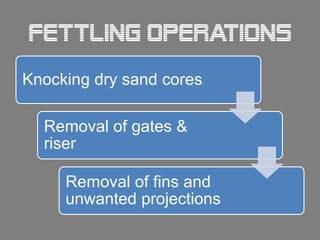

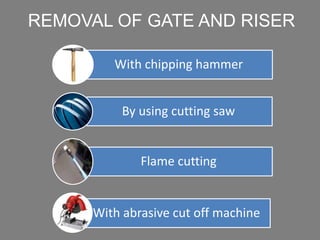

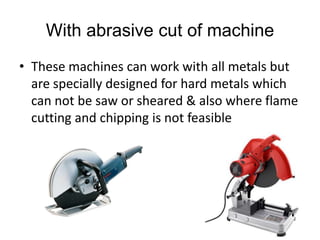

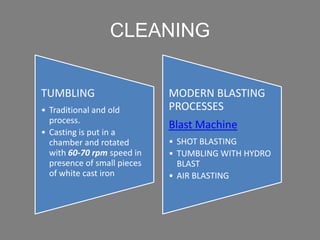

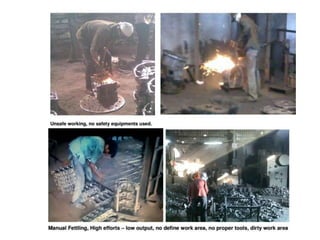

Fettling is the process of preparing castings for use by removing unwanted material like gates, risers, fins, and imperfections. It involves several steps and techniques. First, dry sand cores are knocked out and gates and risers are removed through chipping, cutting, sawing, or abrasive machining depending on the material. Then fins and other projections on the casting surface are chipped off. Finally, the casting is cleaned through tumbling, shot blasting, or other modern blasting processes to produce a smooth, finished part meeting specifications. Fettling transforms crude castings into functional, high quality components through various removal and cleaning operations.