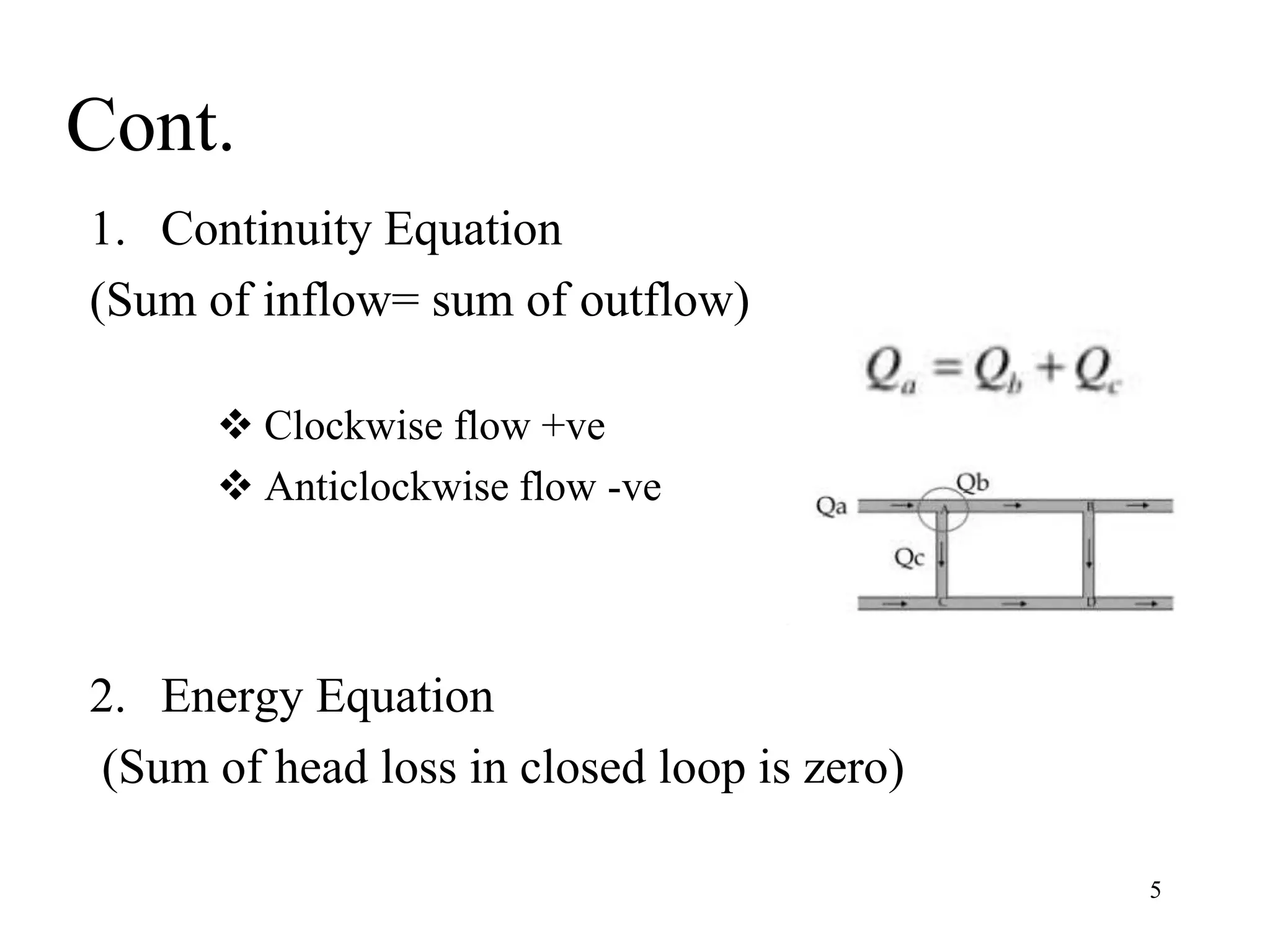

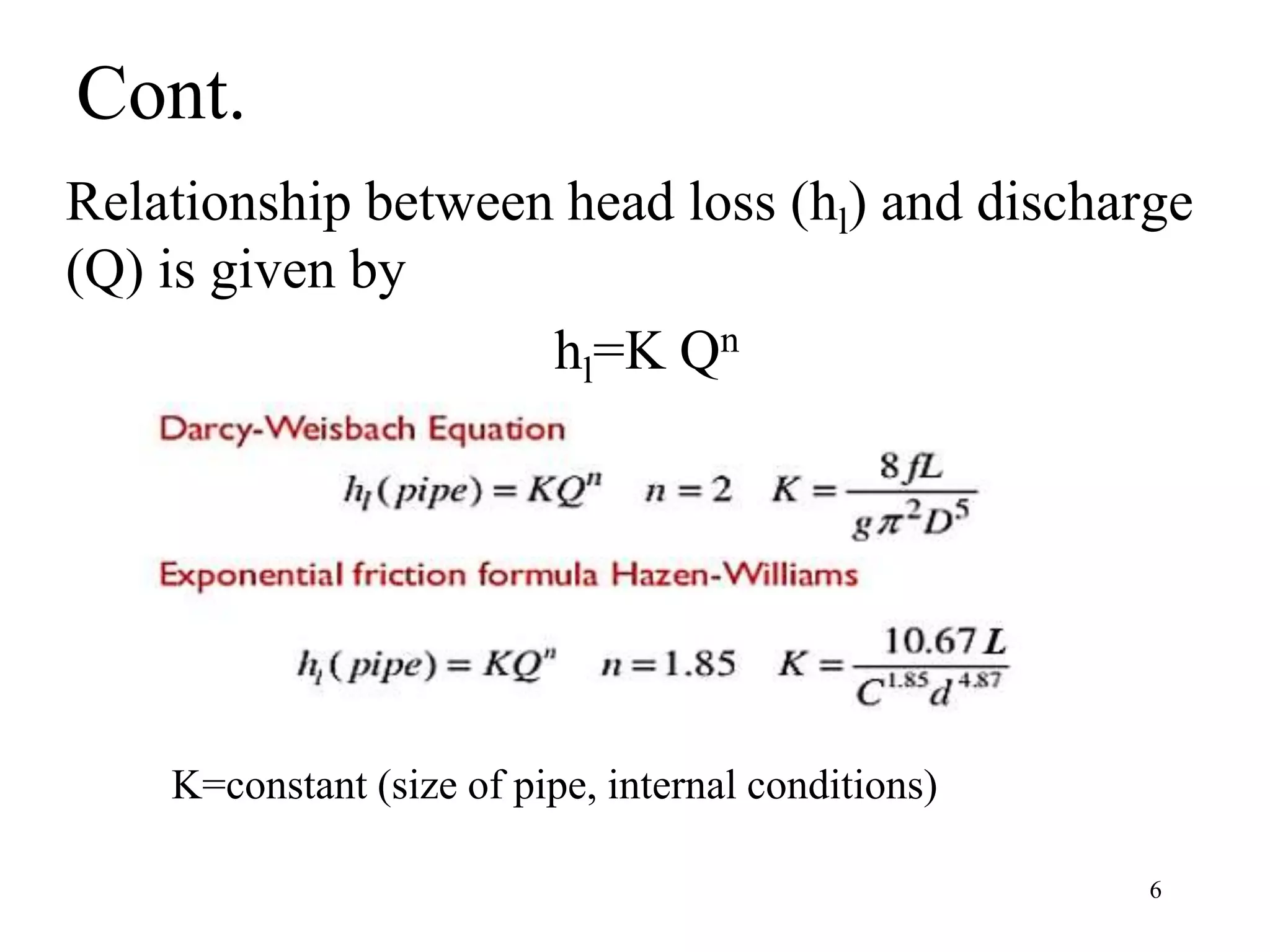

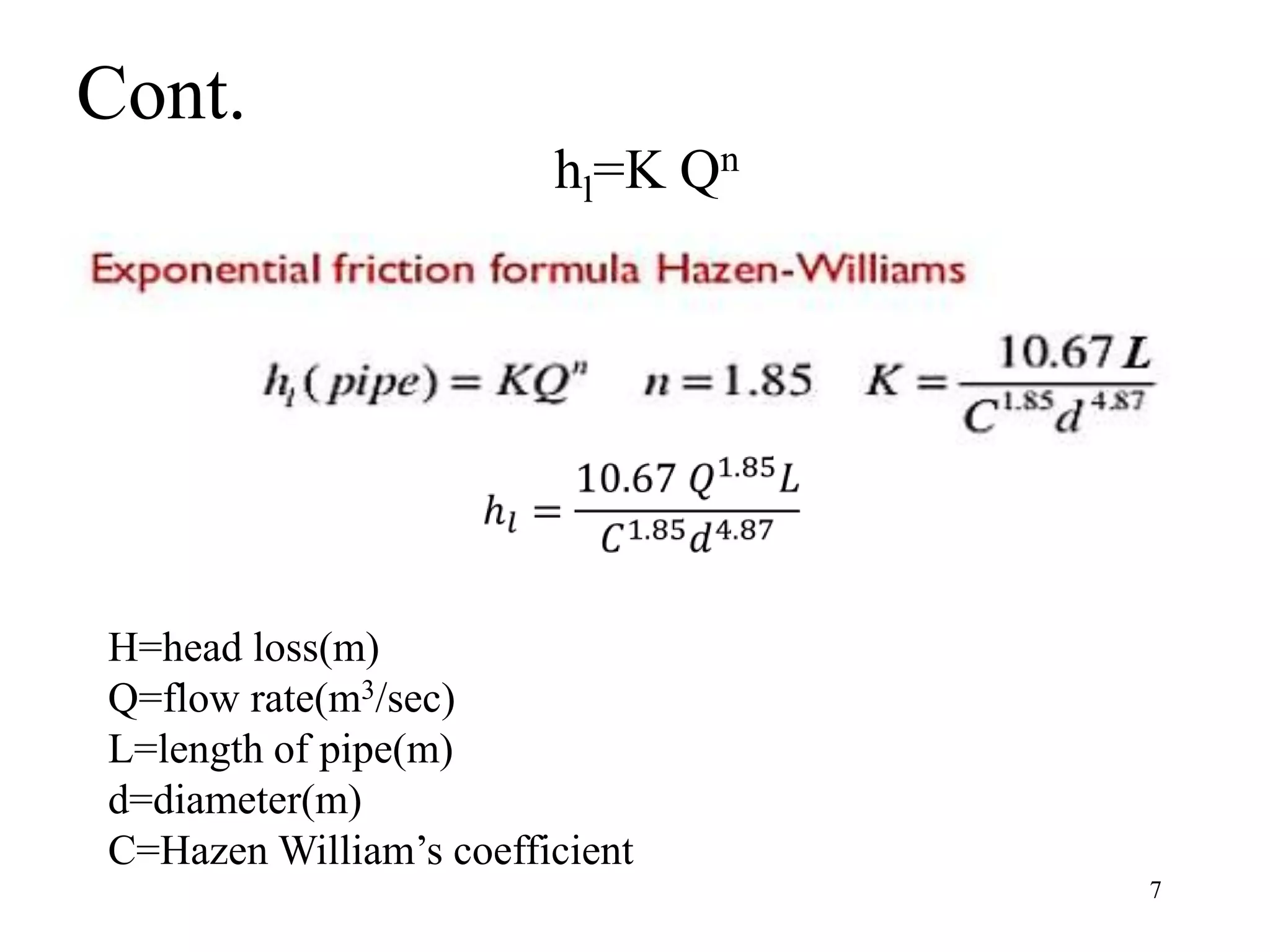

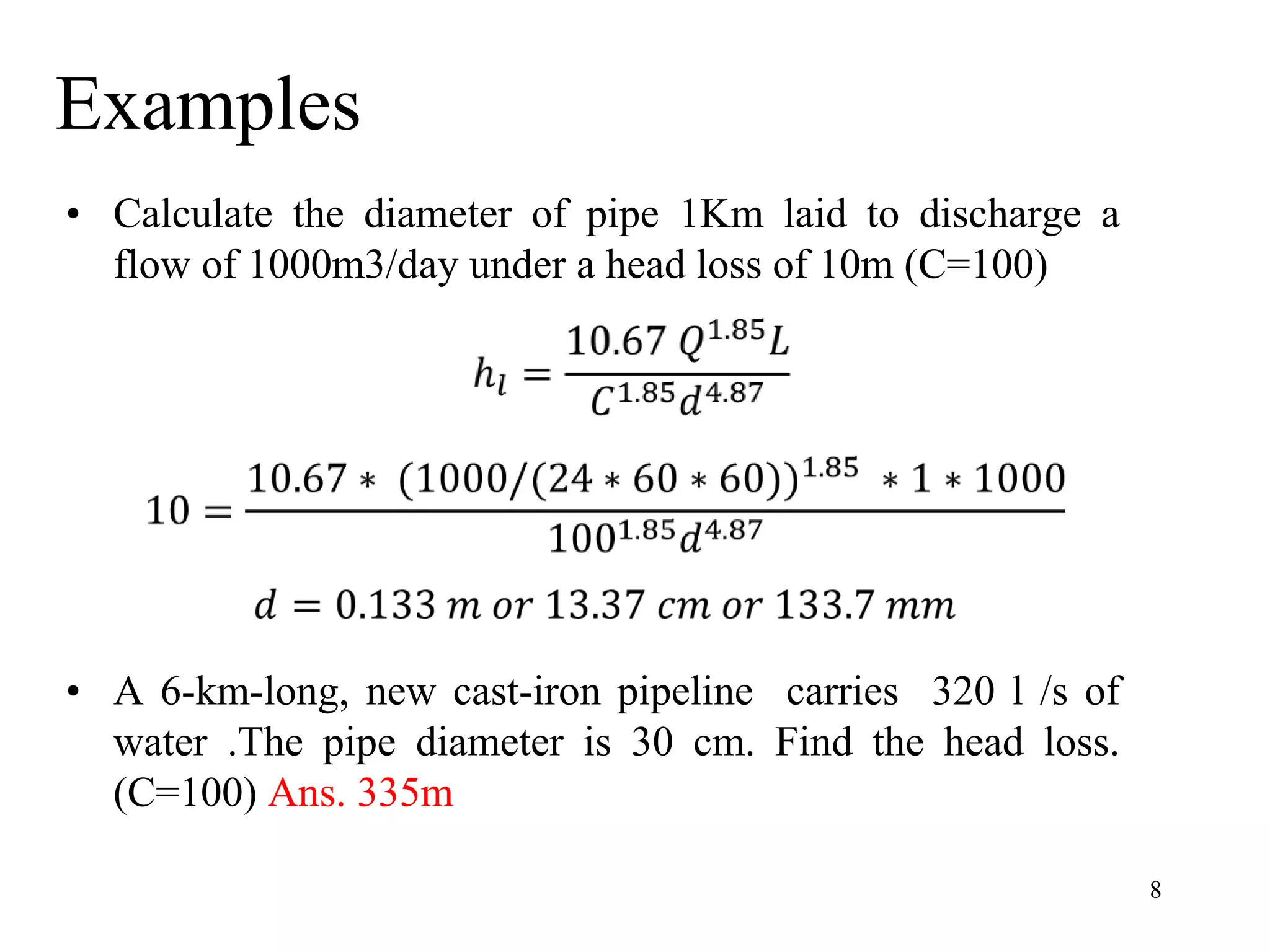

