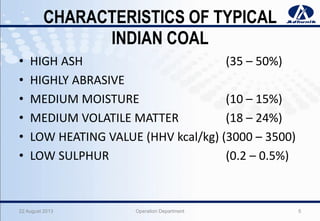

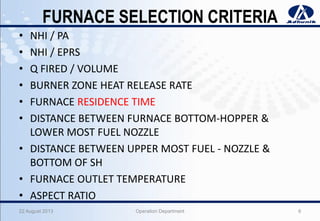

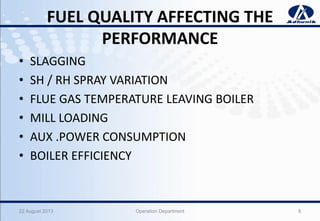

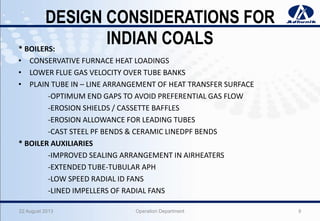

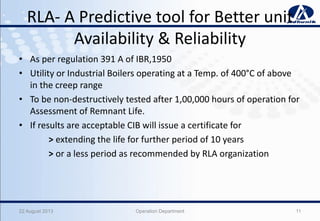

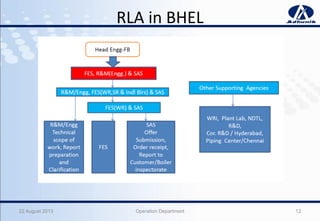

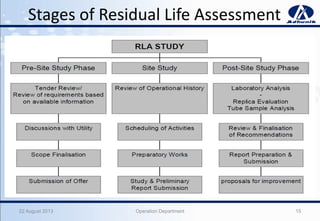

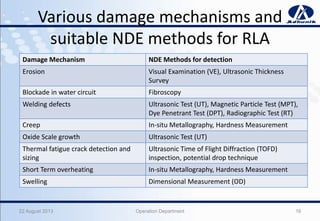

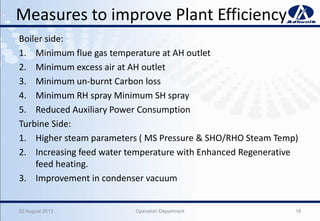

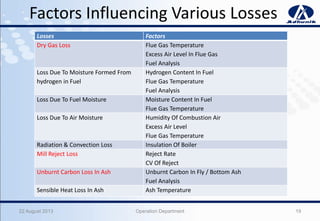

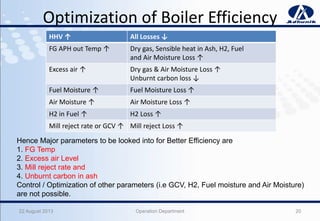

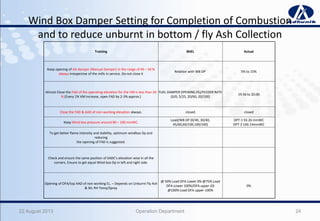

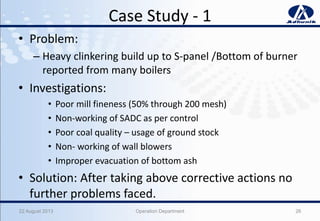

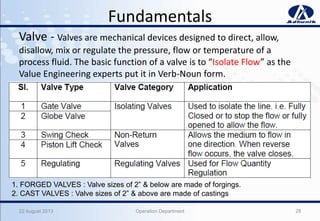

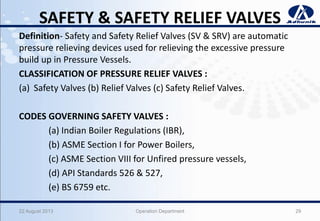

The document provides an overview of topics related to improving boiler performance and extending boiler life. It discusses boiler design considerations for Indian coals, including conservative furnace heat loadings and plain tube arrangements. It also covers life assessment of boilers, combustion optimization measures like minimum flue gas temperature and excess air, and operation and maintenance topics such as valve fundamentals and safety relief valves. Case studies on clinkering buildup issues and questions from attendees are also included.