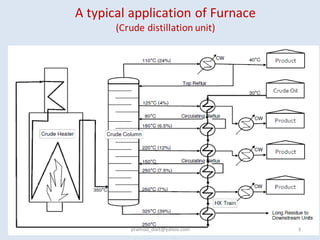

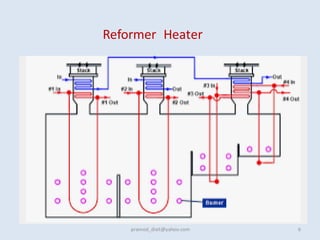

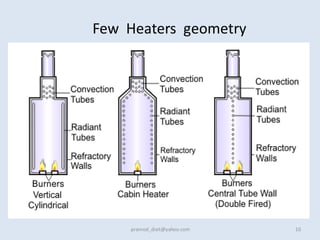

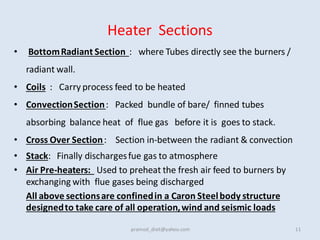

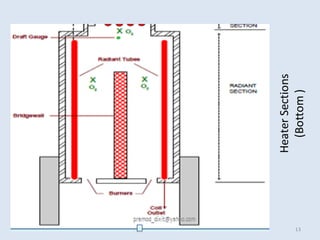

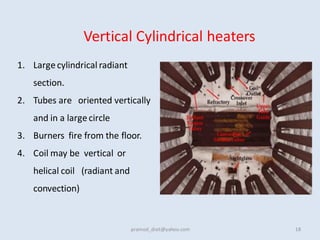

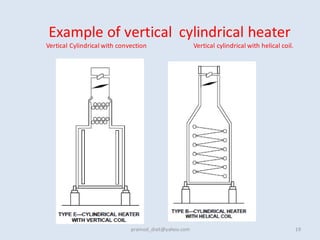

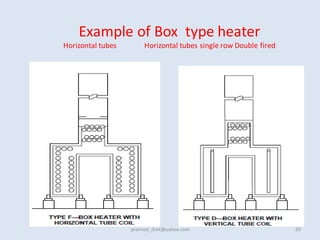

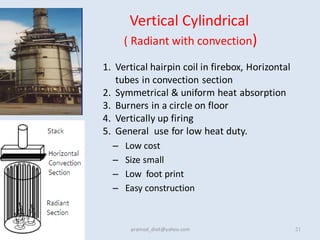

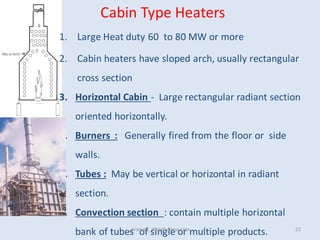

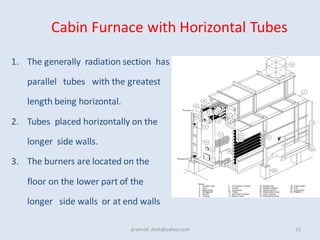

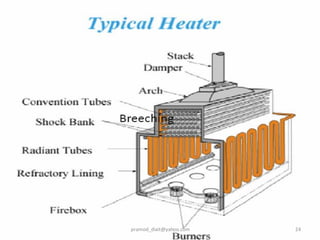

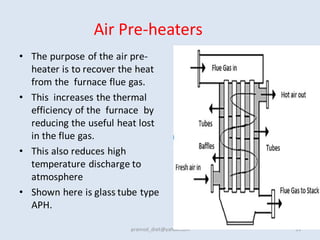

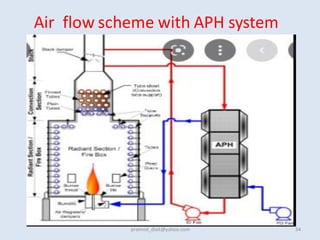

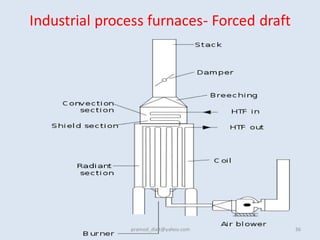

Process furnaces are widely used in petroleum refineries and petrochemical plants to generate heat through the combustion of fuels. This heat is transferred to process fluids inside coil tubes and can range from a few thousand to a few million MW. Common applications include crude distillation units and reaction heaters containing catalysts. Furnaces come in various designs like vertical cylindrical, box type, or cabin furnaces and must maximize heat transfer while minimizing emissions and fuel consumption. Burners, refractory, insulation and controls are important components that require consideration for optimal furnace performance.