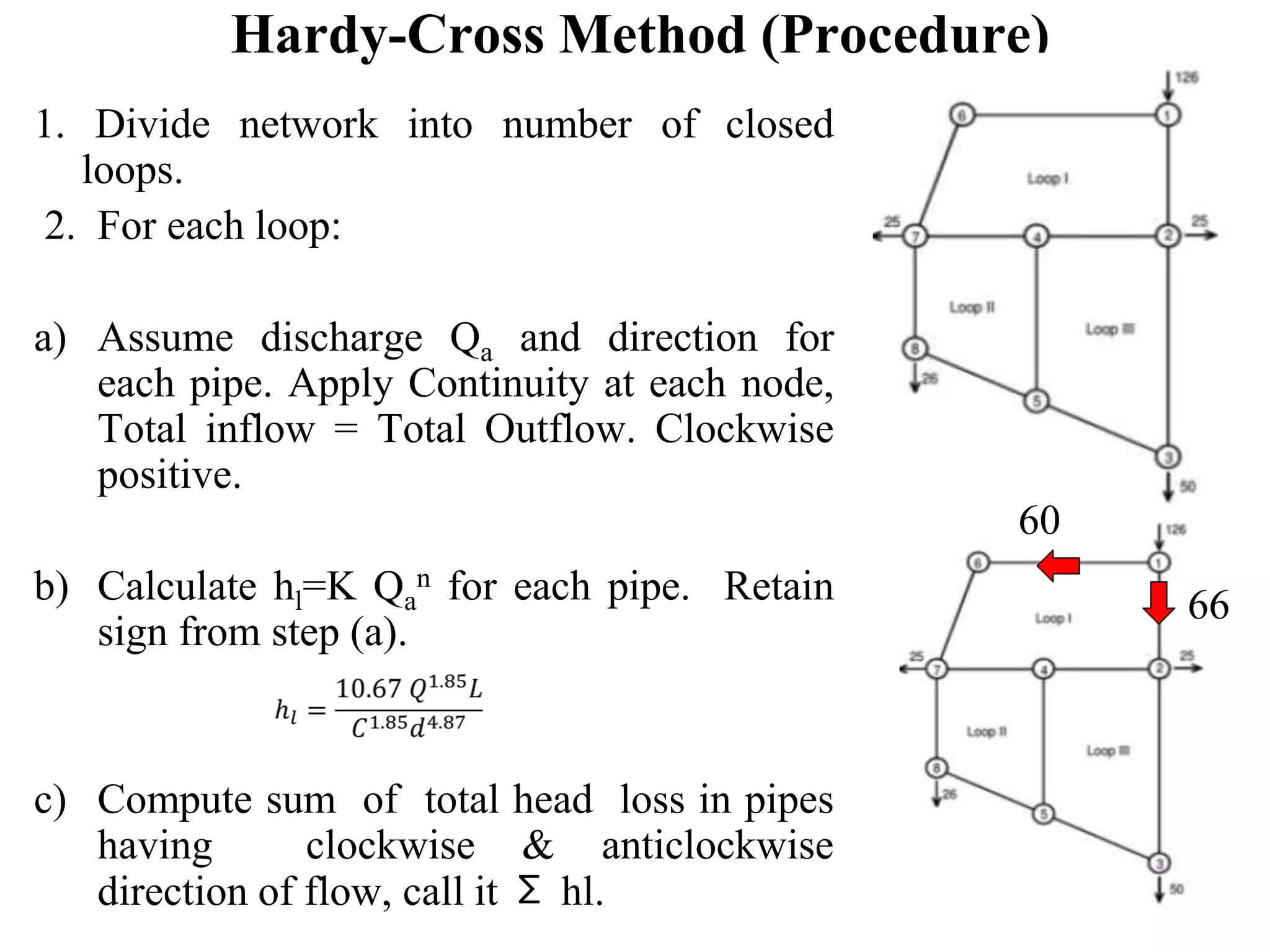

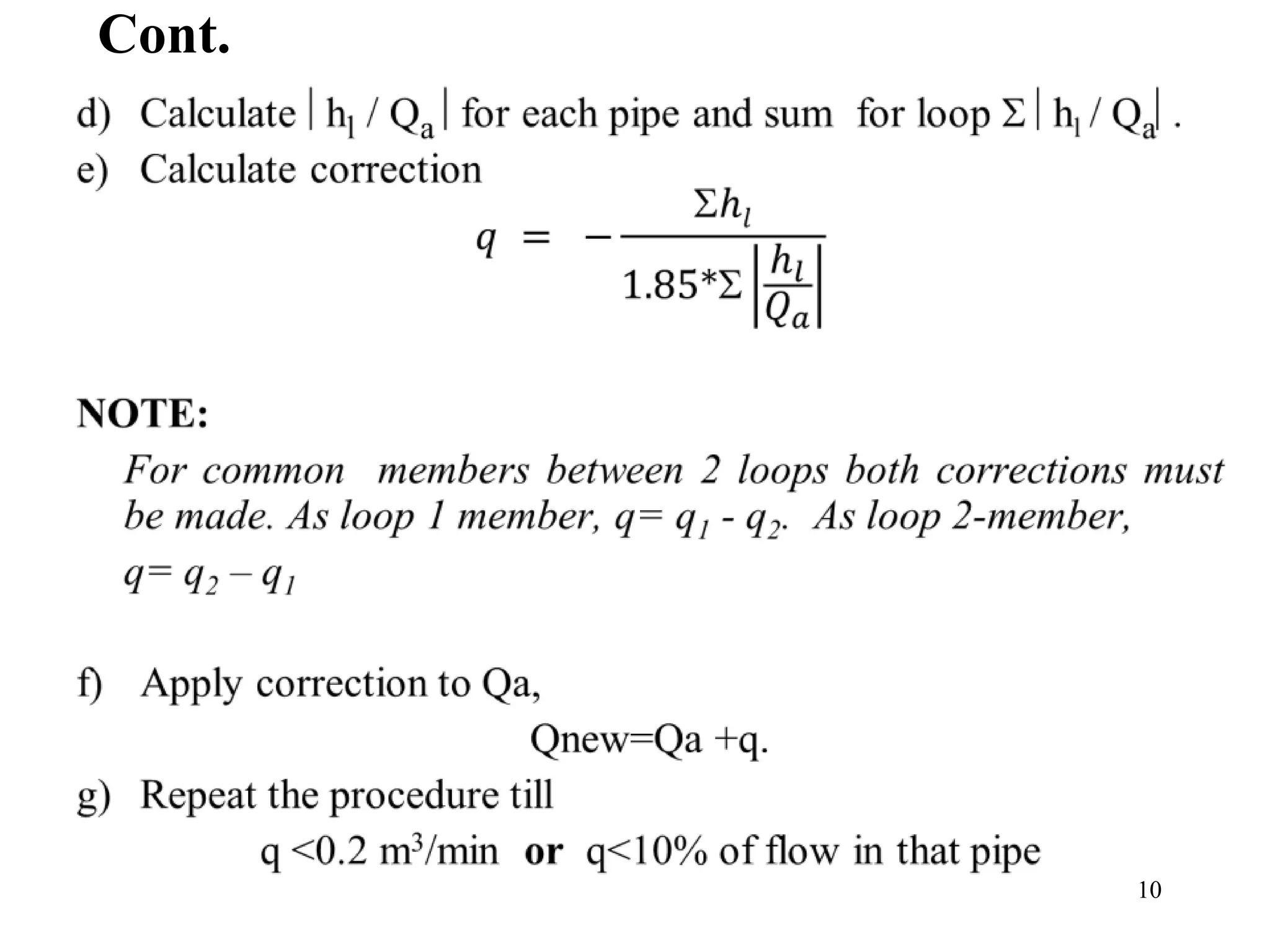

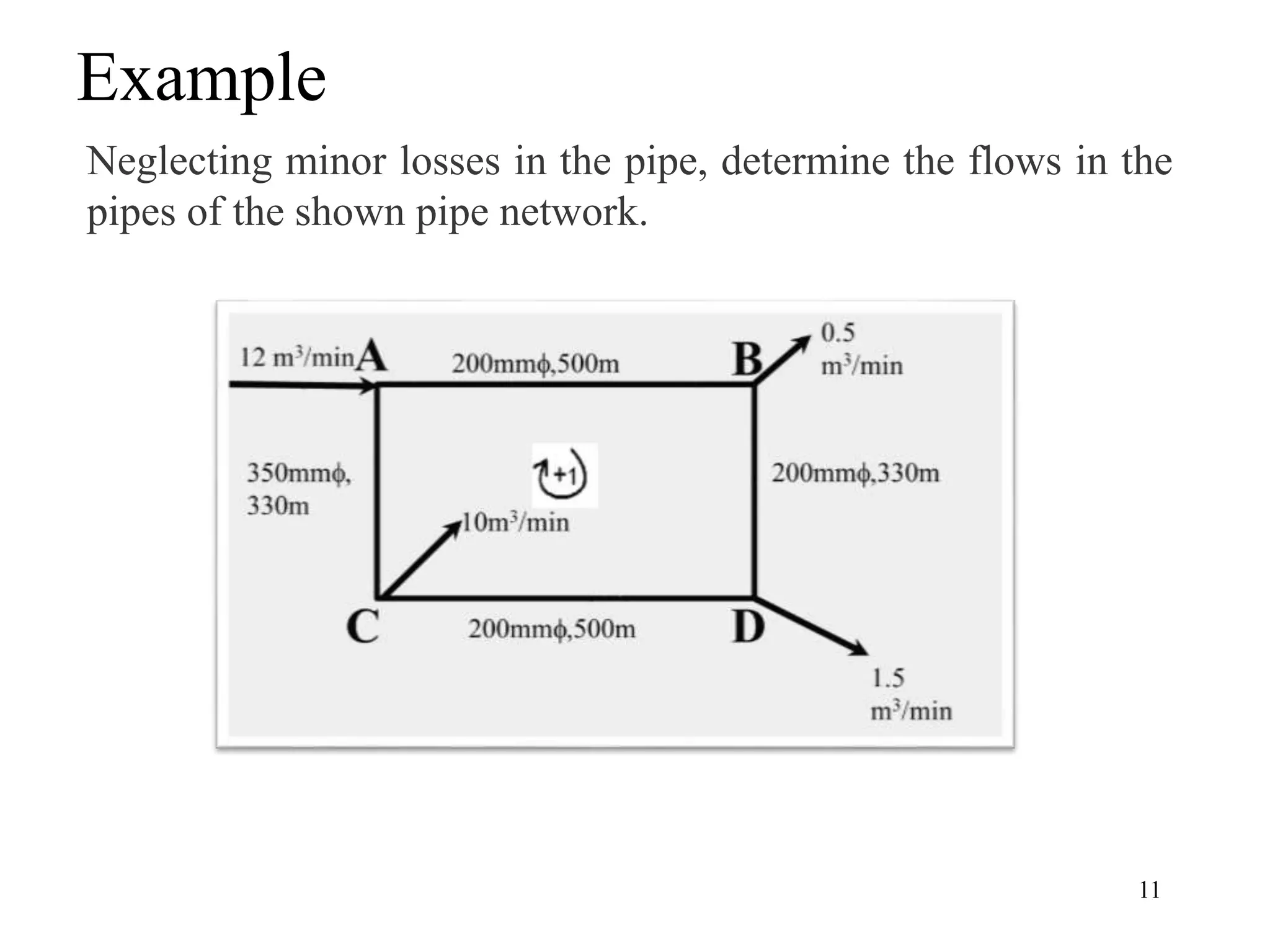

