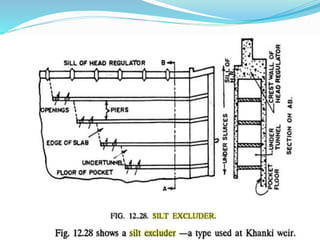

Silt excluders are structures used to reduce silt entering canals. They work by skimming off the upper layers of flowing water, which contain less silt, while diverting the lower, silt-rich layers through tunnels. Key aspects of silt excluder design include the tunnels covering some but not all of the undersluice bays and being flushed with the head regulator crest. The efficiency of silt excluders depends on factors like the amount of water diverted through the tunnels and the grade of sediment.