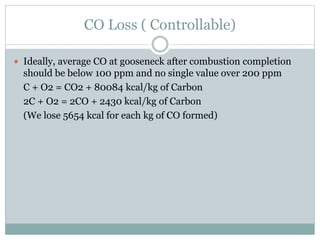

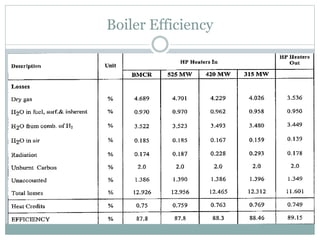

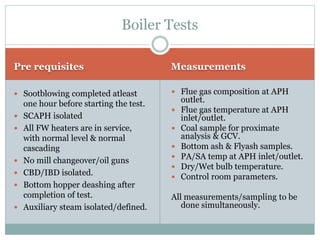

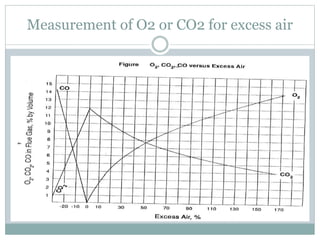

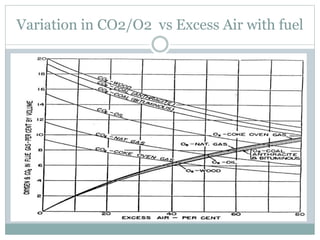

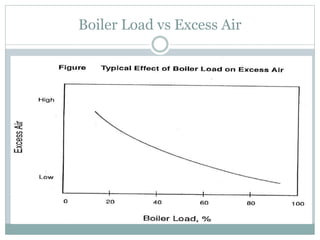

Boiler efficiency is affected by many factors and declines over time without proper maintenance and operation. It is important to regularly test boiler efficiency to identify problems and take corrective actions. There are two main methods for calculating efficiency - direct and indirect. The indirect (heat loss) method involves measuring flue gas and air properties to calculate controllable losses like dry gas loss and carbon monoxide loss. Maintaining optimal excess air levels is important for complete combustion and efficiency.