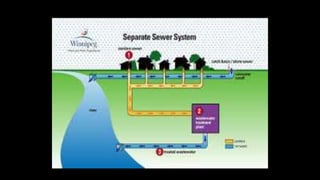

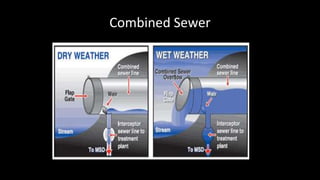

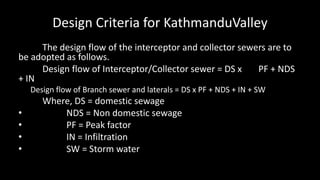

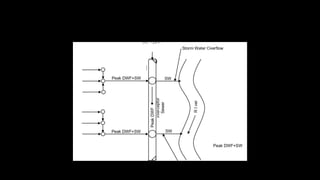

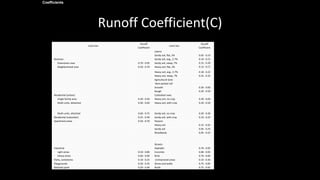

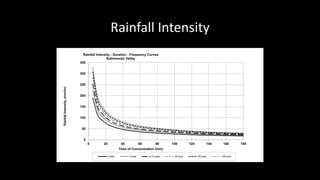

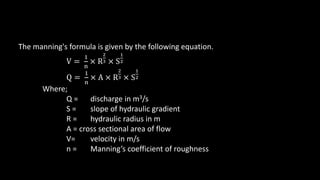

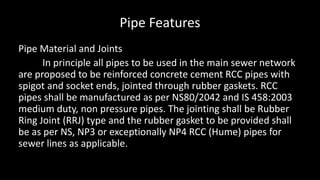

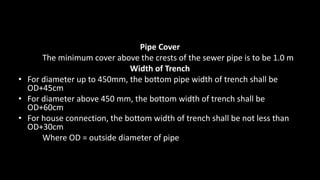

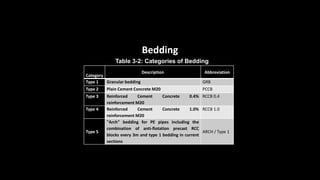

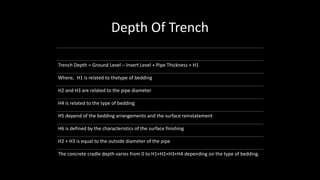

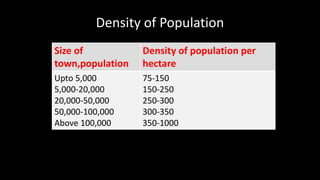

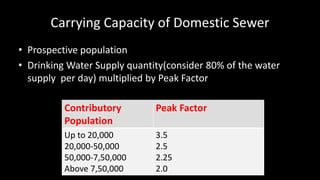

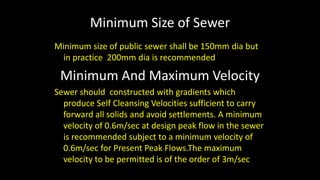

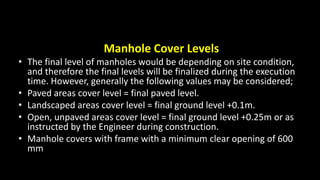

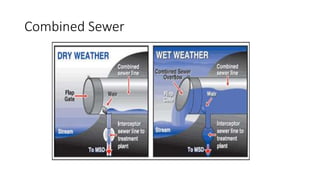

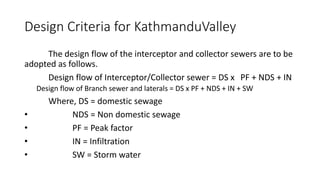

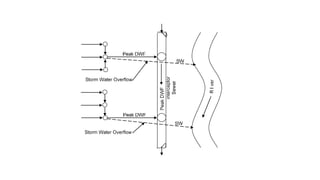

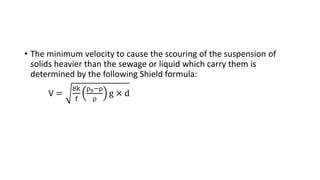

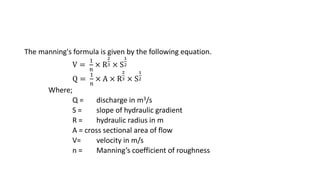

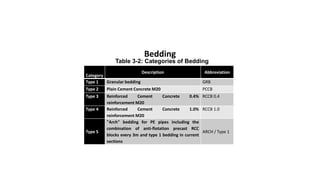

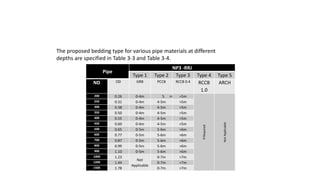

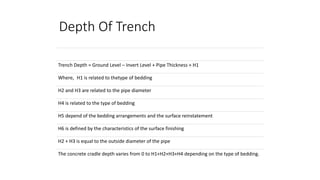

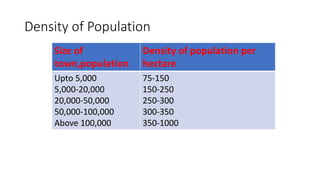

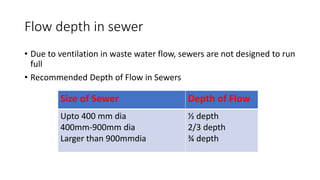

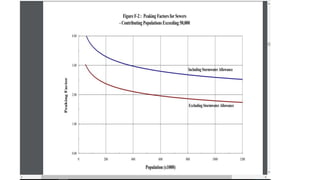

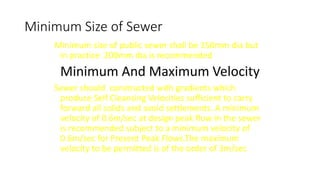

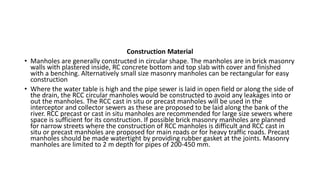

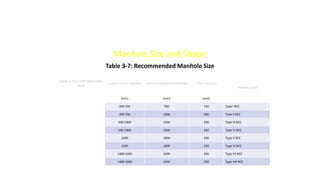

The document outlines the collection and treatment of wastewater, detailing types of wastewater and collection systems (sanitary, combined, and stormwater). It includes design criteria for sewer systems in Kathmandu Valley, focusing on factors such as flow rates, population density, and rainfall intensity. The document also discusses materials, dimensions, and construction standards for sewer pipes and manholes, aiming for effective sewage management and infrastructure durability.