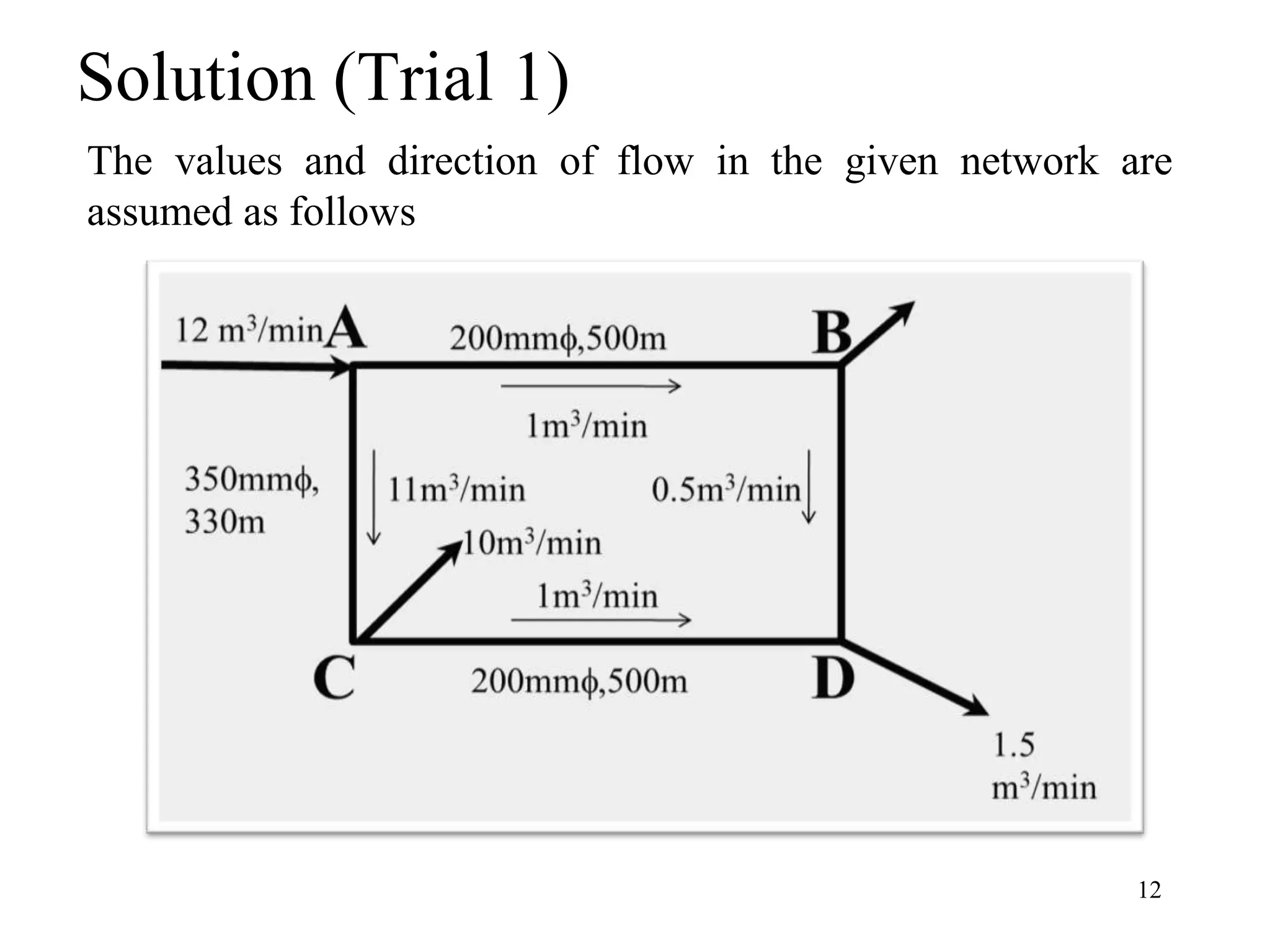

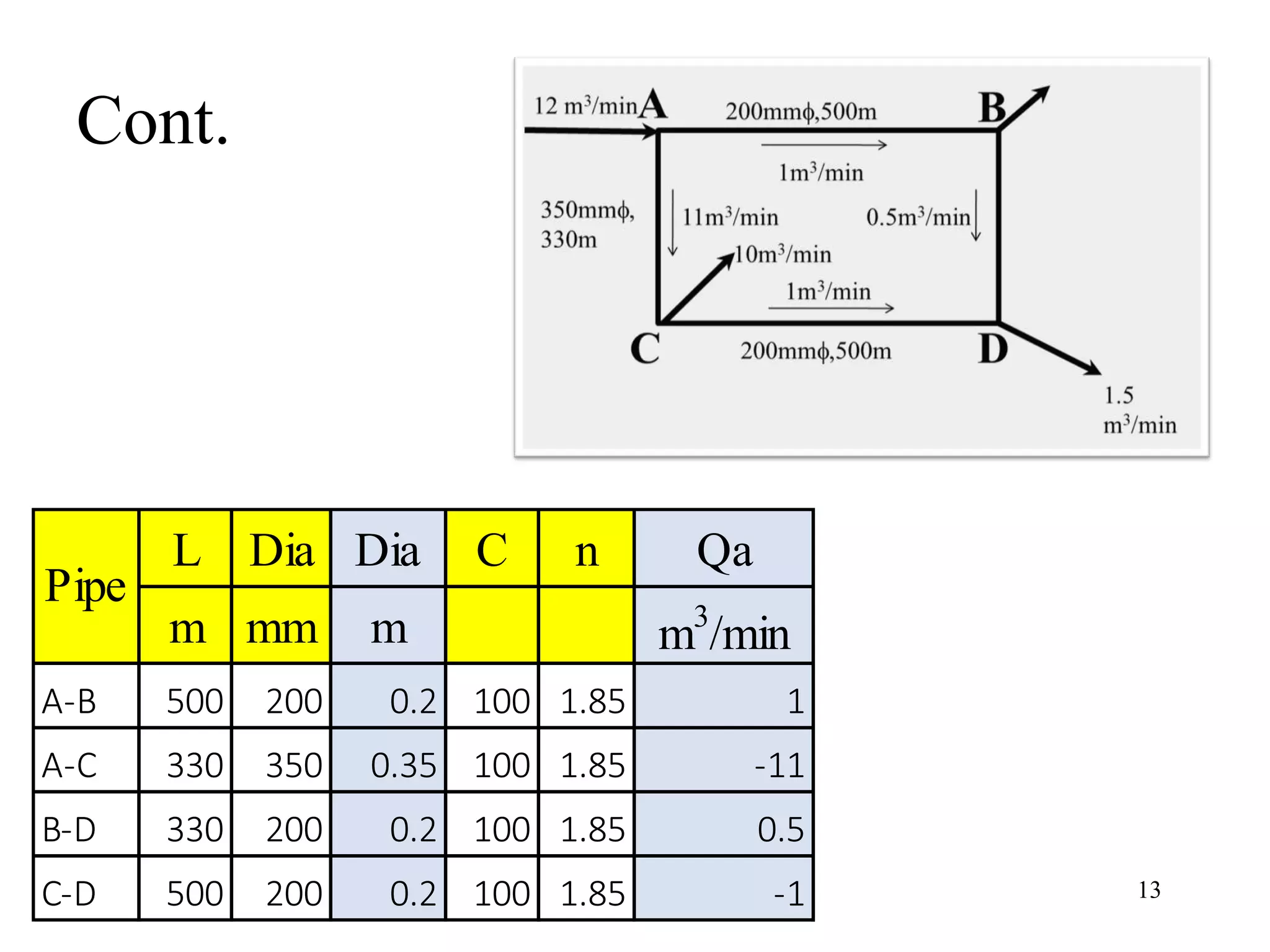

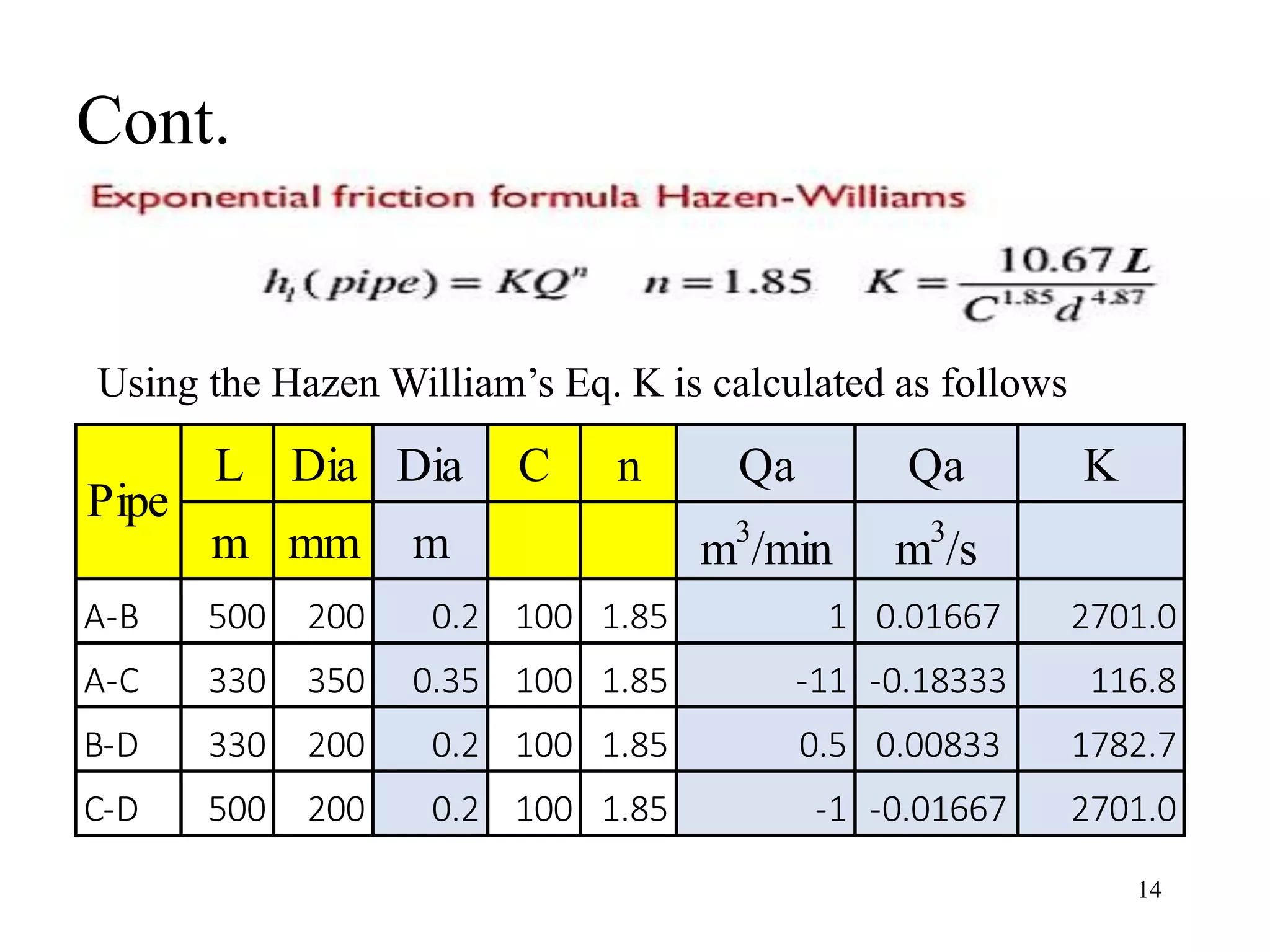

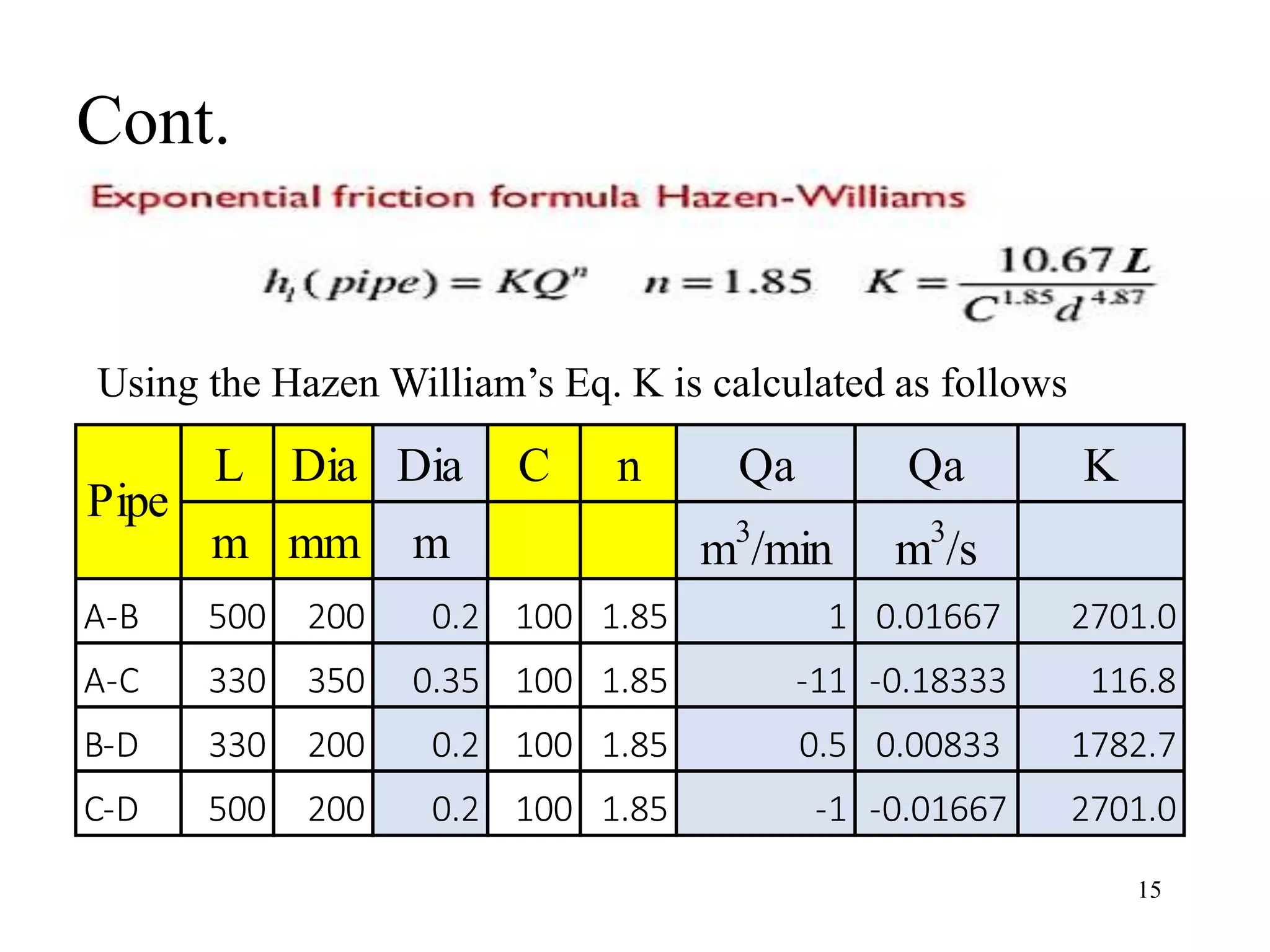

