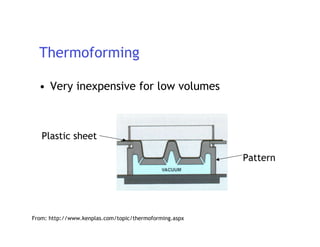

The document discusses various manufacturing processes used to convert raw materials into products. It begins by contrasting prototypes, which are one-offs, from products which need to be manufactured at scale. It emphasizes designing for manufacturability and considering factors like cost, quality and repeatability when scaling production. The rest of the document then provides detailed descriptions and examples of many common manufacturing processes, grouping them into categories like subtractive processes, additive processes, continuous processes and net shape forming. Specific processes discussed include casting, machining, welding, injection molding, thermoforming and more.