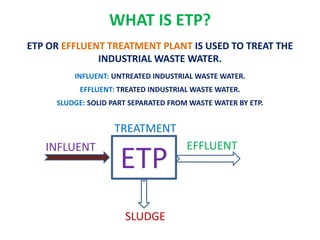

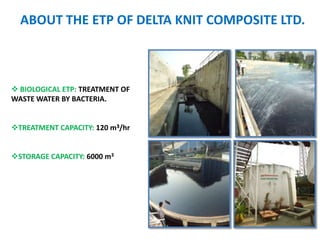

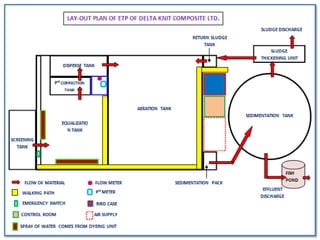

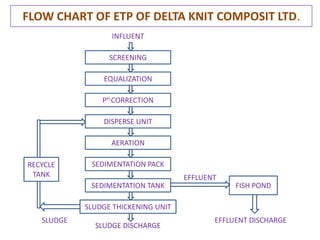

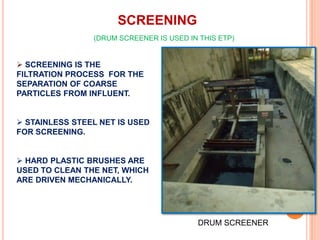

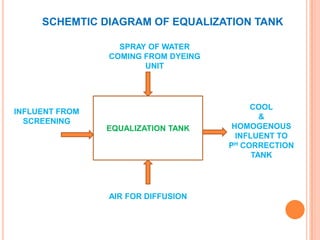

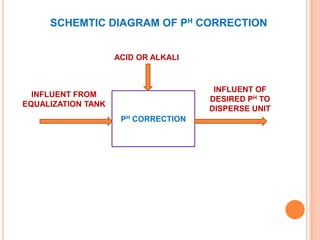

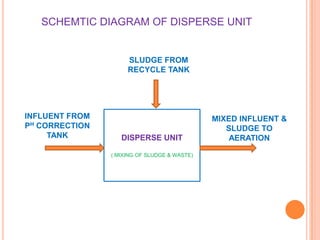

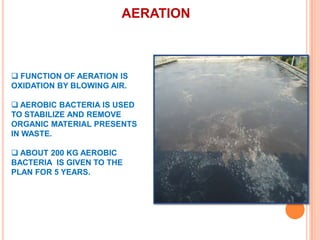

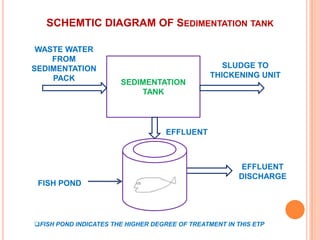

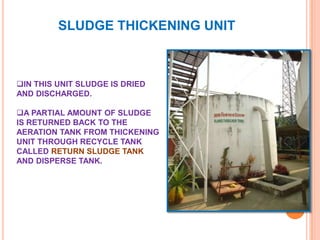

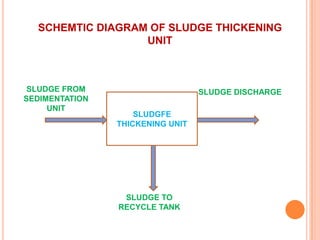

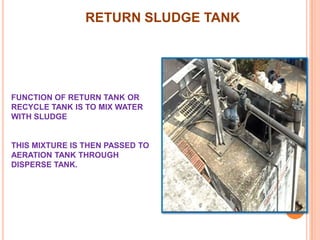

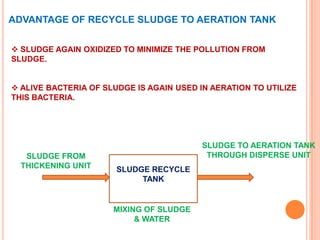

This document describes the effluent treatment plant (ETP) of Delta Knit Composite Ltd. The ETP uses a biological treatment process to treat 120 m3/hr of industrial wastewater. The treatment process includes screening, equalization, pH correction, aeration, sedimentation, sludge thickening, and recycling of sludge. The ETP is able to reduce pollutants in the wastewater and produce treated effluent that can be safely discharged and dried sludge.