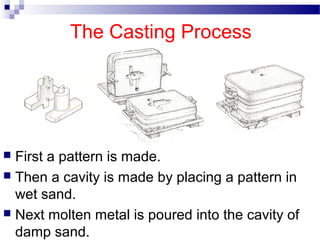

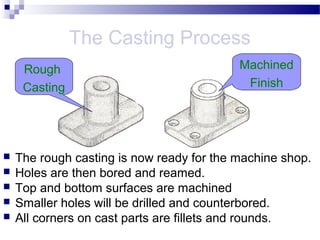

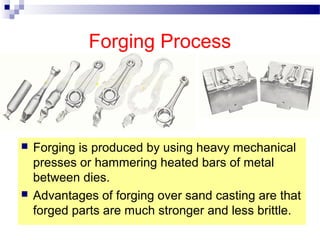

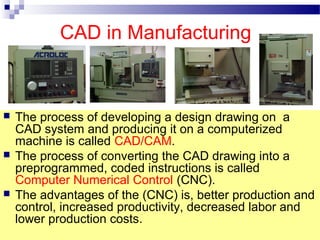

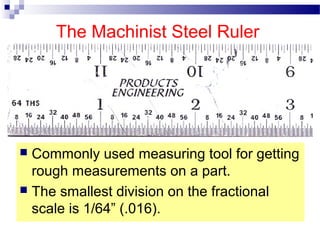

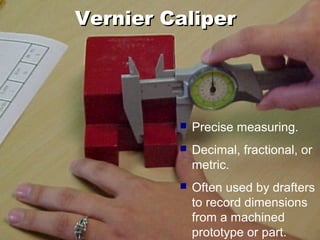

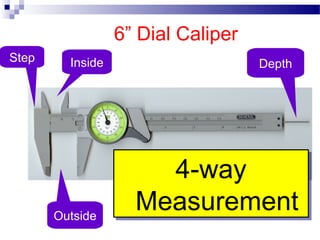

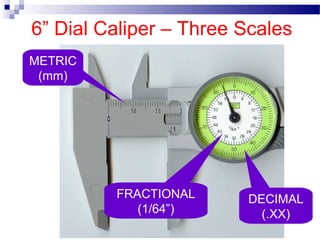

The document discusses basic machine processes and manufacturing. It defines manufacturing as converting raw materials into products using processes like casting, forging, and welding. It describes the three phases of manufacturing as product design, material selection, and choosing production methods. The main stages of machined part production are rough forming, finishing, and assembling. Common measuring tools for machinists are steel rulers, vernier calipers, and dial calipers.