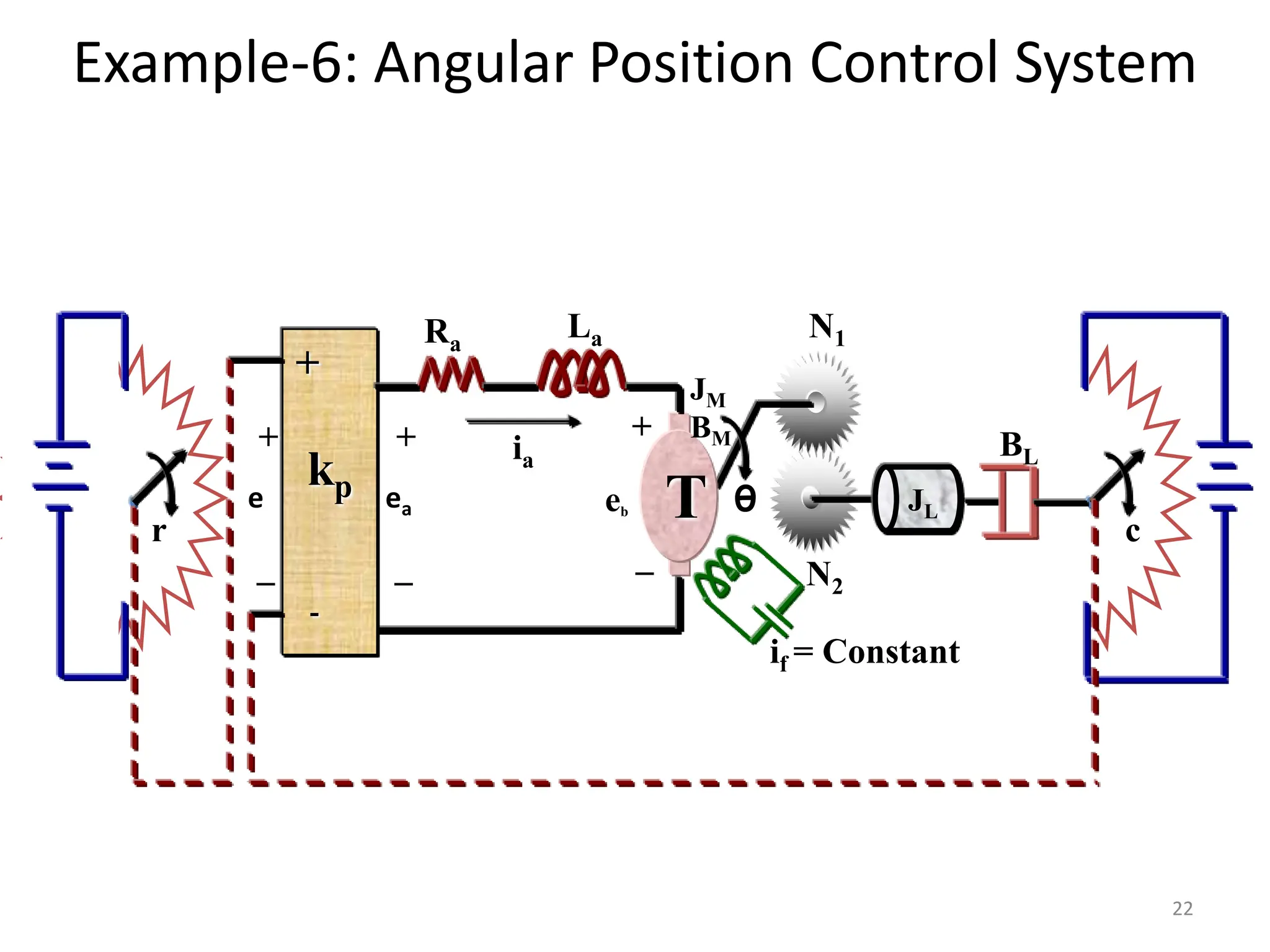

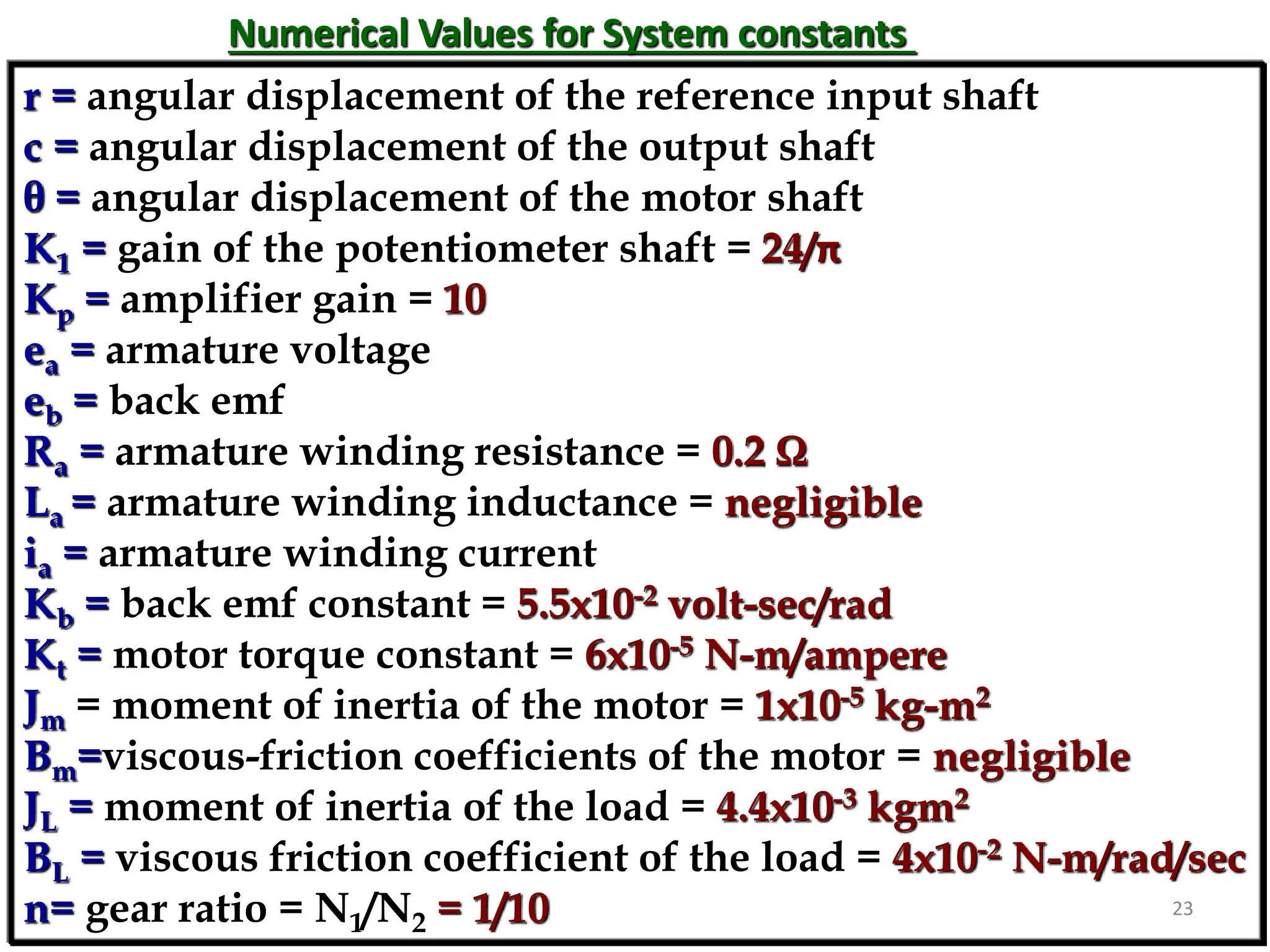

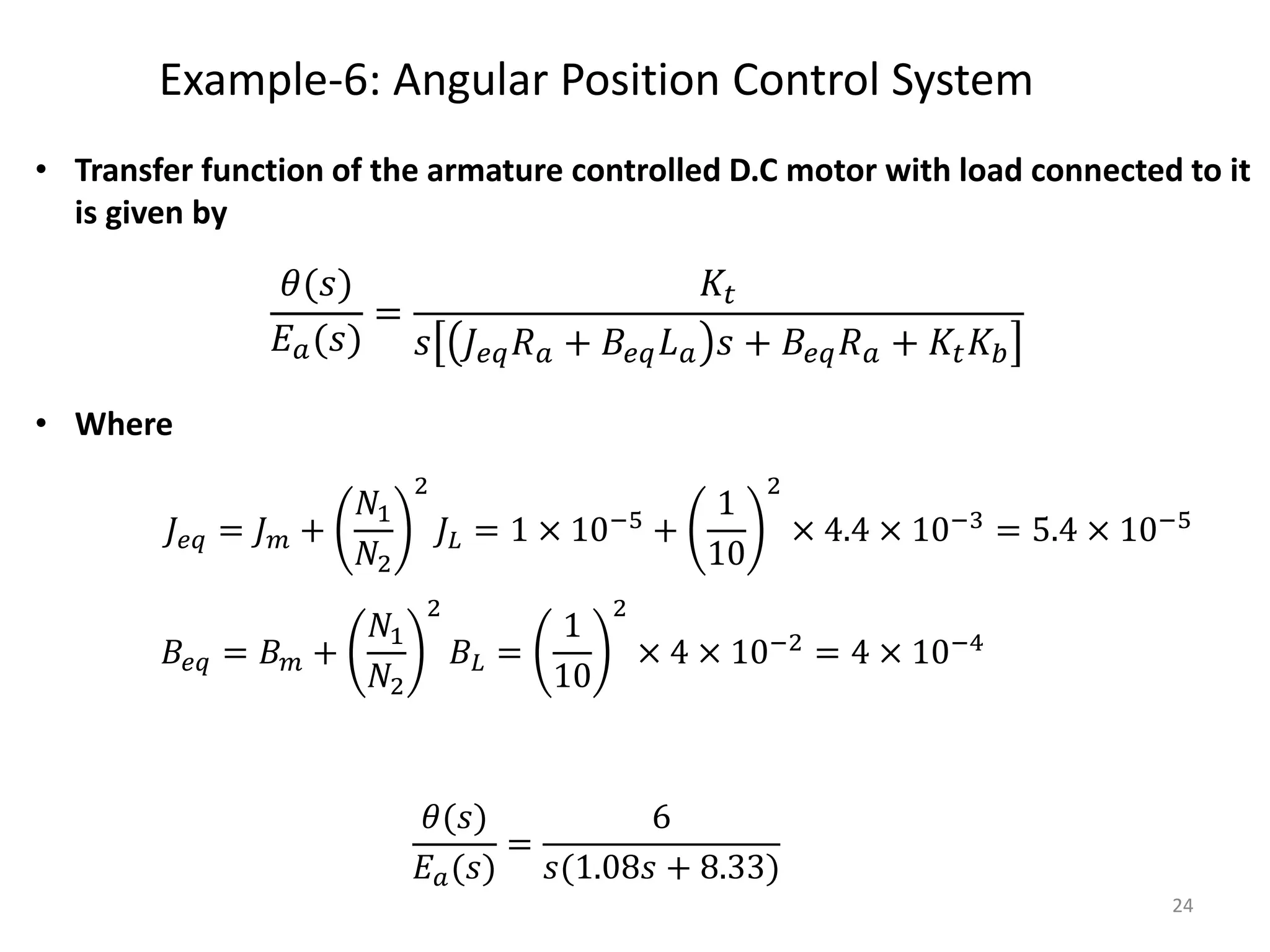

