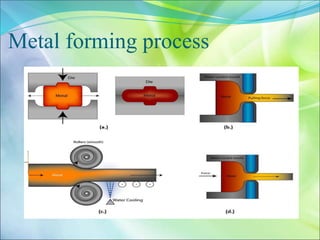

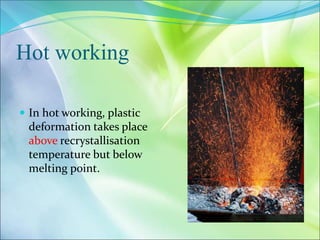

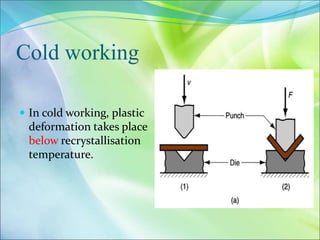

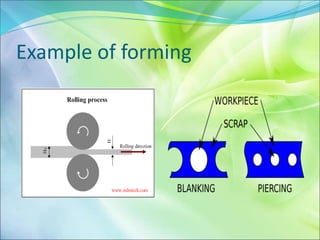

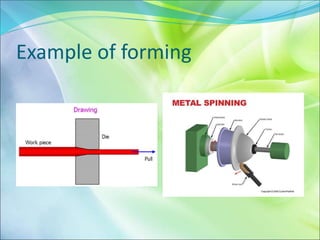

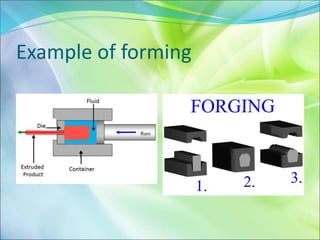

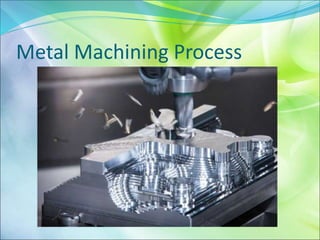

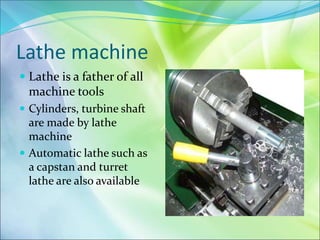

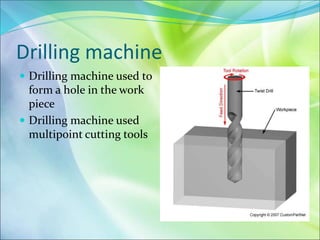

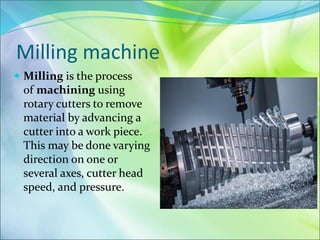

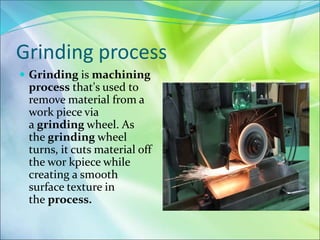

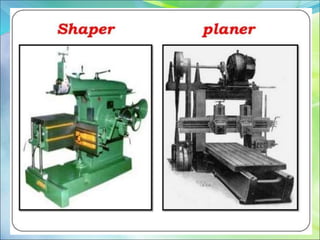

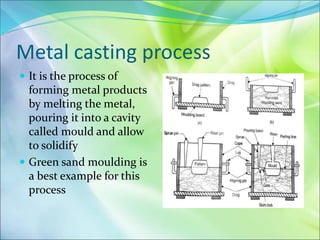

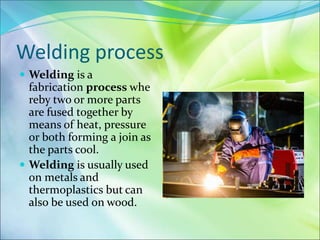

This document provides an overview of mechanical engineering and discusses several key sub-disciplines and processes including production engineering, metal forming, machining, casting, and welding. Production engineering involves converting raw materials into finished products through processes like forming, machining, joining, and casting. Metal forming changes a material's shape without changing its mass or composition, and can involve hot or cold working. Common metal forming examples include rolling, piercing, drawing, spinning, extrusion, and forging. Machining cuts material using machine tools like lathes, drilling machines, milling machines, and grinding machines. Metal casting involves melting metal and pouring it into a mold to solidify. Welding fuses materials together using heat, pressure, or