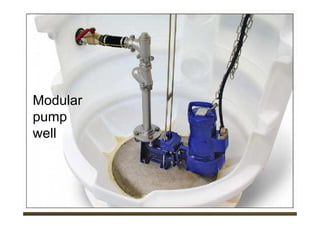

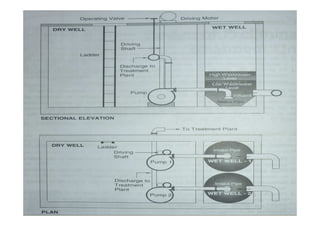

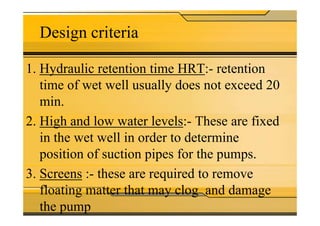

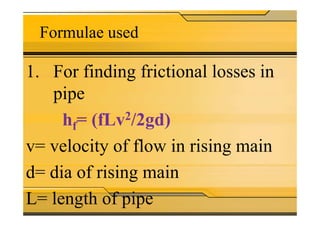

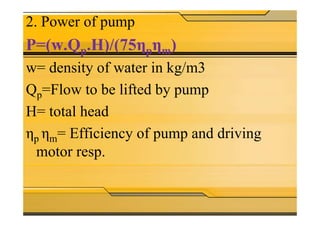

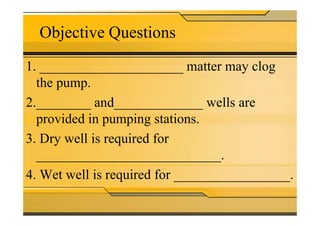

The document discusses sewage pumping stations. Sewage pumping stations are needed when sewage must be raised to flow by gravity, such as when basements are too low to discharge into main sewers or sewage must be conveyed over ridges. Problems with sewage pumping include fouling, solids causing clogs, corrosion from waste, health risks from pathogens, and flow variations. Pumping stations have dry wells to house pumps and wet wells for incoming sewage. Design considerations include retention time, water levels, screens, standby pumps, space for future pumps, and formulas for head loss and pump power.