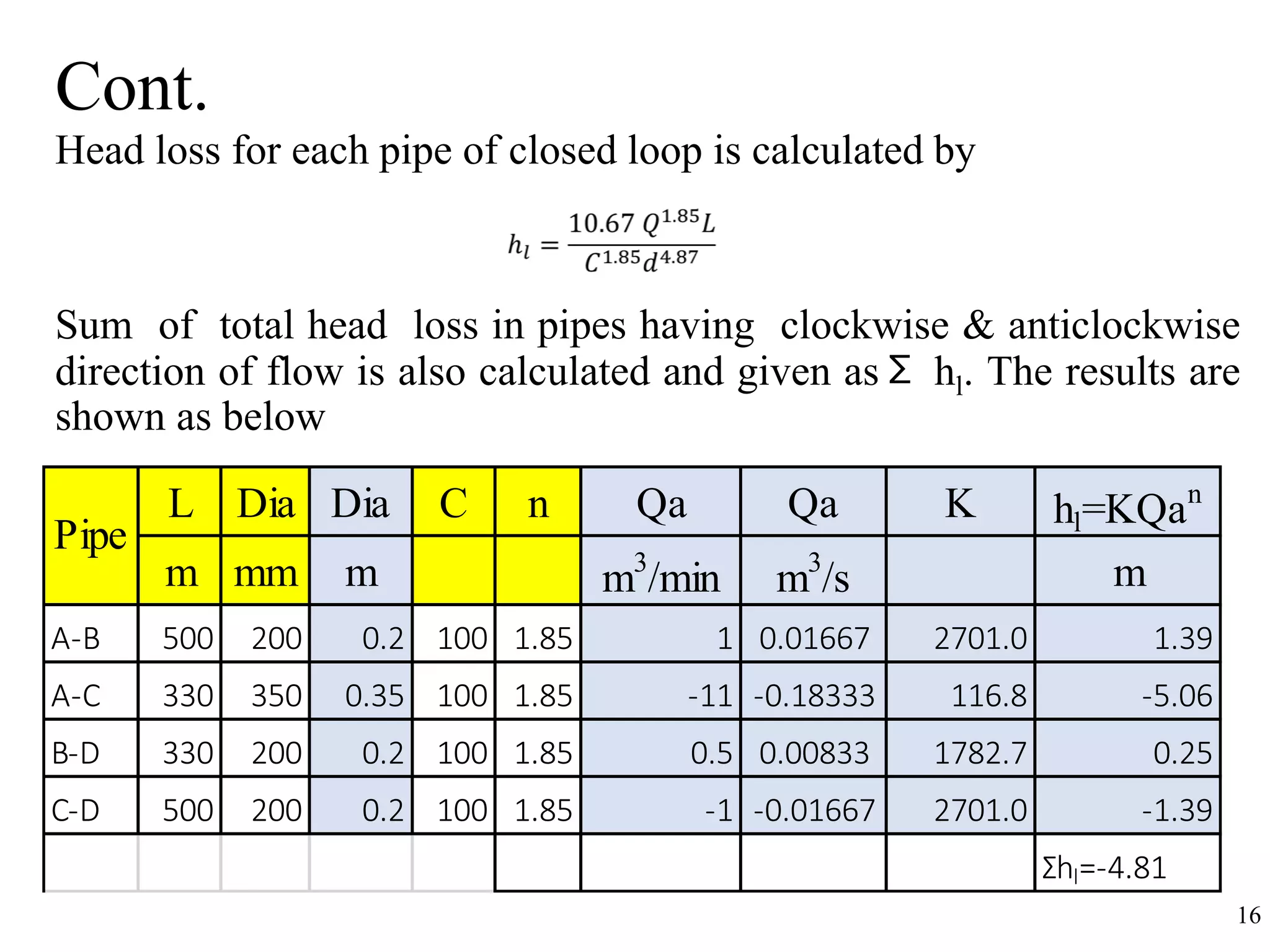

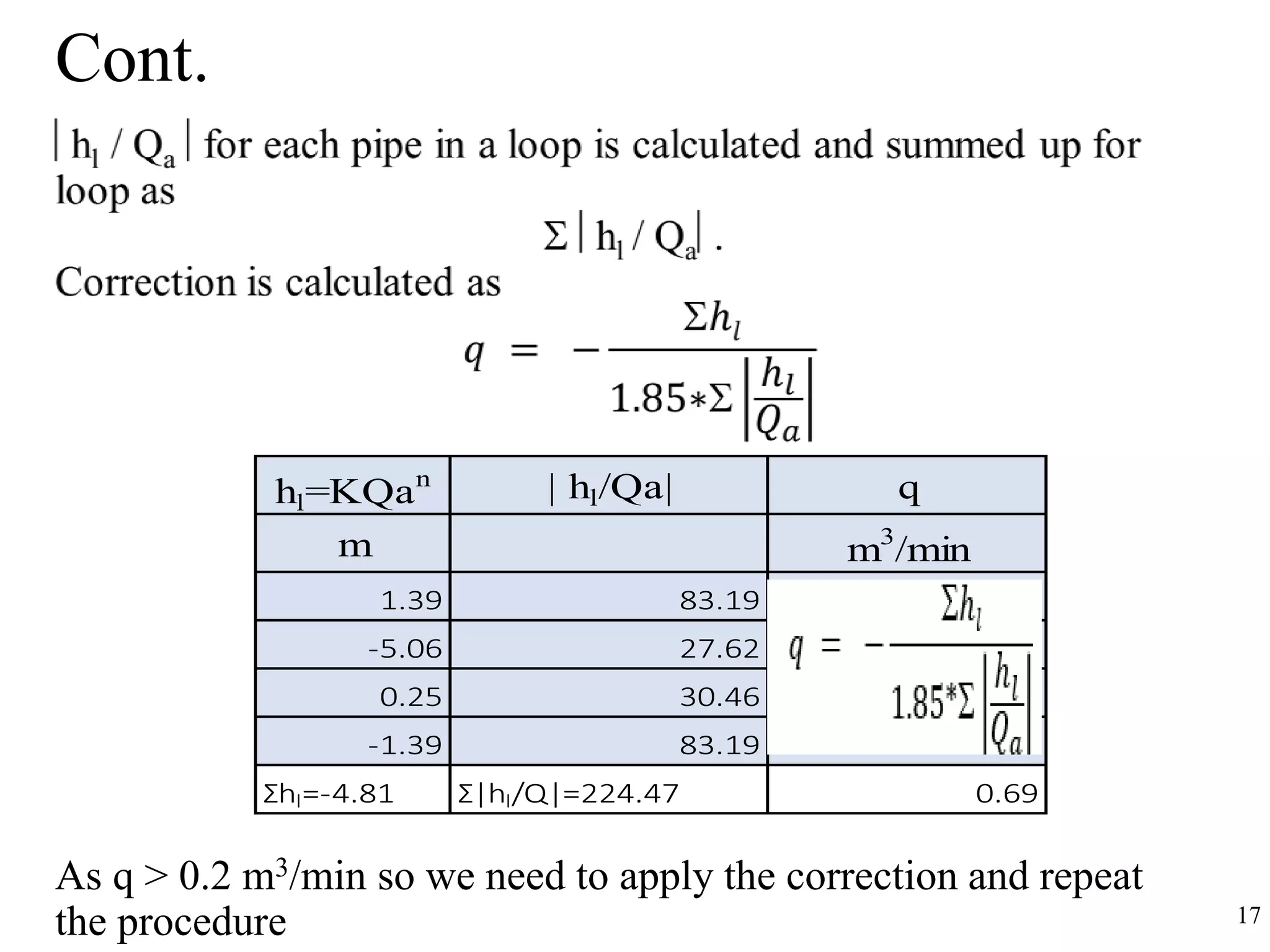

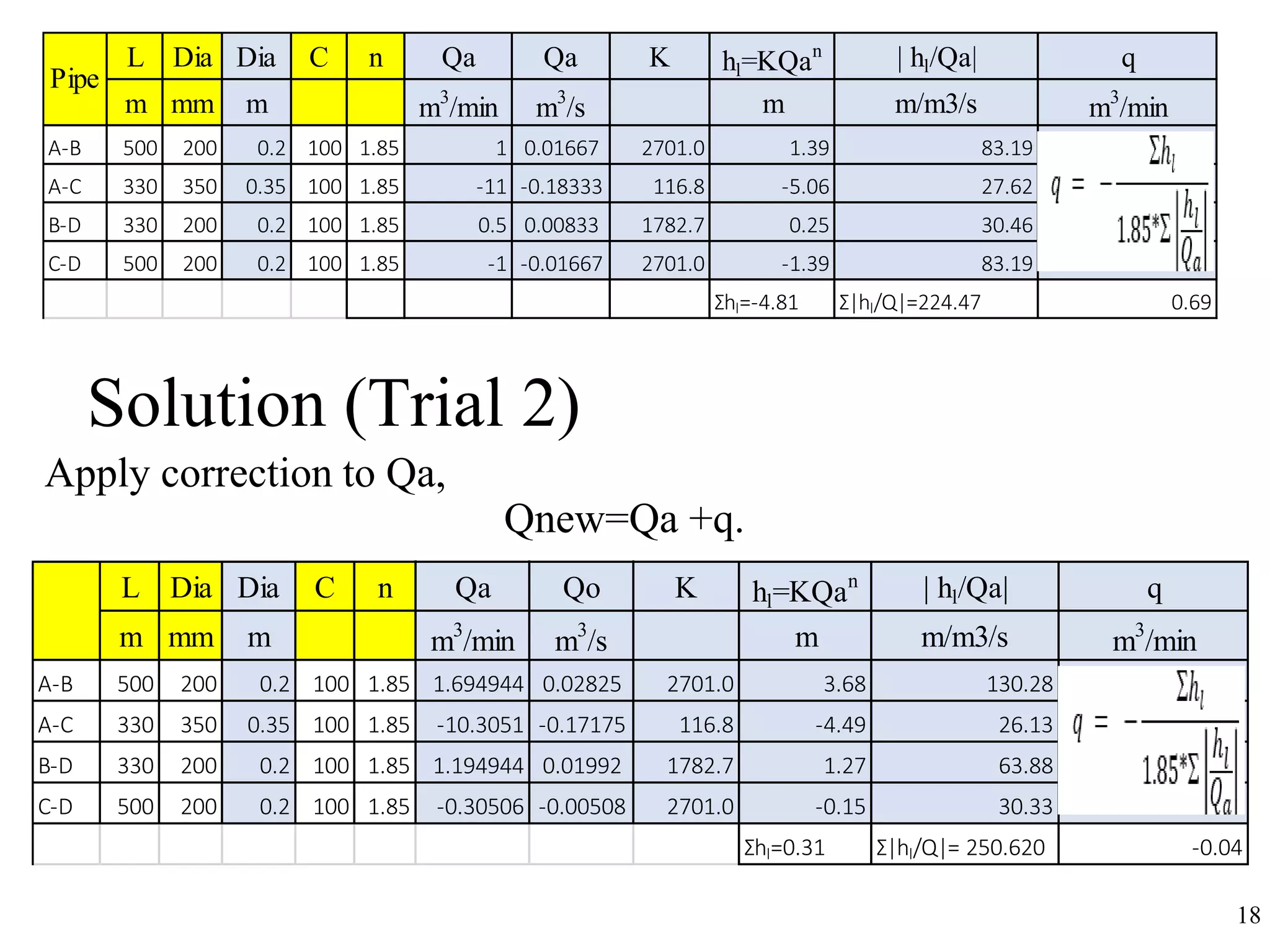