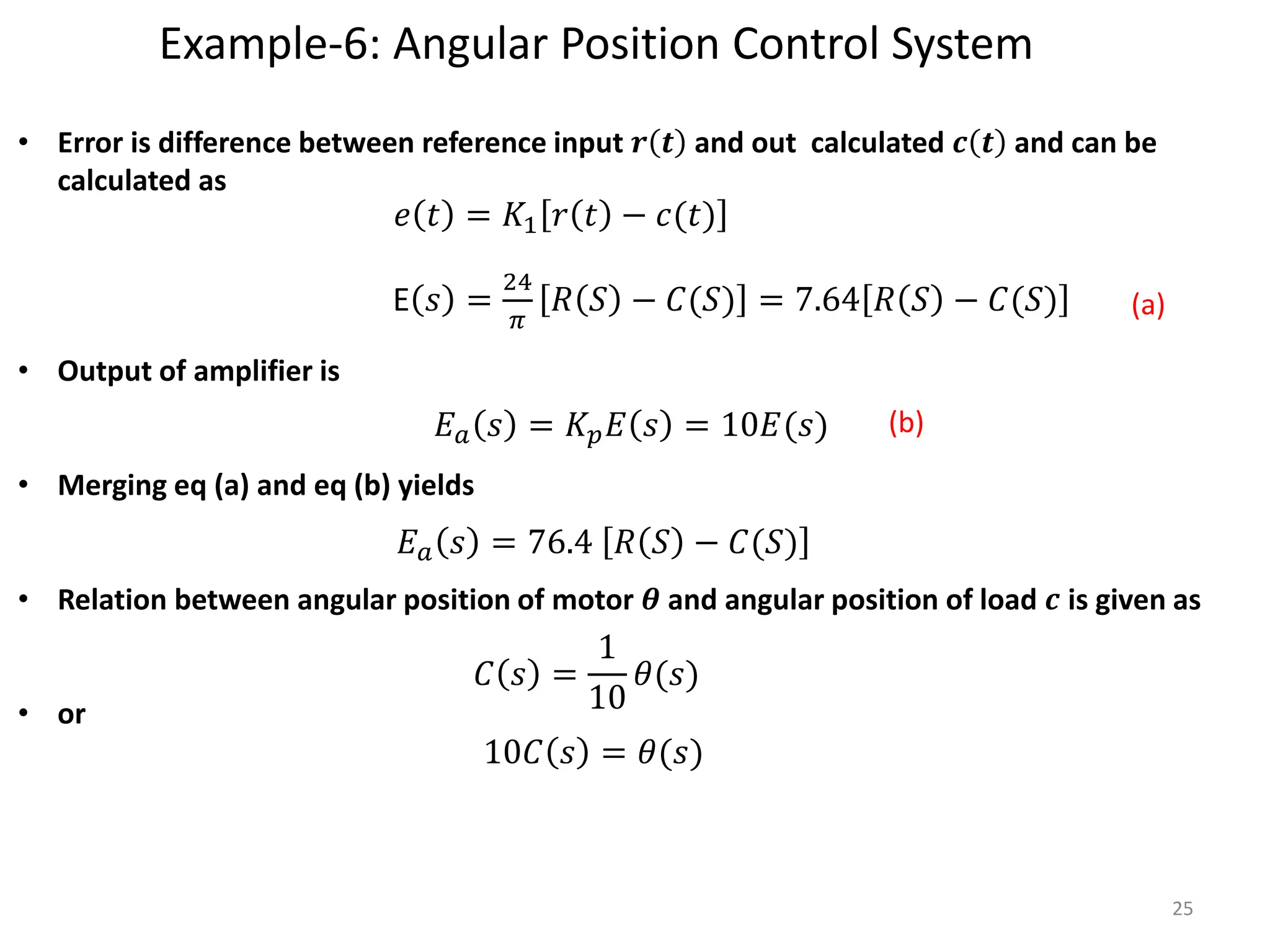

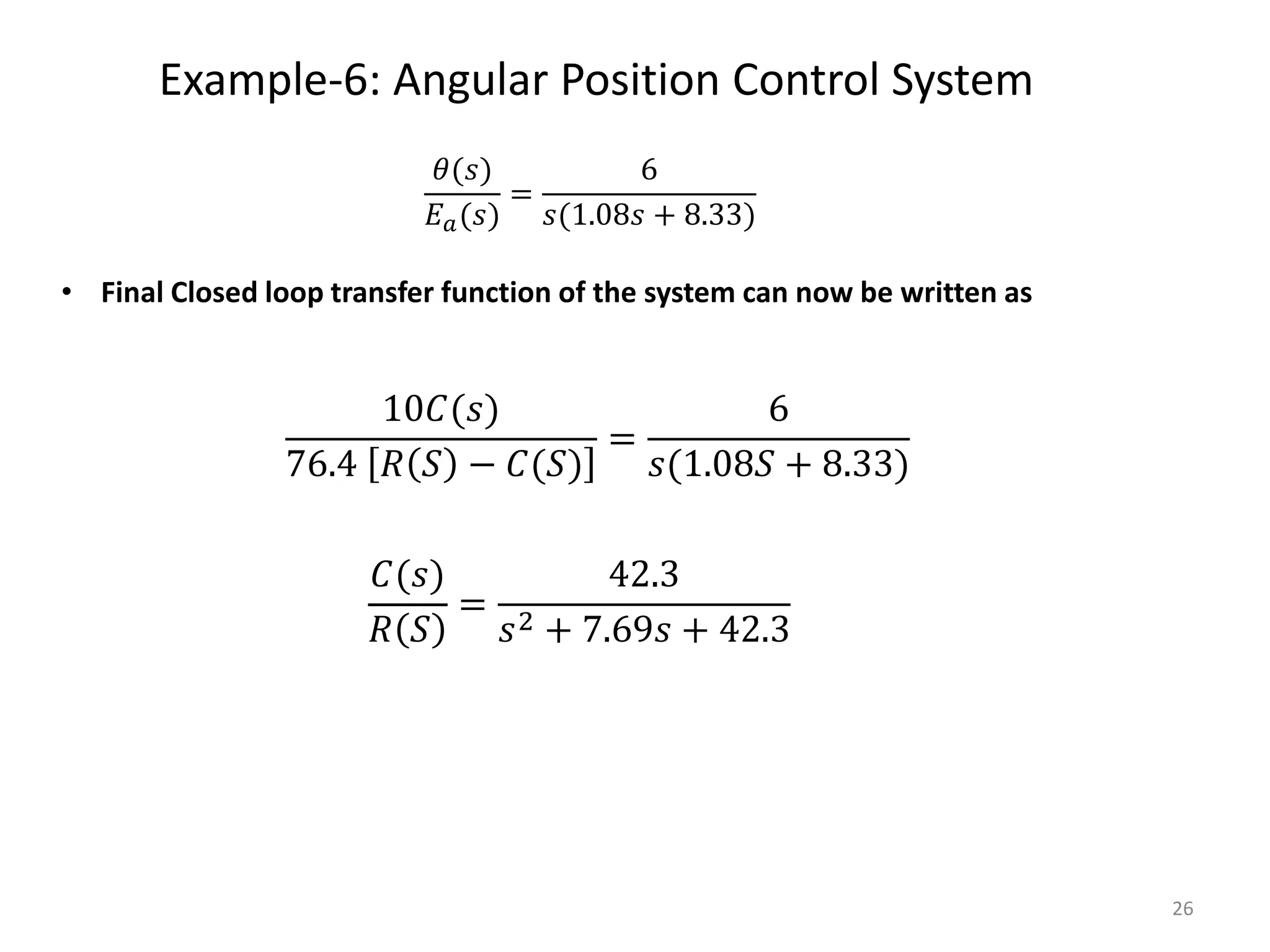

The document discusses mathematical modeling of electromechanical systems, focusing on components such as potentiometers, DC motors, and their operational characteristics. It explains the principles of speed control in DC drives, presents mathematical models, and transfer functions for both armature and field controlled DC motors. Finally, it provides examples involving system constants and gear ratios for motor speed and torque adjustments.