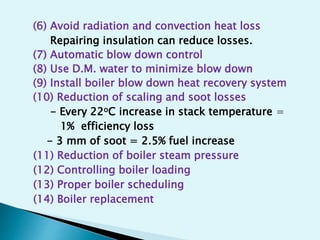

A boiler is a closed vessel that uses heat to convert water into steam. This document discusses different types of boilers, their components, construction features, controls, and efficiency improvements. Fire tube boilers have hot gases pass through tubes submerged in water, while water tube boilers have water pass through tubes surrounded by hot gases. Boilers include safety devices and controls to regulate pressure, water level, fuel supply, and more. Maintaining low excess air and stack temperature, preheating feedwater, and reducing scaling can improve boiler efficiency.