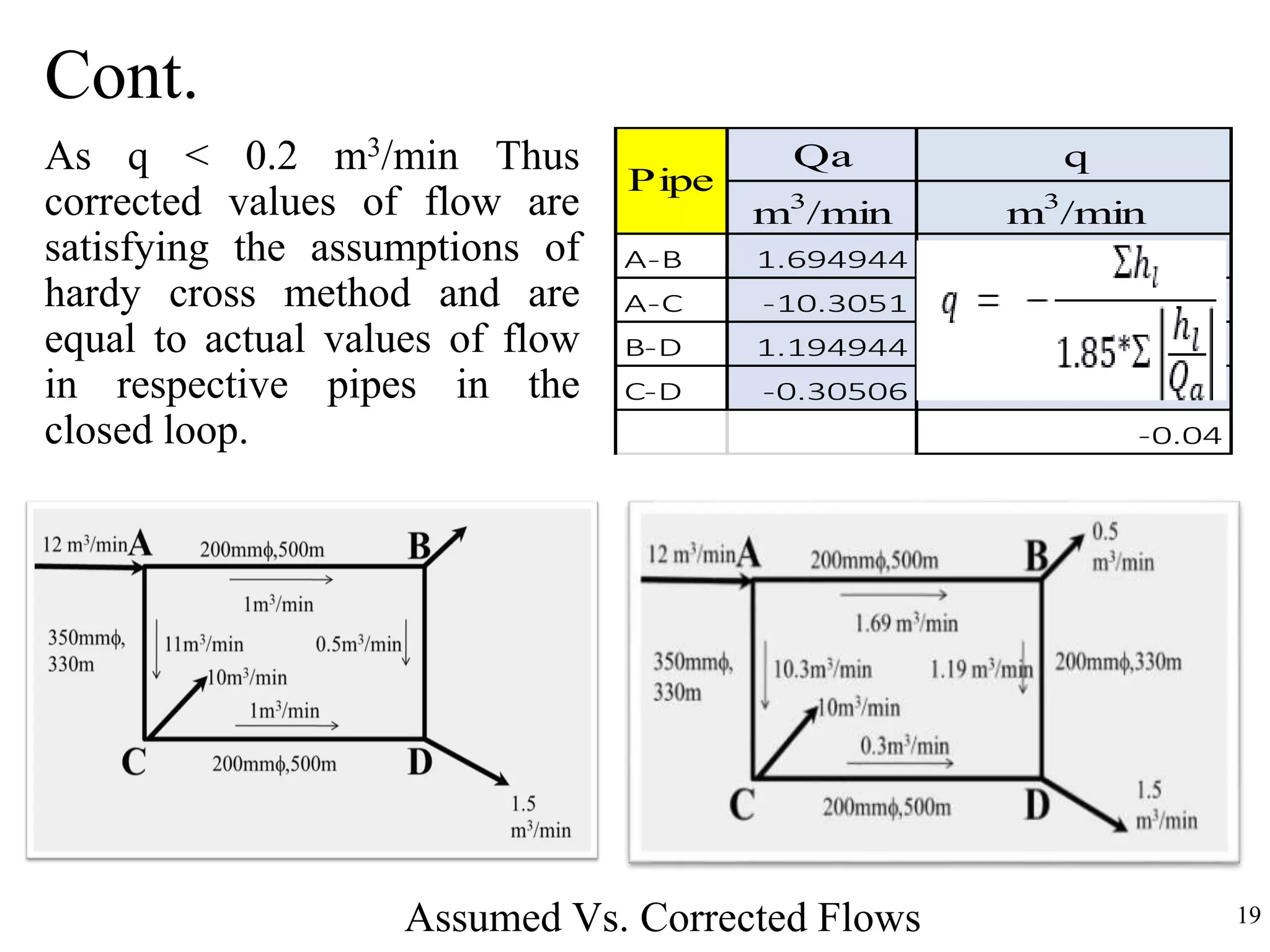

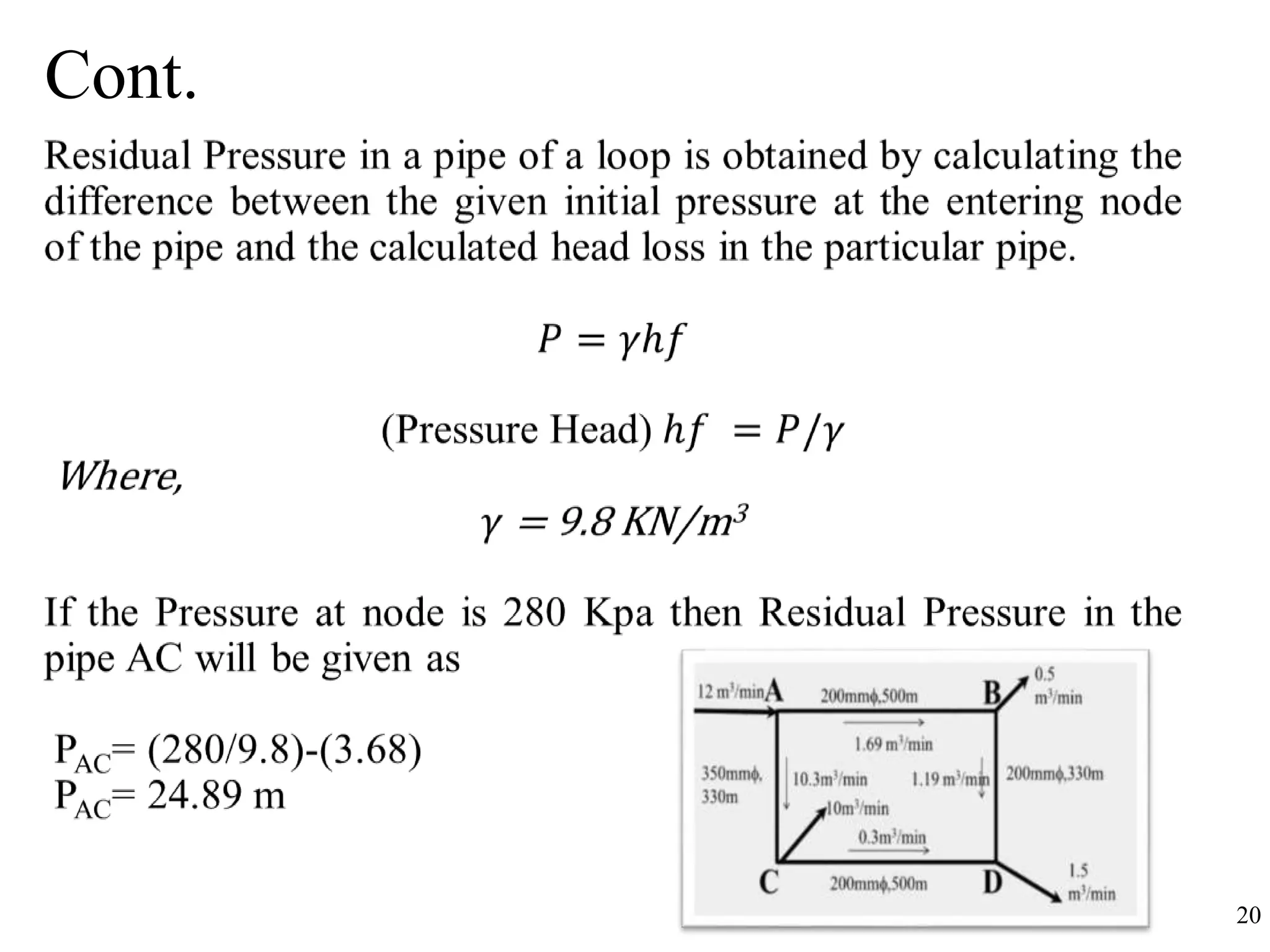

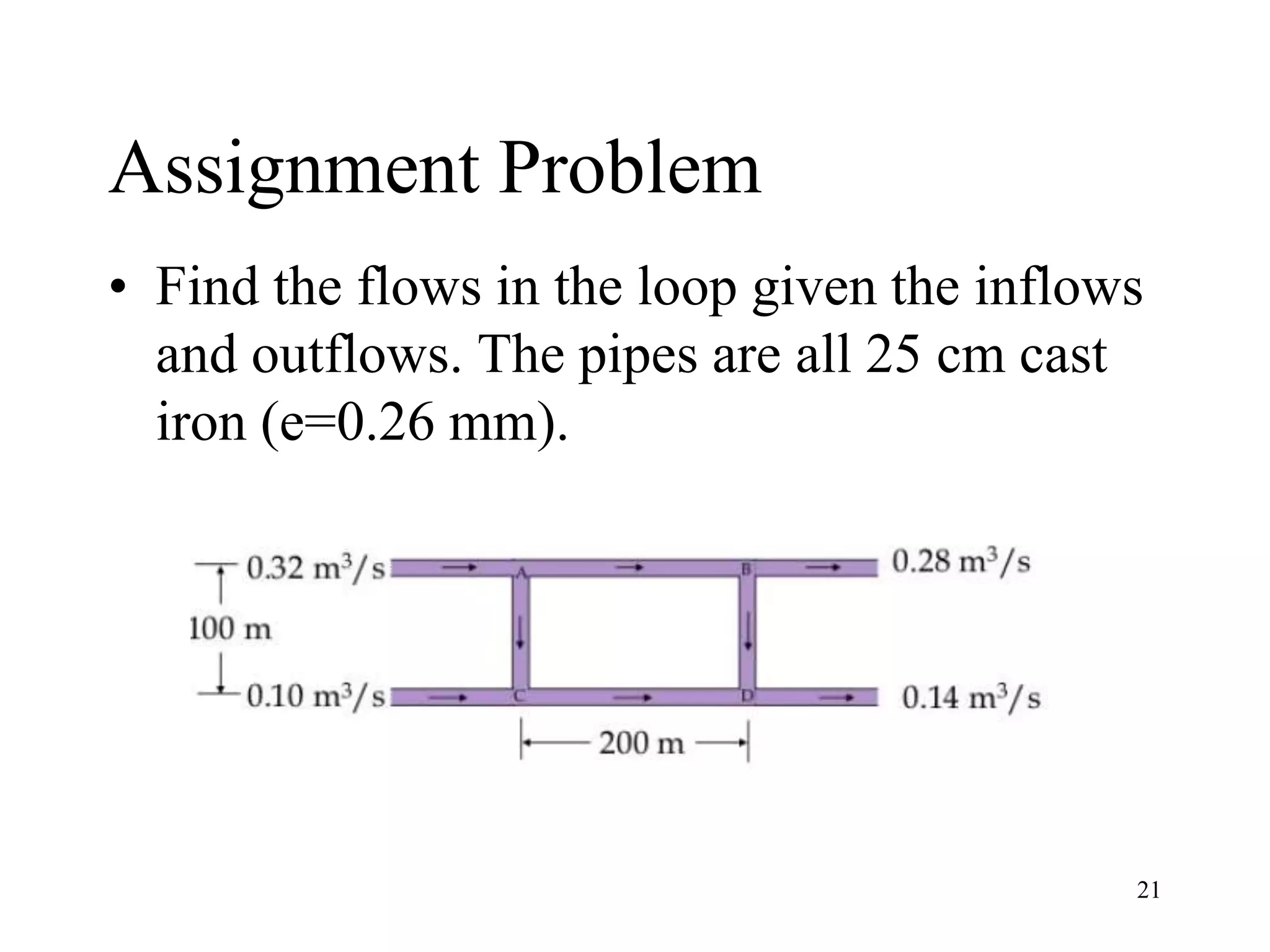

The document outlines pipe network analysis using the Hardy Cross method, an iterative approach applicable to closed-loop systems. It details the principles of continuity and energy equations governing flow rates and head loss calculations, along with examples of applying the method in practical scenarios. The Hardy Cross method is deemed efficient for determining flow rates in a network while maintaining the necessary conditions for accurate head loss assessment.