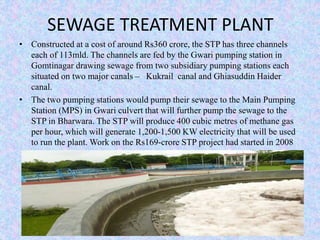

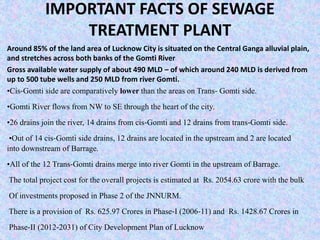

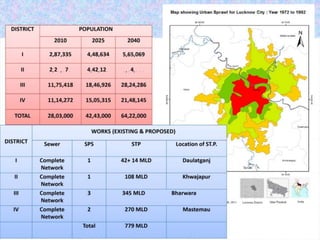

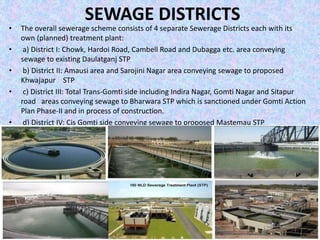

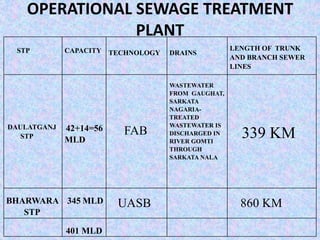

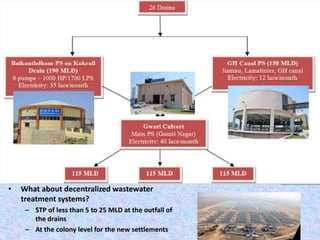

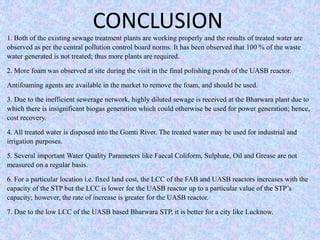

The document discusses sewage treatment in Lucknow, India. It describes two existing sewage treatment plants (STPs), Daulatganj STP and Bharwara STP, and notes that while they are working properly, not all wastewater is being treated. It also notes issues like insufficient biogas generation at Bharwara STP due to diluted sewage, and a need for tertiary treatment and water quality monitoring. Overall it evaluates the sewage infrastructure and treatment processes in Lucknow.